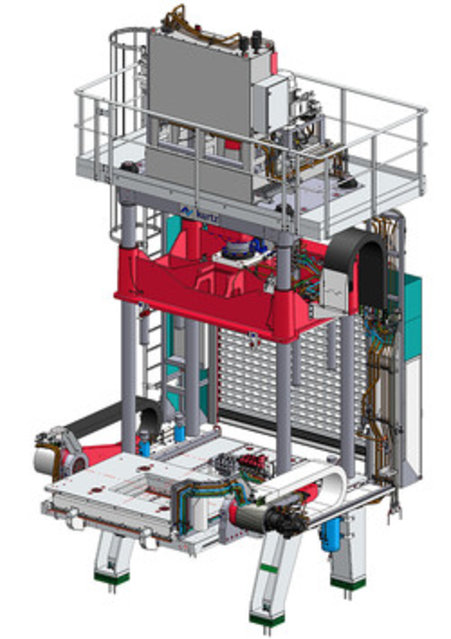

Even faster: Kurtz KPS 2000/25-12 SKT deburring press! Kurtz Casting Solutions

Kurtz has been manufacturing deburring presses since 2009, adding sliding tilt table presses in 2011. In 2014, Kurtz launched the KPS 2000/25-12 SKT deburring press-at that time, the largest and fastest system on the market. Until now, that is, because the latest press, unveiled for the first time at the in-house exhibition, sets new standards and is even faster!

Die casting has developed rapidly in recent years, making the deburring press in the cell increasingly important. Whereas in the past the die casting process was the determining factor for the possible cycle time, it is now the deburring process. To ensure that the press is no longer the "brake" of the cell, Kurtz is now launching this new development on the market. Compared to the presses built up to 2014, the new high-speed press is twice as fast, requires only half the cycle time, and outperforms all previous models from Kurtz and other manufacturers. Even though speed is becoming increasingly important, this was not the sole reason for the new development.

Optimized access to components and during maintenance

The accessibility of components for the operator and for maintenance work has been further improved. A highlight is the media cabinet, which is not only located outside the protective device, but also contains the pneumatic control and regulation components, as well as the optional central lubrication system and minimum quantity lubrication. The maintenance platform surrounds the hydraulic unit on three sides, making all fittings easily accessible for maintenance work. The new maintenance platform provides more space and freedom for tool changes, automation, and the addition of portals directly to the press.

The hydraulic concept has been fundamentally optimized, performance and speed increased, and energy consumption reduced. The press is equipped with a low-noise rotary drive with high torque, enabling tools to be rotated 180° in a maximum of six seconds - even with a tool base weighing up to eight tons! Up to four consumers/sliders can be controlled and driven simultaneously. This enables true parallel movements to be performed. Tool-free, fast, and safe changing of deburring tools is optionally available thanks to an automatic, safety-compliant clamping system. On request, all media (hydraulics, electrics, air, electrical signals) can also be connected via multi-couplings. This simplifies work and makes the system safer, as it prevents incorrect coupling.

User-friendly wizard tool change

The newly developed wizard simplifies tool changes - the operator is guided step by step through the change process via the visualization. The innovative, user-friendly, web-based software interface enables machine analyses for both process engineers and maintenance personnel. Using a server-client solution, multiple users can access the machine simultaneously, view data, and operate the machine via tablets or other devices. To ensure high availability of the Kurtz KPS 2000/25-12 SKT press, the "Condition Monitoring" option allows the condition of the press to be monitored at any time in order to detect possible downtimes or failures at an early stage and plan the resulting maintenance work. Numerous sensors and monitoring devices are attached to the process-relevant assemblies and components in order to call up the respective status of the component via software. Examples of this are leak detection, filter service life, pressure monitoring, and wear indicators on the tool.

With the new KPS 2000/25-12 SKT deburring press, we have achieved

the Kurtz developers have numerous goals, such as:

- Speed/cycle time

- Parallel movements

- Noise level/volume less than 72 dB(A)

- tool-free quick-change system for deburring tools, including automatic coupling of all media

- Condition Monitoring

- Consumption measurements

- highest energy efficiency thanks to speed-controlled motor-pump drives

- simplest maintenance

- intelligent machine control

- Wizard function for guided operator activities, e.g., tool change and maintenance

- central location for all consumables