Flexibility is the key point for jobbing foundries besides quality and a reliable process. With every new investment, the first question is always the same: Which machine is “the right one”? Especially when it comes to small and medium-sized foundries that do not work for the mass market as automotive suppliers do. For a Turkish jobbing foundry, Kurtz was “by far the best choice” - statement of the customer -, offering the ideal machine and the perfect solution.

Highlights of the Kurtz AL13-13SC "2-in-1 solution" for molds and sand packs

- Crucible exchange furnace, from 300 kg to 1,500 kg capacity

- Use of 1 to 5 riser tubes via DOM System

- Manual on-site panel for teaching furnace filling level and pre-pressure determination

- Controlled or regulated water-cooling-system

- Controlled or regulated air-cooling-system

- Cooling circuits can be used as mixed circuits

- Blowing out the water circuits with air

- Machine axes via measuring systems, no mechanical adjustment of initiators as option

- Recipe management for machine and casting parameters

- Remote control for maintenance

- Parallel guidance

- Kurtz Ejector Systemm

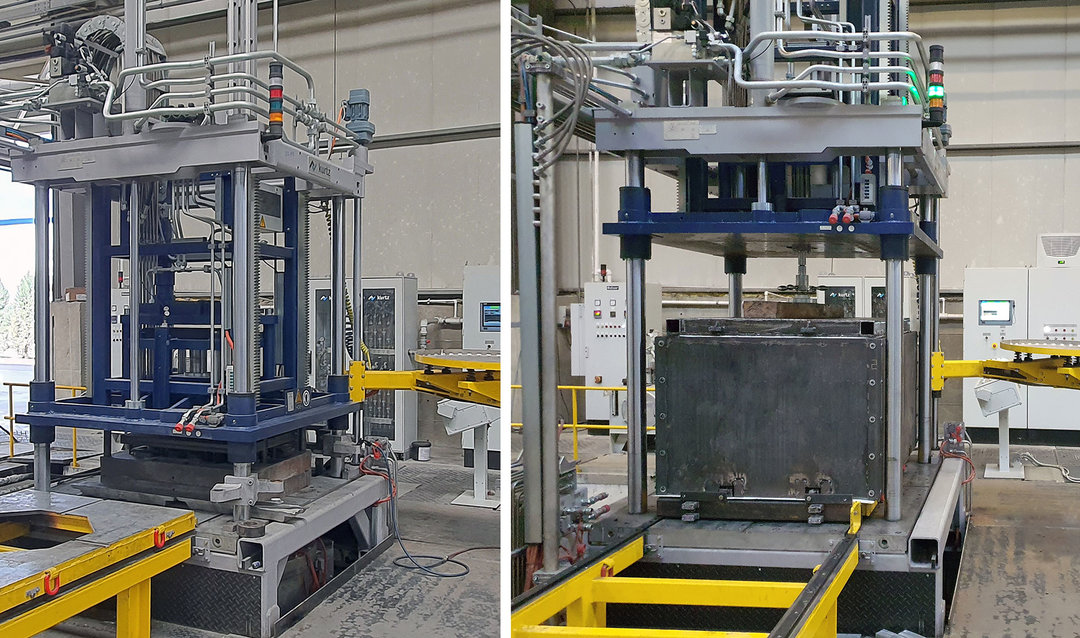

The “2 in 1 Solution” of Kurtz AL13-13SC fulfils the expectations for flexibility. Originally, this machine type was the classic low pressure die casting machine within the Kurtz portfolio. Based on the requirements of the Turkish market, Kurtz has further developed this machine type. Thanks to some additions, it is possible to cast complete core packages and sand molds besides permanent steel molds. In the case of sand molds, Kurtz is currently talking about sizes up to 1,250 mm x 1,500 mm x 1,500 mm, i.e. real large core packages.

Casting weight up to 700 kg

In addition to the mold size, the possible casting weight is important. Depending on the furnace, this can be 700 kg, as already realized by some of Kurtz’ customers in Turkey. A flexible gating system is no problem – from one to five riser tubes everything is possible. The standard Kurtz "DOM System”-Design (docked onto mold) means, that the riser tube can be docked directly onto the mold or sand package, which means less interfaces and far fewer temperature losses.

Flexibility and productivity are not a contradiction in terms. Both is realized with a crucible furnace changing system. The furnace is changed using a crane. Both the machine and the furnace are equipped with centering devices and multi-couplings so that they can be changed quickly. One furnace is in casting mode and the second furnace can be prepared for the next use in parallel which enables productivity in permanent mold casting through continuous casting. Neither time nor temperature is lost due to recharging. Another advantage of the furnace exchange concept is that jobbing foundries can use different alloys and divide them up into different furnaces.