Taking responsibility

Protecting our environment is a central task for us. We rely on sustainable production processes, efficient use of resources and innovative technologies to minimize our ecological footprint. For us, environmental awareness means taking responsibility - today for a world worth living in tomorrow.

If you would like to find out more about our path to becoming a more sustainable company, you will find further details below on our implemented and planned projects and activities, the targets we have set ourselves and the extent to which we have achieved them, as well as our key performance indicators.

Approach / Strategy

Energy consumption within the organization

Energy consumption within the organization

A central guiding principle in our business processes is to conserve natural resources. We therefore pay particular attention to reducing our energy consumption. At the same time, we are increasing our commitment to producing our own electricity and want to increase the proportion of renewable energy sources in our energy mix. In this way, we aim to reduce the environmental impact of production. Having already made visible progress at our German sites, we want to implement similar optimizations internationally.

Greenhouse gas emissions

Greenhouse gas emissions

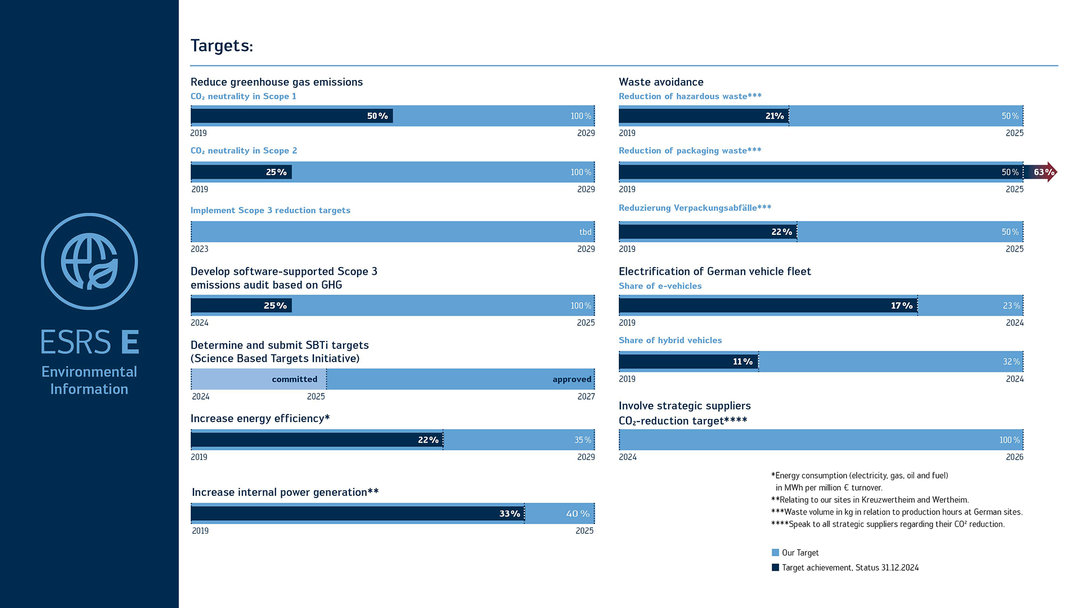

Our ambitious plan is to achieve CO2 neutrality across the Group by 2029 (in terms of Scope 1 and 2 as well as reported Scope 3 emissions). The complete switch to green electricity and biogas from renewable sources at the German sites will make a tangible contribution to this.

In order to reduce climate-damaging emissions, we are focusing primarily on saving energy, as this is where we can exert the greatest influence. Despite the recent fall in energy prices, this strategy is also of economic importance. This results in measures to measure, optimize and reduce energy consumption - and thus continuously reduce CO2 emissions through direct and indirect emissions.

When analyzing direct company emissions, we are guided by the Greenhouse Gas Protocol (GHG Protocol), which was developed as a tool for determining greenhouse gas emissions in companies. Since the beginning of 2025, we have been using a software solution to specifically record and evaluate other indirect greenhouse gas emissions (Scope 3).

ISO 14001 and ISO 50001 certifications

ISO 14001 and ISO 50001 certifications

The number of locations with ISO 14001 and ISO 50001 certification is continuously increasing, especially internationally. The two management systems (environmental management and energy management) are incorporated into our integrated management system (IMS), consisting of ISO 9001, ISO 14001, ISO 45001 and ISO 50001. By the end of 2024, a total of 9 out of 13 production, administration and logistics sites had been certified (8 in Germany, 1 in America), enabling us to integrate 79% of all international employees into our IMS.

Sustainable development

Sustainable development

As a globally active mechanical engineering company, we are part of a particularly energy- and resource-intensive industry. In order to include ethical, social and ecological aspects in the development of new product components, a sustainable analysis plays a central role (materiality of the topic). This includes the choice of raw materials and materials, their sources of supply, procurement and production processes through to delivery routes and the environmental impact during the operating phase.

In addition to the typical technical requirements, we therefore look at key sustainability data in this early phase of development, such as the subsequent consumption of operating resources and manufacturing efficiency. We also include questions of disposal and recycling at the end of the product´s useful life in our considerations. This means that development already plays a key role in the environmentally and socially responsible production and use of our goods.

Further information, in particular on current measures in this area, can be found in our sustainability reports.

Energy and greenhouse gas emissions

Self-generation of electricity with PV systems and CHP units

Self-generation of electricity with PV systems and CHP units

We were able to significantly improve our own electricity generation in the reporting years 2023 and 2024. This is largely due to the four photovoltaic systems that were connected to the grid in the course of 2023 (3 systems with a total output of around 1.5 MWp) and 2024 (1 system with a total output of 0.3 MWp).

We also want to commission further photovoltaic systems in the future so that we can achieve our self-imposed target of generating our own electricity.

E-charging points and electrification of our vehicle fleet

E-charging points and electrification of our vehicle fleet

Converting our vehicle fleet to electrically powered vehicles is one approach we are taking to reduce our fuel consumption. In 2023, Kurtz Ersa therefore significantly improved the infrastructure for the further conversion of the vehicle fleet to battery electric vehicles. A total of 70 charging points for electric vehicles were installed at our sites in Wertheim and Kreuzwertheim. The charging points are available to the company´s own fleet as well as the private vehicles of our employees and our business partners and are powered exclusively by electricity from renewable sources.

Green electricity and biogas

Green electricity and biogas

Since January 2023, we have been sourcing 100% of our electricity for all German locations from renewable sources (green electricity). At the beginning of 2024, we also switched our gas procurement completely to renewable generation (biogas). The possibility of generating or procuring renewable energy at our international locations is regularly reviewed, but has unfortunately not yet been implemented.

LED conversions

LED conversions

In the reporting years 2023 and 2024, we invested heavily in LED lighting, thereby significantly reducing our energy consumption for lighting. We have gradually replaced the light sources in several international plant and office buildings with significantly more efficient LEDs. Thanks to the intelligent lighting control of the LEDs, we also have the option of individually controlling certain areas and adjusting the brightness as well as automatically varying the lighting depending on the amount of daylight. We will continue to convert to energy-efficient LED lighting in the future.

Heating replacement

Heating replacement

We need almost half of our total energy consumption just to operate our heating systems in order to heat our buildings and provide hot water. Consumption can be significantly reduced by installing new and more efficient heating systems, ideally in conjunction with a heating control system. For this reason, we have already replaced three heating systems since 2019 and will continue to do so in the coming years.

Waste and water management

Waste

Waste

Dealing with waste plays a particularly important role in the sustainability considerations of manufacturing companies. On the one hand, waste cannot be avoided in the production process; on the other hand, dealing with waste recycling and avoidance has a significant impact on the sustainability balance because it can reduce material flows and conserve energy resources. In addition, waste represents an environmental risk because, for example, improper storage and disposal can release harmful and hazardous substances into the environment.

For Kurtz Ersa, it is a matter of course to ensure that waste is handled properly. This includes measures for disposal as well as for the recycling of raw materials that may be of importance again for production. However, we believe that the most effective strategy for minimizing environmental impact is to avoid waste.

Reduction of hazardous waste

Reduction of hazardous waste

As part of our efforts to make our production processes more sustainable, hazardous waste is always a particular focus due to its high environmental impact. At our sites worldwide, we only have a few sources of hazardous waste, such as two paint shops, several metalworking machines and small surface coating facilities. Our quantities of hazardous waste have decreased significantly, particularly since the dismantling of the electroplating plant was completed in 2022.

However, we are continuing to focus on the gradual replacement of hazardous operating materials with more harmless, ideally completely non-hazardous substances and are examining where this is possible (substitution of hazardous substances).

Water management

Water management

Sustainable water management is a key element of our operational environmental protection and encompasses several aspects. It is essential for us to reduce our use of water, including our supply chains, and to increase efficiency in its use. We take care not to exacerbate water scarcity and do not take surface water from lakes, rivers or wells, but are connected to the public drinking water supply everywhere. In this way, we protect water stress areas where water extraction is greater than the inflow. Our water management also includes waste water. We are connected to the public sewer system at all locations.

Rainwater utilization

Rainwater utilization

At a site in Kreuzwertheim, we installed a trench drain as part of construction work in the outdoor area. It is completely below ground level and consists of a rainwater retention basin with an integrated cistern. The cistern can store up to 70 cubic meters of rainwater, which we have been able to use to irrigate our outdoor areas since 2024. The installation of a cistern including a trench (underground rainwater retention basin) also has the advantage that the rainwater is only returned to the groundwater after a delay during heavy rainfall events, thus relieving the pressure on the sewer system.