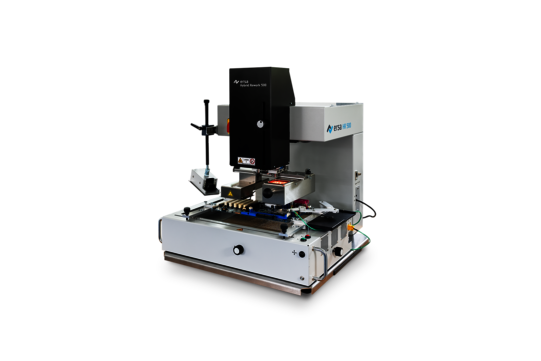

Ersa Dip&Print Station Ersa Rework

Defined flux or solder paste application during rework

The Ersa Dip&Print Station enables the user of Ersa rework systems to carry out component preparation (application of solder paste and flux) easily, reliably and reproducibly. Optional dip stencils allow components to be dipped into flux or solder paste in a defined manner, thus creating a defined depot of solder connections.

Highlights Dip&Print StationErsa Rework

- Suitable for all Ersa rework systems

- Component preparation with solder paste or flux

- Simple, reliable and reproducible application

- Standardized dip stencils for many applications (flux or dip-compatible solder paste)

- Component-specific print stencils according to customer requirements

- Suitable adapters for Ersa rework systems

- Cleaning and drying of the stencils in the station

Dip&Print StationErsa Videos

Ersa Rework System – HR 600 XL – product video (English)

Higher, faster, further! And also bigger: Ersa HR 600 XL – the ultimate solution for professional big board rework up to 24 x 24 inches. See the capabilities and flexibility of this exciting machine.

Ersa Rework – REWORK goes live – Trailer

Ersa Rework – REWORK goes live – Trailer

Dip&Print StationErsa Rework

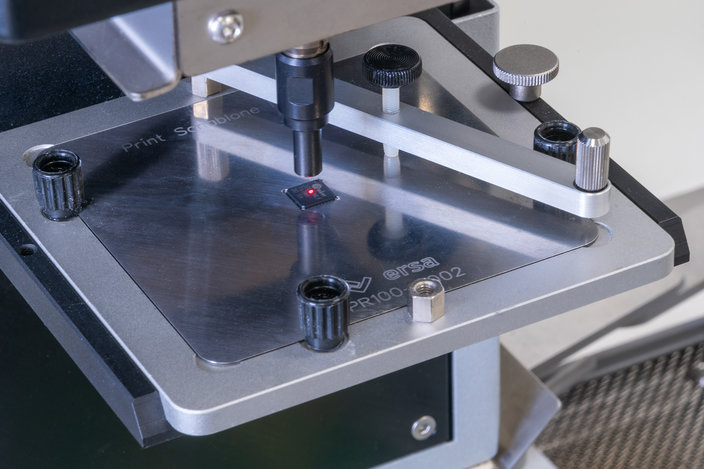

Available options

- Order no. - Designation

- 0PR100-D001 Dip stencil 40 x 40 / 300 µm

- 0PR100-D002 Dip template 20 x 20 / 150 µm

- 0PR100-D003 Dip template 20 x 20 / 100 µm

- 0PR100-D004 Dip stencil 40 x 40 / 100 µm

- 0PR100-R001 Squeegee plate 70 x 25 mm, 0.3 mm thick

- 0PR100-S001 Print stencil, type 1, BGA 225

- 0PR100-S002 Print stencil, type 2, MLF 32

- 0PR100-S003 Print stencil, type 2, QFN 20

Other dip and print stencils available - customized stencils on request.