All good things come in threes!

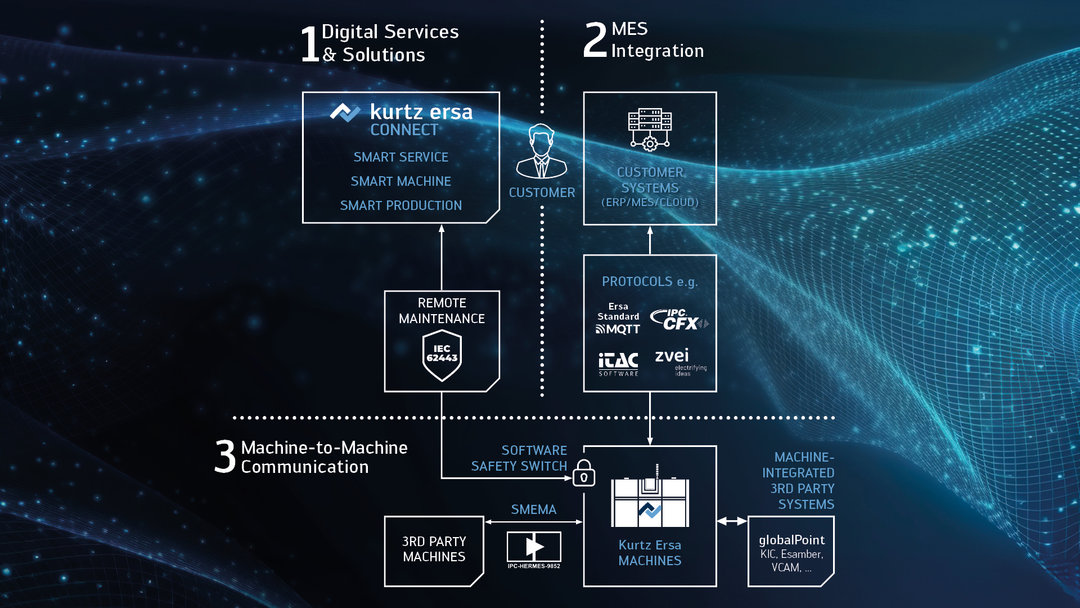

At Kurtz Ersa, we understand the challenges of modern electronics production. With Kurtz Ersa CONNECT, we offer you the modular platform that intelligently networks your production systems and increases the efficiency of your processes. Our solution adapts flexibly to your needs and supports you and your employees in the future-proof digitization of your production:

1. Digital Services & Solutions

2. MES Integration

3. Machine-to-Machine Communication

Simply explained and perfectly implemented. Put your trust in our comprehensive expertise and contact us! We take responsibility!

1. Digital Services & Solutions Kurtz Ersa CONNECT

The digital offerings of the Kurtz Ersa CONNECT platform can be accessed from any location and device via a web browser from any internet-enabled computer/mobile device.

SMART SERVICE

Easy and fast service request via Phone or service-form ensure the efficiency of our service process. Our remote service tools allow us to start the action immediately even without onside visit.

Benefits:

- Higher machine availability

- Greater speed in the service processes

SMART PRODUCTION

With our wide range on interfaces, we provide multiple solutions to connect the machine to supervisory control systems. On one hand with our own → solution provided by Schiller and on the other hand the compatibility through standard interfaces for effective process and machine monitoring.

Benefits:

- Important information can be evaluated directly on the basis of the collected data, making production more efficient

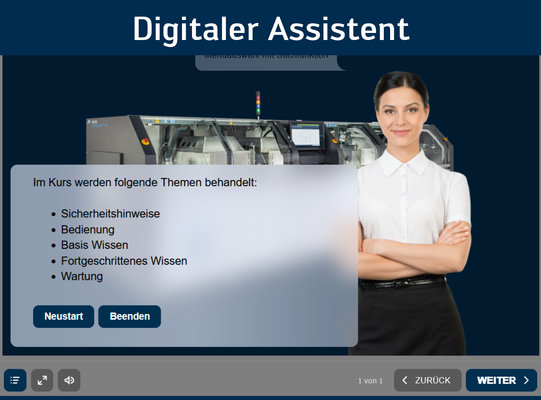

- Knowledge is the simple key to machine and process expertise; that´s why we offer you all relevant courses on our → eLearning platform

2. MES Integration & Smart Production

Automate your production processes by integrating them into existing MES systems. For seamless MES integration our machines support multiple standard interfaces. As a member of the IPC-CFX standard task group we support the development of this open industry standard. Our software core provides control functions as well as traceability and process data. This allows us also to provide customized MES-interfaces.

Benefits:

- Standard interfaces for fast and easy integration

- Customized solutions for best fit

3. Machine-to-Machine Communication

Network your machines to optimize production processes and set new efficiency standards. Our machines support the signal-based board handling via SMEMA. As a part of the Hermes Messengers, we participate in the development of the IPC-HERMES-9852 Standard. HERMES is protocol based and the generic communication backbone of the production line.

Benefits:

- Exchange of PCB-relevant data, e.g. product dimensions

- Automatic change of soldering programs

- Automatic change of transport widths

- Board tracking along entire line with single board ID reading

- Adaptable for further and future requirements