VERSAFIT ONE - semi-automatic press-fit system for process reliability Ersa Press-Fit Systems

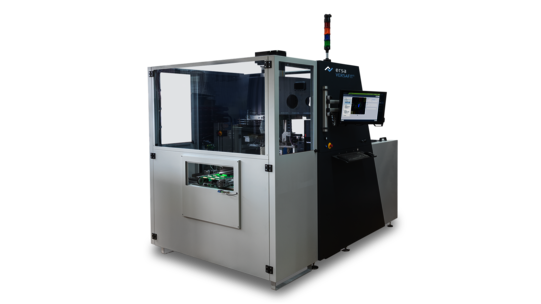

With the VERSAFIT ONE, Ersa presents a new generation of semi-automatic press-fit systems. The compact batch machine sets standards in precision, process reliability, and cost-effectiveness - ideal for medium-sized manufacturing companies with a high product mix. It combines the proven technology of the high-end VERSAFIT 500 system with a new, space-saving concept. By dispensing with inline capability, the size of the machine has been reduced and an attractive price-performance ratio achieved.

VERSAFIT ONE | TECHNICAL HIGHLIGHTS

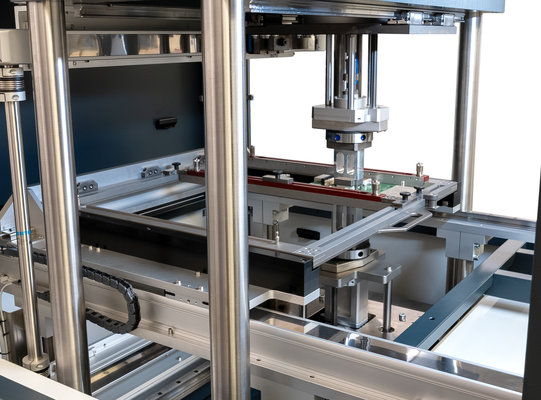

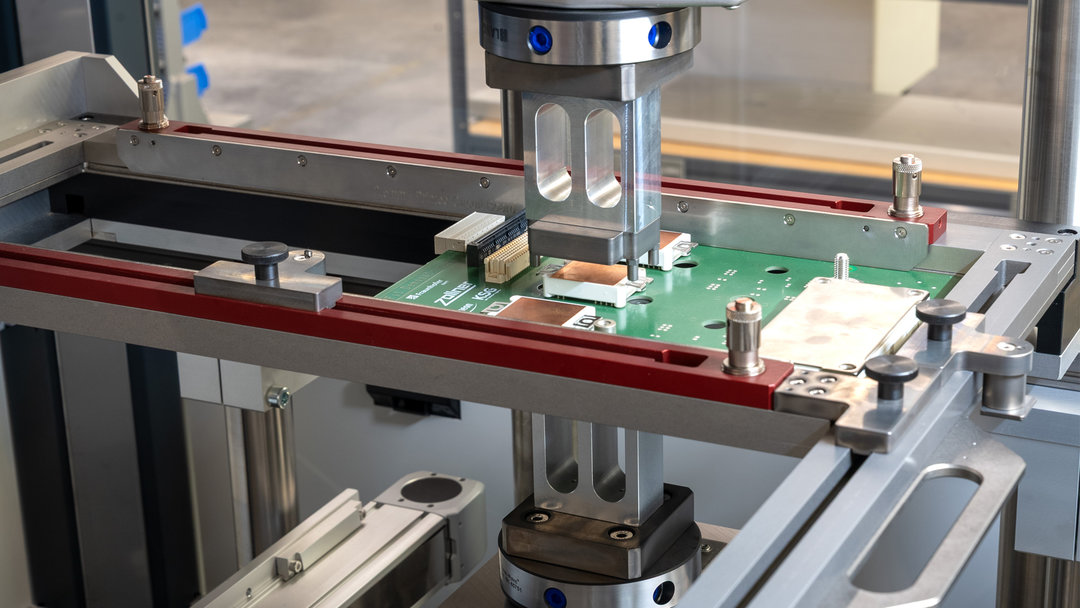

- Servo-electric press cylinder

- High flexibility

- Permanent process monitoring

- Easy maintenance

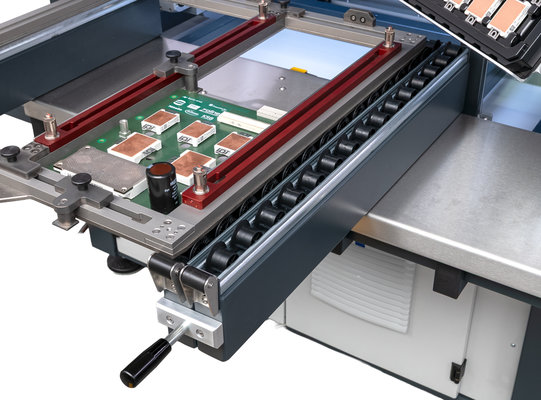

- Transport with slide rails for goods carriers

- Loading table with roller transport

VERSAFIT ONE | FEATURES

VERSAFIT ONE

Complete process monitoringErsa VERSAFIT ONE

The VERSAFIT ONE offers complete benchmark-level process monitoring, including force-displacement measurement with up to 20 freely definable windows per component and real-time OK/NOK evaluation. With clearance heights of 100 mm at the top and 120 mm at the bottom, it processes assemblies up to 610 x 610 mm. The robust, user-friendly technology is based on the Ersa batch selective soldering platform and guarantees the highest quality without thermal stress or flux. The result: lowest contact resistance and heavy-duty connections for high-power applications. This makes the VERSAFIT ONE the economical solution between manual presses and fully automated lines – ideal for photovoltaics, e-mobility, energy, and charging infrastructure.

VERSAFIT ONEErsa Press-Fit Systems

Technical data

Length:

1,600 mm x 800 mm loading table

Width:

1,400 mm

Height:

2,010 mm

Press-Fit

Press force:

5 kN

Linearity force sensor:

+/-5% FSO adjustable measuring range

Tool magazine (optional):

external manual - for 10 tools

Tool length:

max. 150 mm

PCB conveyor

PCB width:

max. 610 mm

PCB length:

max. 610 mm

PTB bottom-side clearance:

max. 120 mm

Options

- Shifting table for additional product carriers

- Storage for component blisters (400 x 300 mm)

- Traceability/MES

- PCB thickness measurement

- Automatic tool rotation

- Force testing equipment

- Tool storage in the machine

- Up to 5 upper and lower tools