SCHILLER AUTOMATION has developed a new dispensing cell based on numerous individually designed dispensing cells with different dosing and preparation systems. The modular design of the cell allows for a high degree of flexibility in order to take specific requirements in terms of component transport and dispensing technology into account. The transport medium can be freely selected, which further increases adaptability. A key advantage of this solution is that commercially available dosing units can be easily integrated.

The use of materials with different viscosities opens up many possibilities. For example, potting compounds can be used to protect and passivate components, while adhesives ensure that components are securely bonded together. Lubricants can also be applied precisely where they can be most effective.

Features of Dispense SolutionsKurtz Ersa Factory Automation

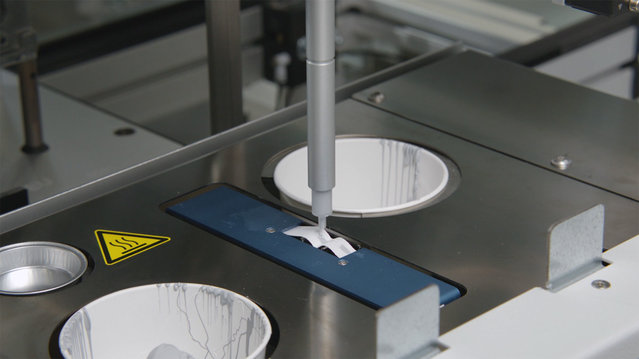

The dispensing cell from SCHILLER AUTOMATION ensures that the required amount of material is always applied precisely to the right place. The integrated X/Y/Z portal makes it possible to move to specific positions and apply material along CNC contours. In addition, automatic needle control and needle cleaning are integrated, as is a scale with a collection container for precise dosing control. Our dispensing solutions combine advanced technologies with flexible programming to ensure maximum accuracy and efficiency in your production processes.

TECHNICAL HIGHLIGHTS

- Workpiece carrier or workpiece centering

- Free programming of dispensing contour via G-code

- Dispensing head manufacturer independent

- Needle measurement XYZ with offset correction and adjustable limit values

- Built-in CMK/CM measurement for needle XYZ and dispensing quantity

- Precision scale for dispensing quantity control

- Needle cleaning/sealing pad

- Rinsing cup

- Dispensing material cross-linking test

- Replacement of disposable items mostly without production interruption

Our dispense solutions are the optimal choice for companies seeking solutions to improve their automation processes and maximize the quality of their products. Let us work together to find out how our dispense solutions can achieve exactly what you need!