The key to greater efficiency lies in the process. This is why Kurtz is expanding its portfolio and offering a new service in the form of on-site service visits as of Q3/2025 - a first taste of what the Moulding Machines will be presenting at K 2025 in Düsseldorf.

Information on the Kurtz Service Analysis Tool

As of October, Kurtz Service will provide you with information on process data acquisition, evaluation and system diagnostics. From Q4 we are happy to test your Kurtz machine individually - regardless of the year of manufacture. Simply send an e-mail to service-kurtz@kurtzersa.de

Complex processes in the production of molded parts made of particle foam or cast parts require in-depth know-how. Kurtz knows how to analyze and further develop these processes so that customers receive the highest quality and efficiency. This knowledge has been built up and continuously improved over decades at Kurtz Moulding Machines. From fall 2025, a new analysis tool will be available for all Kurtz machines. The aim is to make ongoing processes transparent and to optimize them in a targeted manner.

Making process and machine data visible

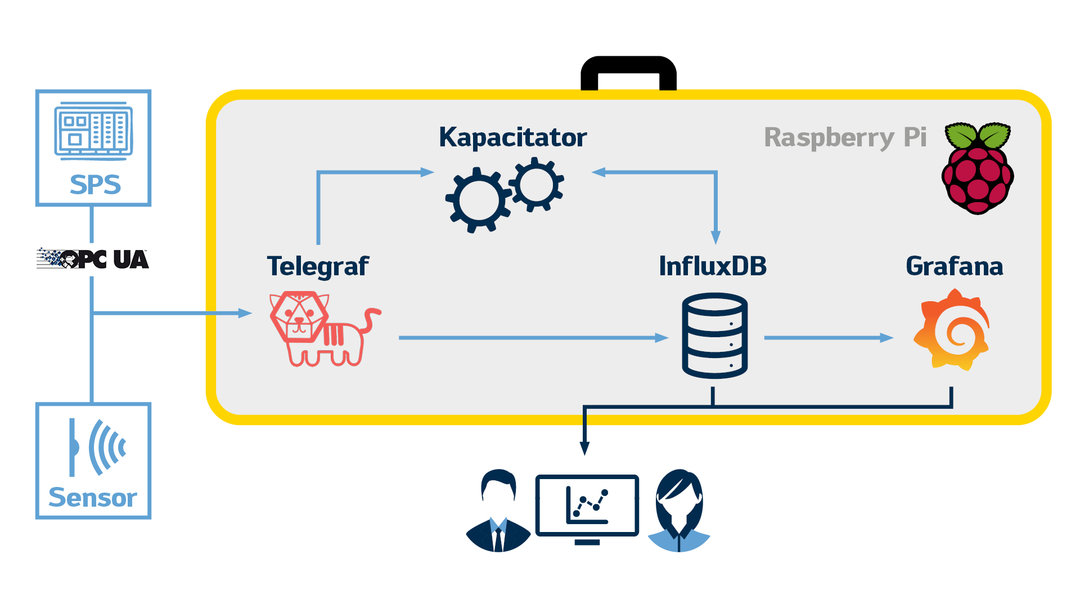

The new analysis service from Kurtz Service enables the professional recording and visualization of process and machine data directly on site, which was previously not available. A service technician records all relevant process and machine parameters – such as tightness or positioning accuracy – independently of the control system using compact hardware. A log documents the condition of the machine and shows any deviations or changes. The data is then analyzed by Kurtz experts and evaluated with the customer. The aim is to uncover potential for process improvements, e.g. through pressure adjustment or temperature monitoring. Sometimes it is even possible to open up new production possibilities with the existing system.