EPP Pre-Expander Pre-Expander

Reduction of material use and conservation of resources

Advantages Kurtz EPP Pre-ExpandersEPP Pre-Expander

Uniform bulk density distribution

Homogeneous temperature distribution in the pre-expansion vessel

Stabilization of EPS beads in the fluidized bed

High material throughput

Low energy consumption

EPP Pre-Expander

Highest Efficiency

With the use of a Kurtz EPP pre-expander, a truck can transport up to five times the raw material weight per trip, resulting in enormous cost savings. The potential savings in raw material consumption that can thus be achieved make it possible to amortize the cost of the investment within 2 years at a throughput of approximately 100 t per month.

Pre-foaming process: first step to success

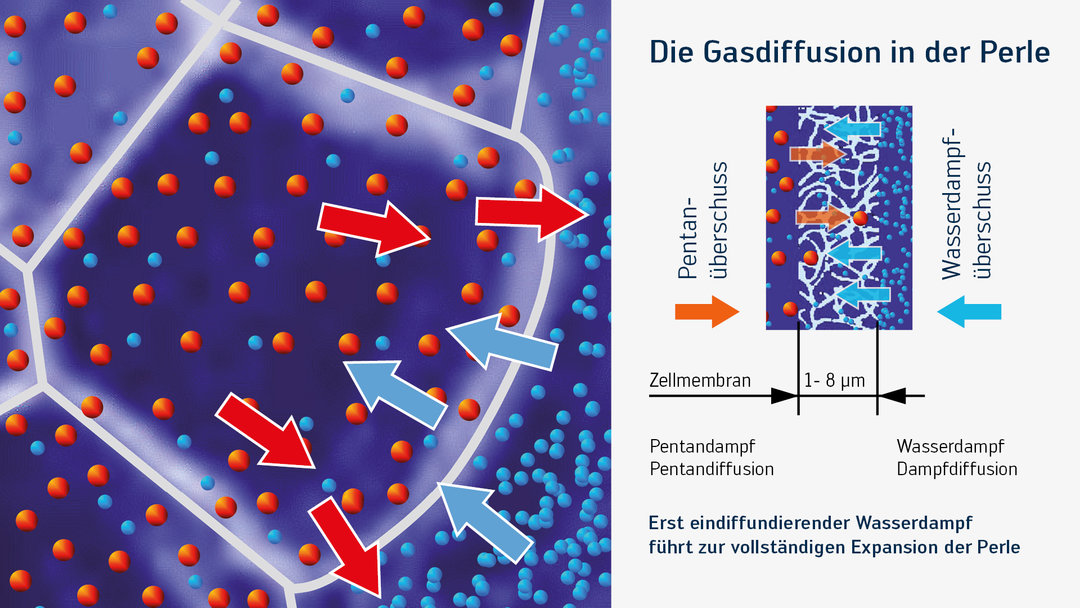

The EPS raw material is conveyed as granules to the preexpander, where it is heated by means of wet steam. The hot steam softens the polystyrene beads and activates the blowing agent dissolved in them. This evaporates and causes the softened beads to expand. The bulk density can be adjusted by the weight of the raw material and the foamed volume. The EPS beads pre-expanded in this way are then cooled and stabilized in a fluidized bed on an air cushion before being conveyed by blower via a rotary feeder into the silos.

Welding of the end products

During the subsequent intermediate storage, the blowing gas diffuses out of the pre-expanded polystyrene beads and air penetrates. This "packed air" is further processed in the converting process on an automatic moulding machine or in a block mould. To achieve low bulk densities, EPS can also be post-foamed in a second pass. For expandable polypropylene (EPP), EPP/HP pre-expanders are available for lightweight foaming.

Technical DataEPP Pre-Expander

Prozess Optimization

Bulk density control

Rotary feeder for material discharge into silo

Weighing device for starting material

Cover slotted screen for homogeneous temperature distribution

Exact pressure control +/- 0.1 bar

Options

Overfill protection for fluidized bed

Data storage

Automatic silo control

Weighing device for starting material

Exact pressure control +/- 0.1 bar

Accessories

Suction conveyor

Pressure loading tanks

Heating register

Cleaning function