02/2024 | User Report Rework

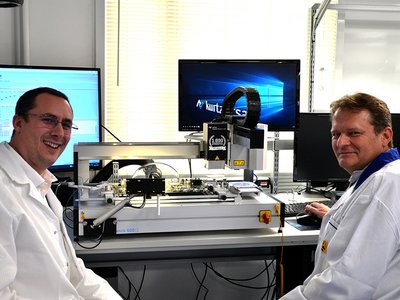

Eric Delmas, CEO of Analog Way, is beaming all over his face as he receives the Ersa delegation. There are several reasons for his engaging smile – for one thing, Cyril Decombaz and Martin Dosch have come together with Jörg Nolte to congratulate Analog Way on the acquisition of the hybrid rework system with the serial number 1,000. On the other hand, the company can look back on a great success story and sees itself in an excellent position for the future.

Analog Way, based in Antony south of Paris, develops professional audiovisual equipment. Behind the name LivePremier™, for example, is a complete range of modular and scalable multi-screen presentation systems and video wall processors able to drive pixel canvases up to 32K. The systems are specially developed to meet the highest requirements in mission-critical applications. The modular design of these high-end devices allows easy exchange of inputs and outputs cards to suit numerous connectivity options and their source and display demands.

The fields of application are as diverse as they are unique – video walls at Times Square in New York are controlled with Analog Way systems, as are backwalls for television or cinema productions. Users include event technology companies, casinos, museums and operators of gigantic video advertising spaces or control centers with their complex display systems and modern engineering centers.

According to Eric Delmas, acceleration of end market diversification is one of the foundations to Analog Way´s booming success. Founded in 1989, the company has developed steadily. Now with over 100 employees and an international presence, it has experienced dynamic growth in recent years, well ahead of the general market trend. It is therefore understandable that Analog Way seeks to strengthen its expertise in product maintenance. The company considers itself well-positioned to continue the development and maintenance of its products in Europe and aims to invest by equipping its own site. It is in this approach that the HR 600/2 repair system from Ersa was recently purchased, with the mission of both repair and research and development. Production Manager Hugues Marlard emphasizes that the company places great importance on speed and quality in both of these areas. Although the Analog Way systems have a modular design and many installations are designed redundantly, things have to move quickly in the event of a repair. However, the quality of the repair is the top priority. With this in mind, the Ersa system was chosen on the recommendation of several partners of Analog Way.

In practice, both Ball Grid Arrays (BGA) and integrated circuits in Quad Flat Pack (QFP) as well as other types of housing are replaced on complex multi-layer boards. Repairs are also carried out on HDMI or Display Port connectors. Quite often, these component changes are initiated by the development department, which, for example, would like to examine failed components more closely after cycle tests. With the help of the automated rework system, the in-house developers can retool or retrofit assemblies much faster than would be possible without such a device. A particular strength of the Ersa rework device is its high level of flexibility – components from 1 x 1 mm to 60 x 60 mm can be processed without any additional accessories. The HR 600/2´s ability to successfully desolder or solder a component on the first attempt is also impressive. In addition to the automated rework process, this is also due to the precise temperature control on the target component. Gentle and extensive heating of the assembly is a key criterion here. “It is an honor for me to be at the head of a team in which innovative employees work together to realize extremely successful solutions – I am proud of what we have achieved so far as Analog Way and I am confident that we will continue to develop positively – thanks in part to the active support from Ersa,” concludes Analog Way CEO Eric Delmas.