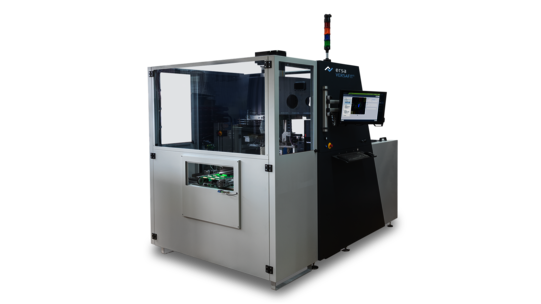

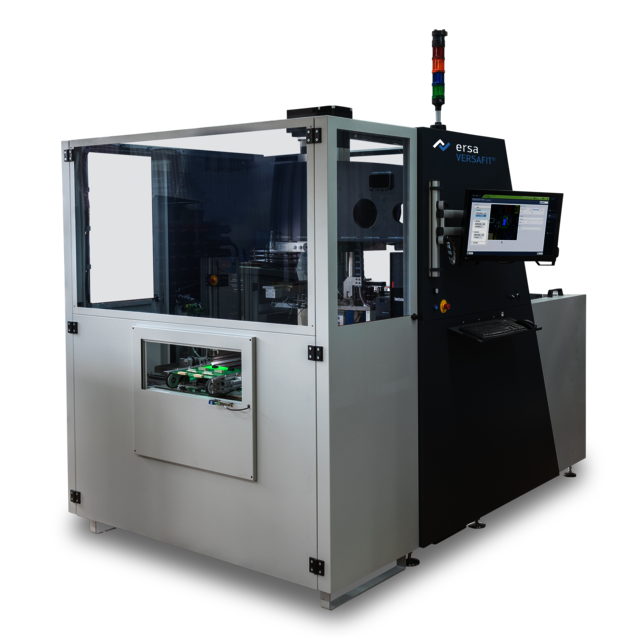

Press-fit technology has experienced significant growth in recent years. This well-established technology is becoming increasingly important in power electronics. Ersa’s VERSAFIT models meet this demand, offering maximum precision and performance. Whether for IGBT power modules, high-pin connectors, high-mix manufacturing or largescale production, the VERSAFIT family offers the perfect balance of quality, cost-effectiveness and sustainability.

Next Level Joining Technology: Press-fit technology has been around since the 1970s. Until now, it has primarily been used for connectors and individual pins in the telecommunications sector. However, in an era of ever-increasing performance and currents, press-fit technology can be utilised much more broadly. Significantly lower contact resistance and higher reliability make the technology particularly interesting for power electronics. In the battle for every percentage point of efficiency, pressfit connections can outperform soldering. Furthermore, more and more applications are reaching dimensions that soldering can no longer physically accommodate.

Know-how in Press-fit Technology

Contact physics and metallurgy

Contact physics and metallurgy

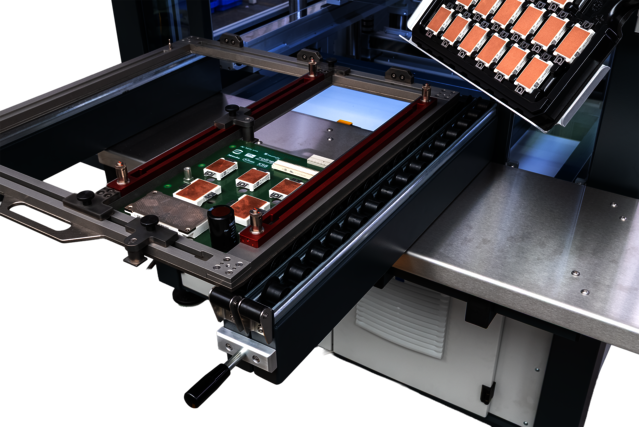

During press-fitting, oversized pins are always pressed into a smaller hole. Pins are available in various shapes (flexible and solid). This requires a force that deforms one or both joining partners. This creates

intensive metallic contact. This contact is further intensified by diffusion processes and is fully formed after around 24 hours.

Conductivity and reliability

Conductivity and reliability

Due to the direct metal contact, the contact resistances of press-fit connections are generally lower than soldered connections, despite their smaller cross-sectional area. This also means that losses are lower at high currents. In addition, the reliability of press-fit connections is also better. Mechanical stresses damage them significantly less than soldered connections.

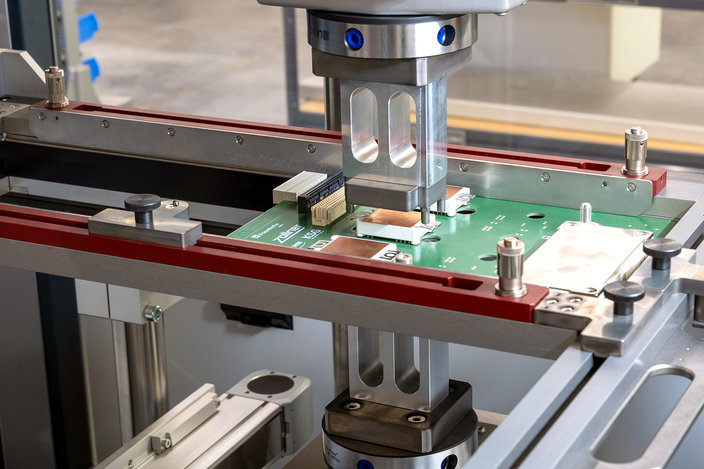

Process control using force

Process control using force

The ideal process control is force-displacement monitoring. A sensor records the force during the pressing process, creating a characteristic curve. This can be used for both process monitoring and process control if the pressing process runs automatically. The termination criterion of the press can be defined by means of freely definable monitoring windows, which considerably reduces the stress on the assembly and components. Another important parameter is the number of pins that define the force.

Flatness is key

Flatness is key

Power semiconductor modules in particular require a high degree of flatness so that they can be effectively connected to cooling units. The use of press-fit tools with spacers enables the highest standards of flatness. The design for a selective pressing process with smaller tools prevents tilting due to tolerances during pressing. A stable machine construction with a closed frame prevents twisting, which can occur with C-profiles and high forces.