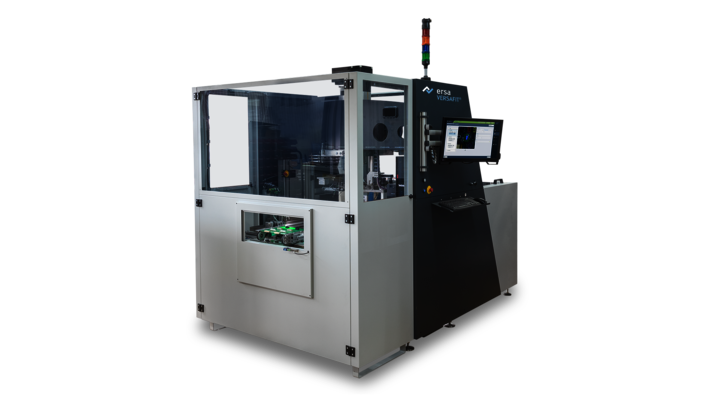

VERSAFIT 500 - Inline-Pressfit System for maximum throughput Ersa Press-Fit Systems

VERSAFIT 500 | TECHNICAL HIGHLIGHTS

Servo-electric press cylinder

High-precision x/y table

Tool magazine for up to 10 tools (5 above, 5 below)

High flexibility

Tool selection via control program

Permanent process monitoring

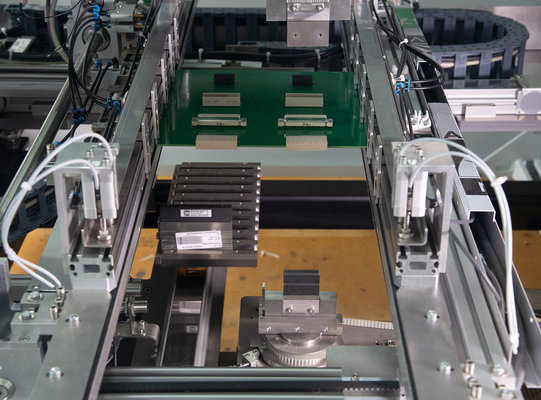

Flat belt transport

Very easy to maintain

VERSAFIT 500 | FEATURES

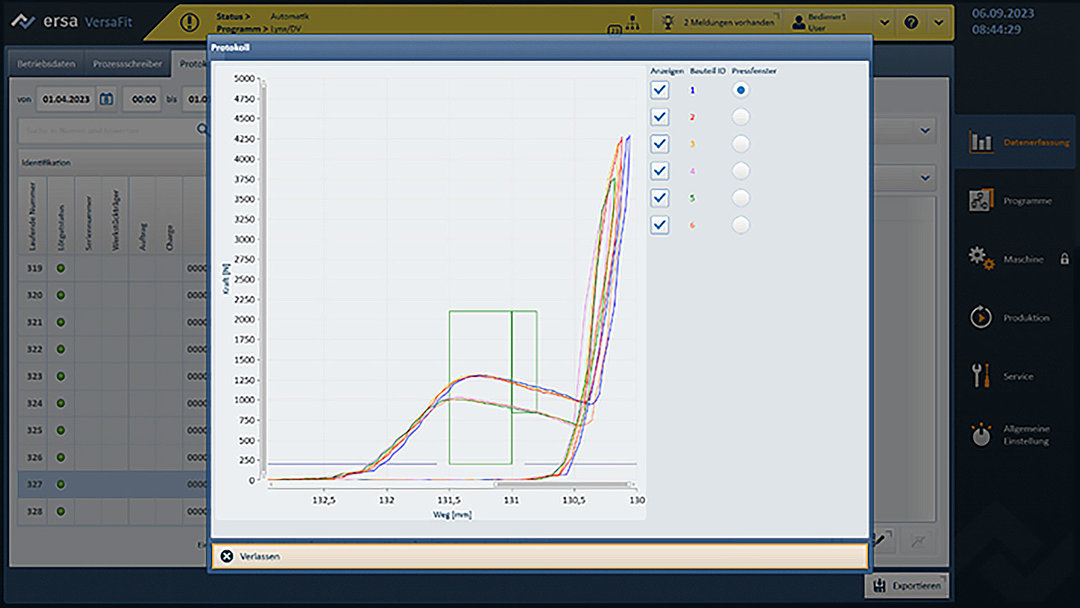

Traceability and process dataVERSAFIT 500

Building on Ersa´ s extensive experience in integrating production equipment into MES, ERP, and traceability system infrastructures, the VERSAFIT 500's control system and software ensure complete process control of the press-fit operation. The data collected in this way is available to the user in various formats and can be processed accordingly.

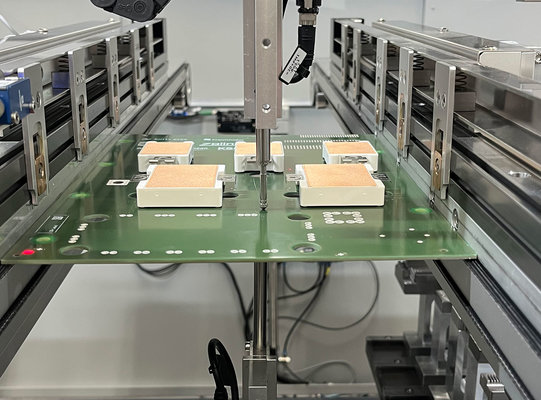

Flexibility and precision

In order to meet the requirements for high flexibility, the VERSAFIT 500 has a magazine for a wide variety of press-in tools. The user defines the tool change or selection and orientation - as well as the associated process parameters - in the control program. The programs are selected and activated via coding of the assembly or workpiece carrier.

Programming is based on automatic placement machines. The position of the x/y table under the press cylinder is determined by the position of the components on the assembly. The number of pins per component and the geometry of the press-fit zones determine the press force, which is recorded as a function of the punch travel to produce the force-travel diagram of the component. Process monitoring is carried out using envelope curves with selectable tolerance fields in the force-displacement diagram.

VERSAFIT 500Ersa Press-Fit Systems

Technical data

Press-Fit

PCB conveyor

Basic configuration

- Individual width adjustment

- Tool rotator

- ERSASOFT 5

- Integrated control cabinet

- Touchscreen operation on the computer

- x/y axis adjustment and password protection