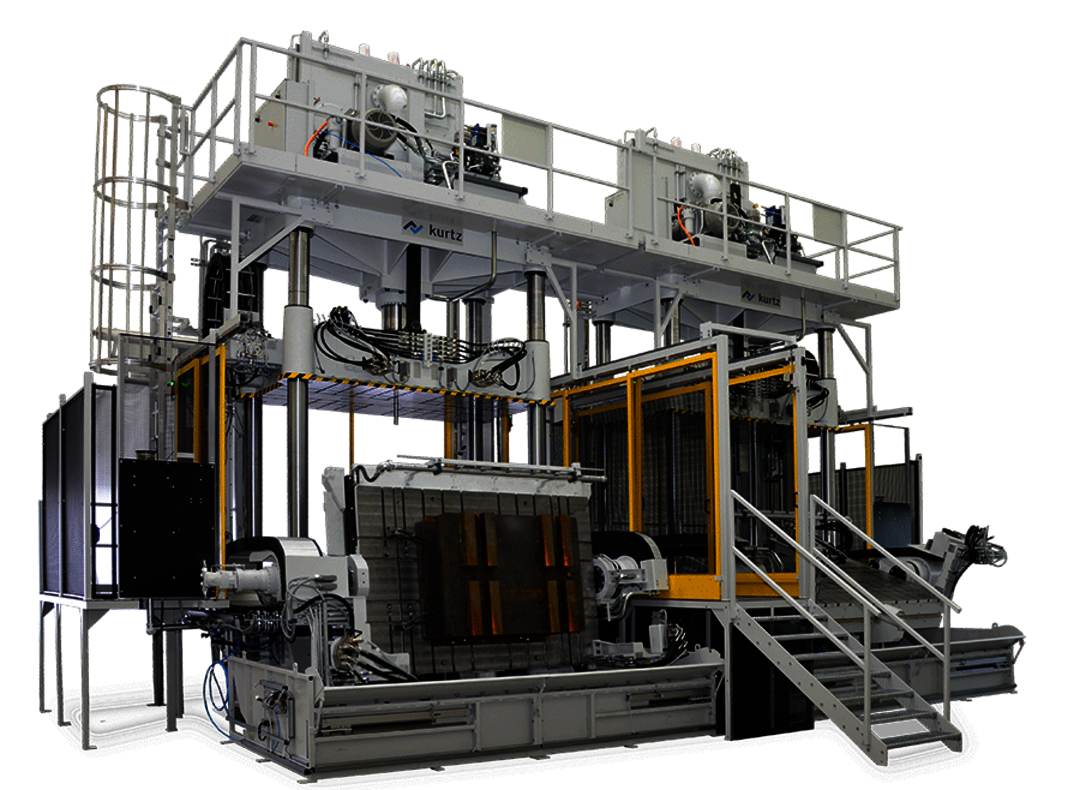

And it does work: GIGA press for GIGA casting!

While the removal of filters, gatings and overflows with trimming presses was a MUST for parts cast in high pressure so far, GIGA castings were not deburred using the proven technology at the beginning. Castings and required tools as well as presses were considered too large and not economically feasible. Now you could say: “And it works after all!”

Until now, Kurtz trimming presses have worked in die casting cells with a clamping force of up to 6,000 tons. Kurtz received its first inquiries about trimming GIGA castings with GIGA presses from Asia. Initially, the trimming of castings produced on high pressure casting machines with a clamping force of up to 9,000 tons was discussed. There are numerous reasons why to rely on the proven technology also for GIGA castings – i.e. trimming directly in the high pressure casting cell. Detailed advantages:

- Less logistical effort

- Shorter trimming process, shorter distances and therefore less expensive

- Efficient process flow similar to existing automation sequences from the established high pressure casting process

- Cost-efficient thanks to reduced footprint and fewer subsequent handling processes

- Simple and safe operation

- Quick findings regarding quality directly after the casting process

Trend back to the trimming press also recognizable for GIGA castings in Europe

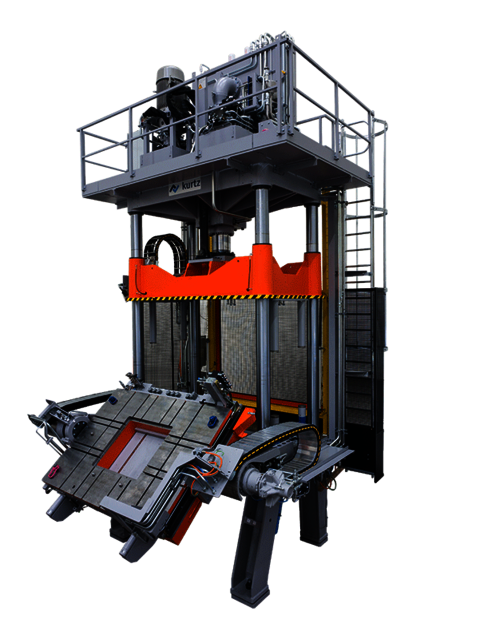

The requirements for the GIGA presses were the same as before, apart from two challenges: the clamping surface – and therefore the size of the tool – and the weight. The necessary cutting force was available, as Kurtz had already built several presses with 300 tons of punching or cutting force. The requirement for the clamping surface was 4,000 x 3,000 mm and the presses had to be able to hold tools weighing up to 25 tons.

Whereas structural parts are mostly trimmed on presses with sliding/tilting table, the “standard” 4-column press is the preferred choice for these dimensions. The advantage of such a press is that less space is required in the high pressure casting cell. However, more attention must be paid to the burr removal during tool construction.

Despite the size of the presses, they must not slow down. Development in high pressure casting is known to be rapid – which means that the cycle times in casting are also becoming shorter. The press must not slow down the casting process. If you deduct the loading and unloading time of the press using robots, there is not much time left for the trimming process itself.

Fast presses are therefore necessary, comparable to the well-known large presses from the Kurtz range. In addition to the standard requirements for presses, sufficient slider connections should be available due to the more complex shape of the castings. Previous experience shows that up to ten sliders can be required.

Das gesammelte Know-how im Bau von Entgratpressen und GIGA-Niederdruck-Gießmaschinen kommt Kurtz in Konzeption und Bau von GIGA-Pressen zugute. Dreh- und Angelpunkt ist neben einer schnellen und leistungsstarken Hydraulik vor allem die Software. Bewährt hat sich der von Kurtz entwickelte Werkzeugschutz, der bei GIGA-Pressen erst recht Anwendung findet.

Denn Schaden und Ausfall an großen Entgrat-Werkzeugen schmerzen noch mehr, als dies schon bei herkömmlichen Werkzeugen der Fall ist. Aktuell haben wir Anfragen für Pressen zur Installation neben Druckgussmaschinen bis 12.000 Tonnen Schließkraft. Die angefragte Schnittkraft liegt bei 400 Tonnen.

Equipment features Kurtz GIGA trimming presses:

- Clamping surface: 4,000 x 3,000 mm

- Tool weight: 25 tons

- Cutting force: 300 tons

- Slider connections: 10

- Parallel movements

- Spraying unit system for minimum lubrication

- Tool protection

- Freely programmable speed profile

- Parameters saved in recipe management

- Transportable mobile panel

- Condition monitoring

- Consumption measurements

- Maximum energy efficiency thanks to speed-controlled motor-pump drives

- Simple maintenance

- Intelligent machine control

- Noise development/volume less than 75 dB(A)

- Central position for all consumables

Ausstattungsmerkmale für Kurtz GIGA-Entgratpressen:

- Aufspannfläche: 4.000 x 3.000 mm

- Werkzeuggewicht: 25 Tonnen

- Schnittkraft: 300 Tonnen

- Schieberanschlüsse: 10

- Minimalmengenschmierung

- Werkzeugschutz

- Transportables Mobiles Panel

- Parallelbewegungen

- Geschwindigkeitsprofil frei programmierbar

- Parameter in Rezeptverwaltung gespeichert

- Condition Monitoring

- Verbrauchsmessungen

- höchste Energieeffizienz durch drehzahlgeregelte Motor-Pumpen-Antriebe

- einfachste Wartung

- intelligente Maschinensteuerung

- Geräuschentwicklung/Lautstärke kleiner 75 dB(A)

- zentrale Position für alle Verbrauchsmedien