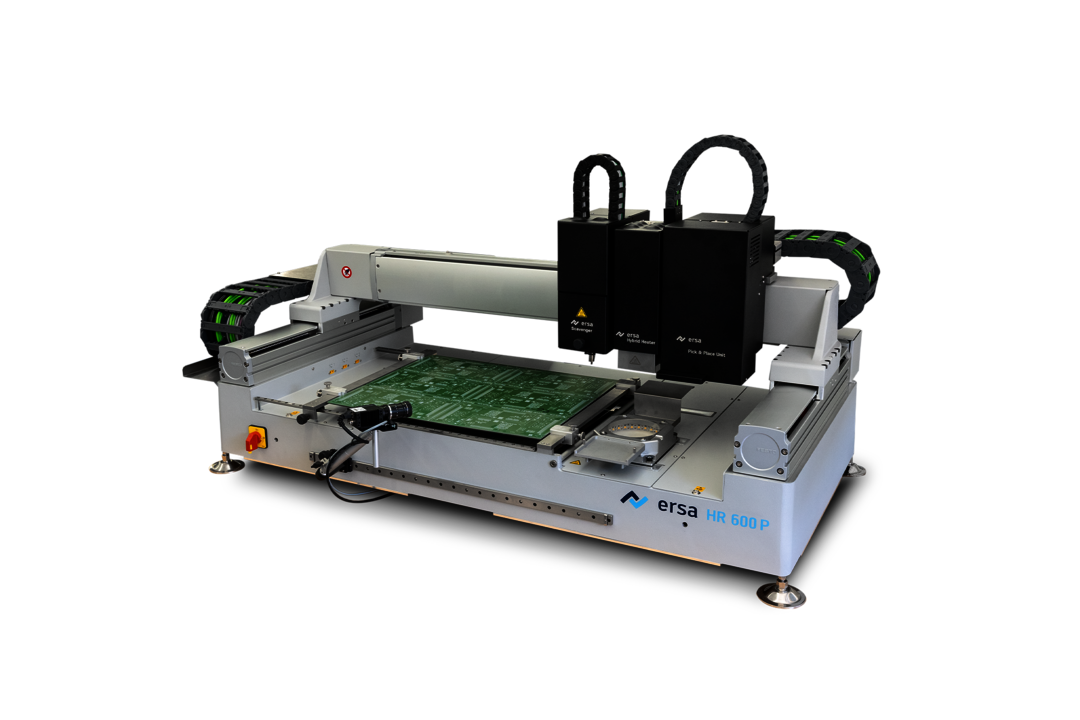

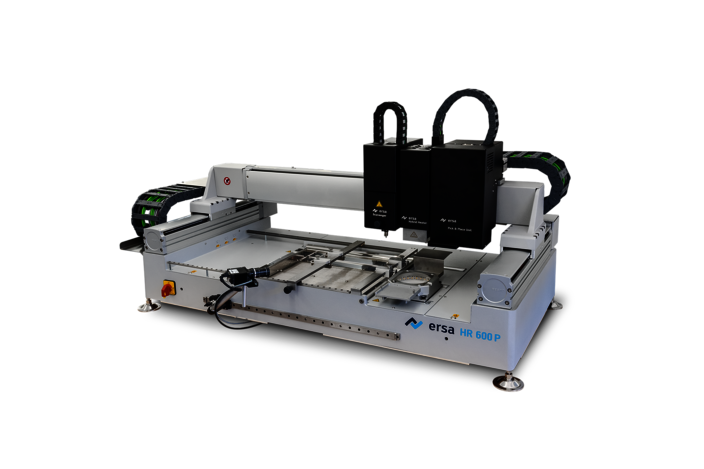

HR 600P - automatic rework system Ersa Rework

Automated rework precision for the best results

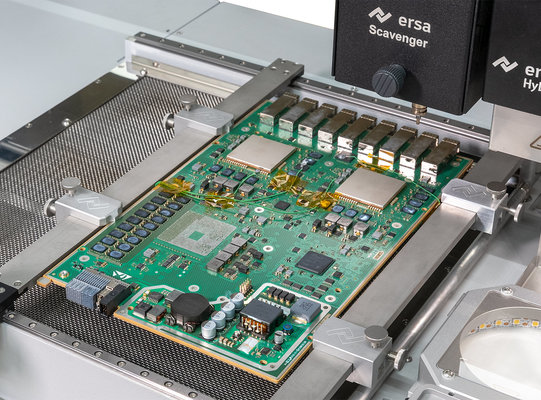

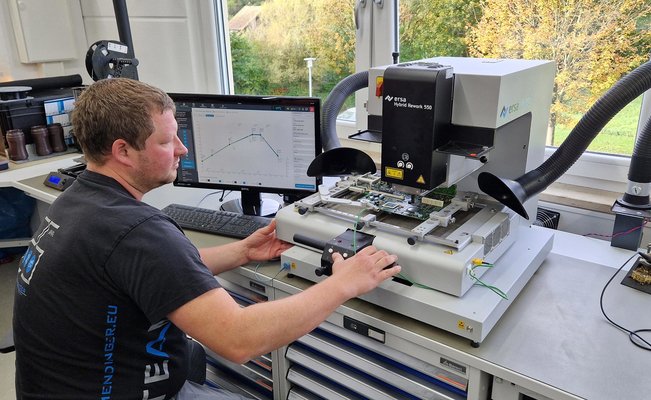

With the HR 600P, Ersa is taking the next technological step in the professionalization and automation of repairing electronic assemblies. The solid and highly accurate machine frame forms the basis for precise component placement and reliability.

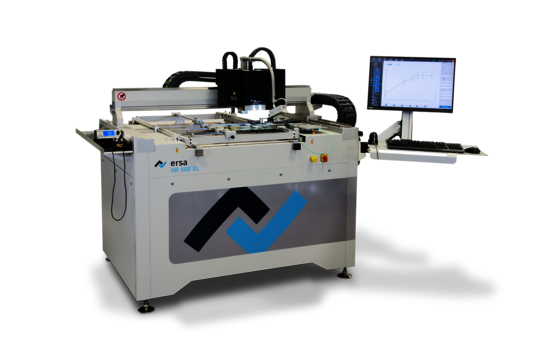

Ersa Rework Systems

HR 600 P: Smart component repair

Repairing instead of throwing away is doubly worthwhile - whether for large or small assemblies. Repairing assemblies with Ersa rework systems saves costs and helps the environment. Contact us and find out more!

Highlights HR 600PErsa Rework

- High-precision axis system, high-resolution cameras

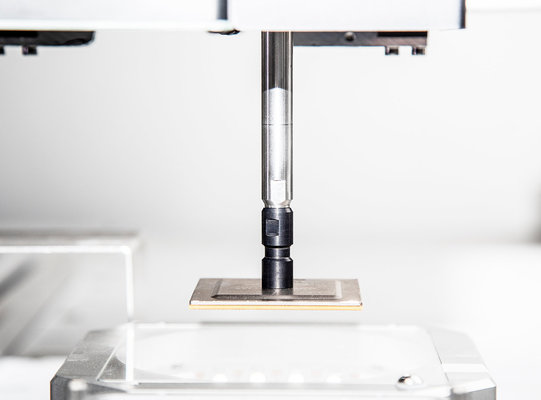

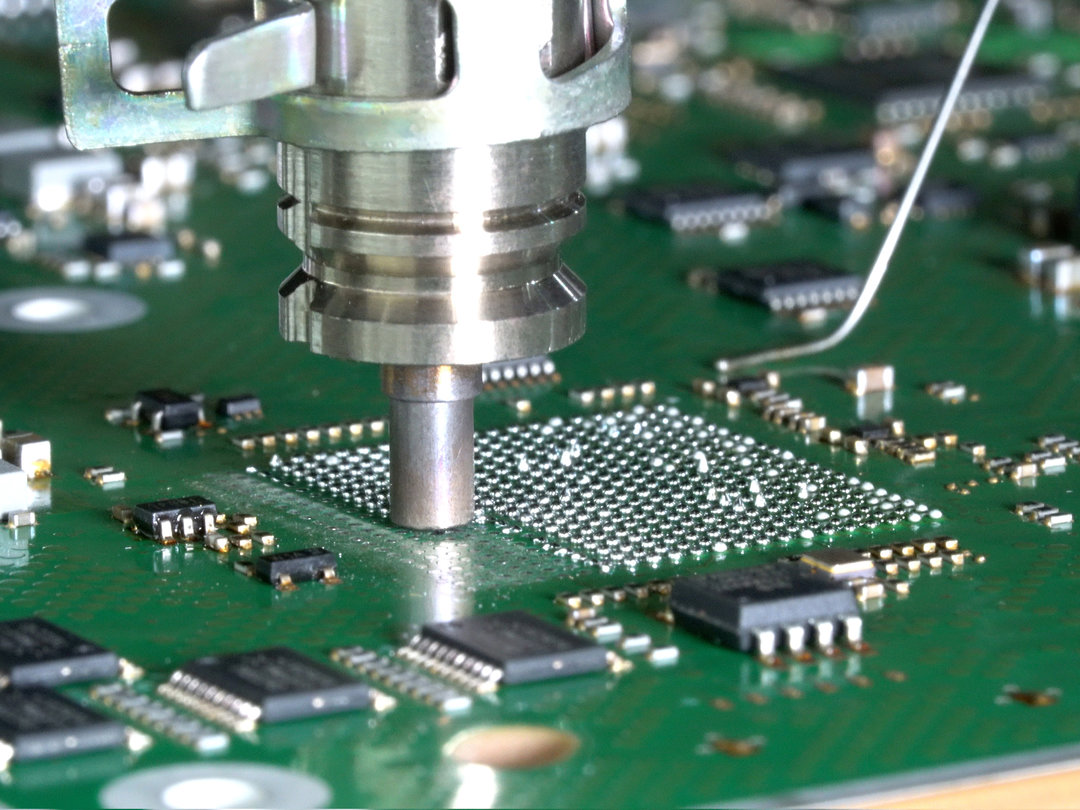

- Automated component placement as well as soldering and desoldering processes

- Hybrid heating head with two heating zones

- Process monitoring with reflow process camera

- Large-area, powerful IR underheating with three zones

- Three K-type thermocouple inputs for AccuTC sensor

- Effective component cooling with compressed air

- Optional residual solder removal with AUTO SCAVENGER (can also be retrofitted)

Maintaining added valueErsa Rework / HR 600P

The technology of Ersa rework systems ensures sustainable added value in electronics production:

- Gentle heating technology

- Sensor-guided soldering processes

- Contactless residual solder removal

- Precise component placement

- Complete process documentation

- Clear user guidance

Product FeaturesHR 600P

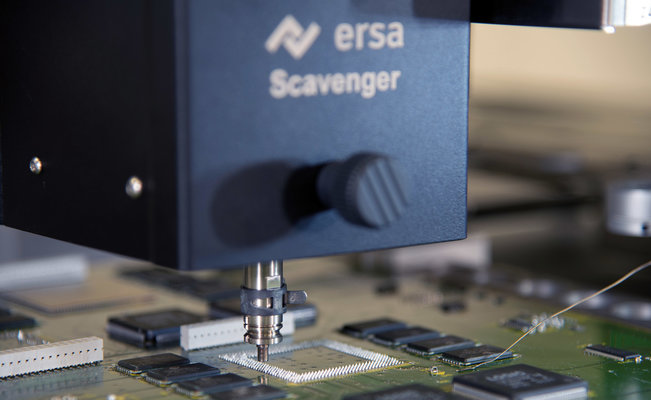

Automatic residual solder removal for HR 600PErsa Rework / Auto Scavenger

Before a new component can be soldered onto a circuit board, the solder remaining on the circuit board after desoldering must be removed. In an automated process, the Auto Scavenger SC 600 gently removes the remaining solder from the connection surfaces on the PCB. The module can also be retrofitted and is fully integrated into the HRSoft 2 software.