The Additive Manufacturing (AM) business unit is the youngest in the Kurtz Ersa Group. A dedicated team has significantly increased the pace of technical progress in recent months - among other things by introducing agile project management and actively obtaining customer feedback.

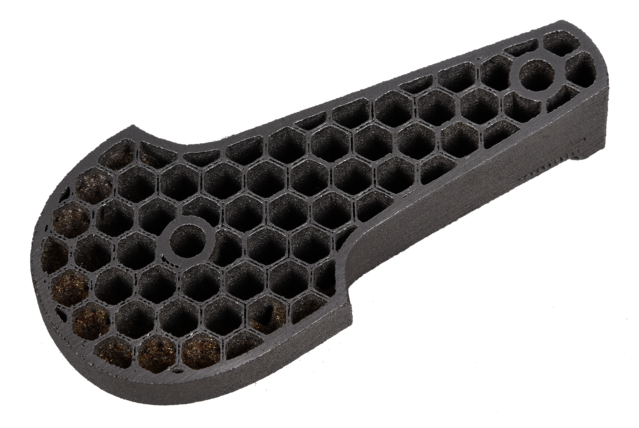

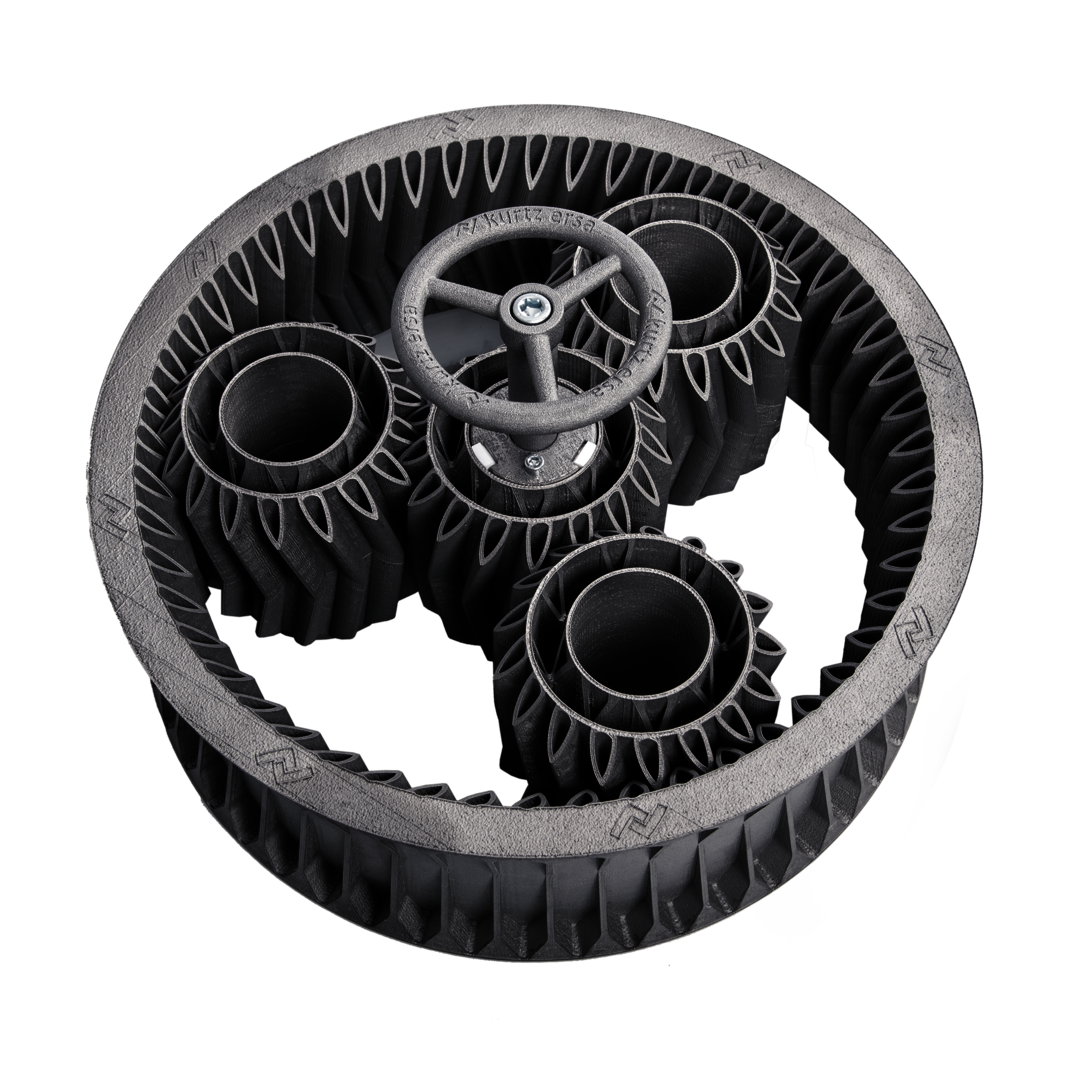

Following its entry into additive manufacturing in 2021, Kurtz Ersa has since regularly achieved important milestones in metal 3D printing. First, a compact, high-performance printer was introduced specifically for SMEs, research & development and training purposes. This cost-effective entry-level device enabled companies to integrate 3D printing into their work processes and discover new possibilities in production. The next milestone followed with the introduction of swivel arm technology. The “Perfect Angle Printing” method redefines the manufacturing process and offers strong advantages such as a constant laser deflection angle over the entire build area, a defined spot on the entire build platform and constant laser intensity. This results in consistent flow and energy input ratios every time the laser beam hits the part. This is the basis for identical component properties across the entire surface and enables true scalability and modular construction of systems with different build field sizes.

Additive manufacturing - independent business division

In 2023, the Additive Manufacturing division was established as an independent business unit with a distinct start-up character. Kurtz Ersa thus committed itself to continuous development in this dynamic sector. The focus has now shifted to quality and process-side development. In the current year, the AM team is concentrating in particular on customer-oriented issues. This is based on the diverse requirements from customer discussions and the results of a customer survey.

AM recognized as a driver of innovation

The German government is also taking a closer look at additive manufacturing and 3D printing and wants to promote them in the future. Alongside lightweight construction, artificial intelligence and robotics solutions, the technologies are recognized as part of the innovation boost for the German economy. The VDMA´s Additive Manufacturing Working Group has contributed to the inclusion of the topic of additive manufacturing in the coalition agreement. AM will make a significant contribution to efficient mechanical and plant engineering.

Agile project management was introduced at the same time, with work being structured in “sprints” every two weeks. The individual team members commit to results that they want to achieve independently in two weeks. The results are then presented to the rest of the team and new goals are planned. After six sprints have been completed, the results achieved are presented to a wider group of stakeholders – such as purchasing, production, service and quality – in order to achieve further transparency and obtain early feedback for subsequent implementation. The team gains speed and structure as a result and at the same time gives room for innovative ideas.

Scalability in production

An important milestone was reached with a project that laid the foundation for the so-called Flying Ray S – a system with an installation space of 250 x 250 x 300 mm. The first entry-level system with swivel arm technology. This commitment is part of a larger plan to promote scalability in production by guaranteeing that the starting system of installation space size S offers the same process conditions as an upscaled large-format system. The homogeneous energy input is realized through the use of swivel arm technology, which avoids distortions caused by laser beam deflection and thus ensures the highest quality. At Kurtz Ersa, a process developed on small systems is transferred 1:1 to larger machine types in this way – without separate additional process development. This provides companies with a robust and flexible solution that grows with their production requirements.

Comprehensive solutions for customers

Stronger cooperation with other divisions of the Group – for example in the field of automation – also helps customers to benefit from comprehensive solutions. Kurtz Ersa thus offers a further unique selling point. Dr.-Ing. Astrid Rota, Managing Director Additive Manufacturing, looks back on her time at Kurtz Ersa so far: “The team thinks innovatively in all directions when finding solutions and retains its start-up spirit. I am very proud of what we have already achieved together in such a short time.”