DIMER is a leading company in the processing of expanded polystyrene, polypropylene, and polyethylene. Since 1992, the Mexican company has maintained a trusting business relationship with our American location, Kurtz Ersa, Inc., not least with the Kurtz headquarters in Wiebelbach. A partnership that was tested in 2020 by external influences and has since become even closer. A success story that is anything but standard.

Decisive Moment

In the life of every company, there are moments that shape its character and determine its fate. For DIMER, this moment came in 2020 when a devastating fire in mid-December destroyed the plant in Reynosa. But as history teaches us, true strength is forged not in the comfort zone, but through adversity.

While the flames still smoldered and firefighters worked tirelessly, the DIMER team stood together amidst the rubble. In this decisive moment, a three-pronged plan was born: ensuring uninterrupted customer service, faster rebuilding, and securing financial recovery. This plan, simple in form but profound in execution, set DIMER on the path to restoring its pre-fire status and went even further.

DIMER immediately initiated measures to maintain operations. Outsourcing production just before Christmas, during the packaging industry´s busiest time of the year, was no small feat, but it allowed them to continue fulfilling customer orders and maintain customer loyalty. However, this required short-term financial sacrifices. At the same time, DIMER made the crucial decision to move to a new location that would allow for quicker setup and future scalability. Within a few months, our customer was back in operation – thanks to determined leadership, a dedicated team, and unwavering support from strategic partners like Kurtz.

Strong Alliances

Kurtz, with whom DIMER has worked since 1992, proved indispensable for the new beginning. The Kurtz team understood the needs of the packaging specialist, had confidence in the company´s future, and began production of new shape moulding machines immediately after DIMER committed to rebuilding. This commitment is an example of a cooperation that is rare in business – and even rarer in times of crisis.

The restructuring of DIMER did not end with the rebuilding. Determined never to experience such a vulnerability again, our partner heavily invested in fire prevention, safety protocols, and risk mitigation strategies. Today, DIMER is proud to hold certifications according to ISO 9001, ISO 14000, and ISO 45001. Additionally, a mutual aid agreement has been established with industry partners to ensure support in future emergencies. Thanks to such an agreement, intact tools will be provided to other packaging producers in the event of future fires or similarly caused production interruptions, allowing them to step in and continue production as subcontractors. This is especially important for maintaining customer relations.

Investments in People and Technology

After the fire, DIMER invested in its greatest asset: its employees. By strengthening the team in quality assurance, engineering, and advanced production management, it ensures that DIMER´s operational capabilities align with its strategic ambitions.

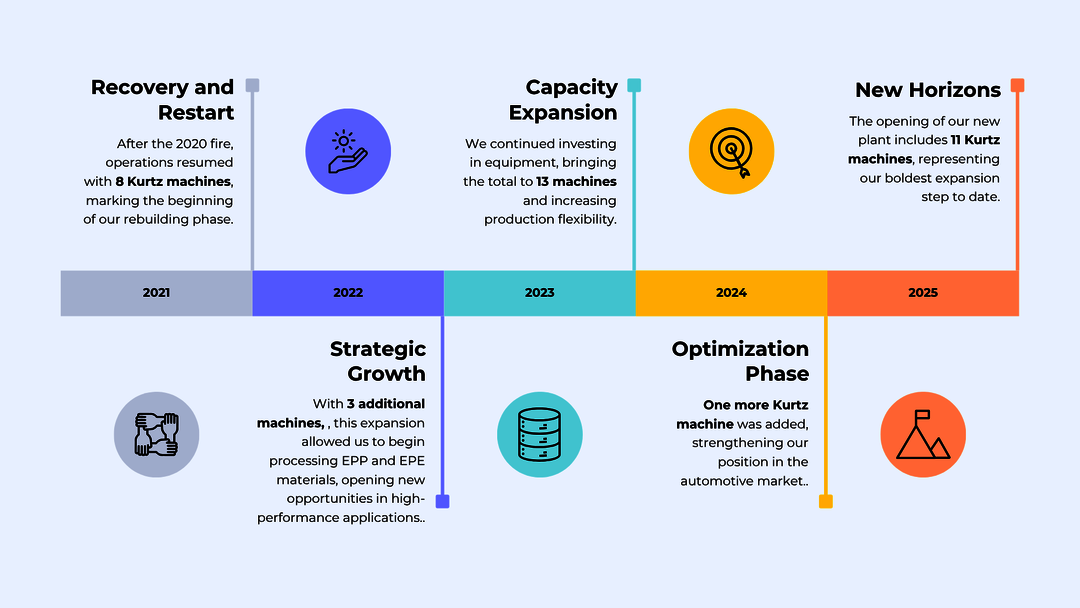

The infrastructure at DIMER has also grown exponentially. From an originally modest footprint with one factory and one distribution center, the Mexican packaging manufacturer now operates two production facilities – Reynosa and a new plant in Celaya, Bajío – and three distribution centers in Monterrey, Saltillo, and San Luis Potosí. Production capacities have expanded to 25 Kurtz shape moulding machines capable of processing EPS, EPE, and EPP with precision, flexibility, and at scale. This also includes state-of-the-art technology for producing EPP parts with insert components and their automation, such as production using the Kurtz ROTO FOAMER.

The centerpiece of the restructuring is UKKO, an internally developed MRP system for material requirements planning that integrates all areas of the operation – finance, production, maintenance, procurement, and more. Real-time monitoring provides detailed insights into resource consumption and machine performance. With ongoing AI integration, UKKO is more than just a tool; it is the digital nervous system of a company that aims to lead in efficiency, traceability, and innovation. This results in faster processes while also optimizing costs, offering additional value to customers.

The Path to the Future

The expansion to Bajío was just the beginning. Our partner is committed to disciplined, intelligent growth – initially at the national level, and over time also internationally. Every step is calculated and driven by customer-oriented demand and a long-term vision. The time since 2020 has taught the company that resilience, discipline, strategic clarity, and strong partnerships are the true architects of success.

The alliance with Kurtz is a constant source of strength, innovation, and resilience for DIMER in facing current challenges in the packaging market. We are DIMER´s strategic partner, providing reliable and forward-looking support through our competent team in sales and local service. Our group has the right technology mix that enables us to serve our customers excellently – just as we do for DIMER in producing packaging and moulded parts for the automotive sector. We can efficiently deploy EPS processing machines, such as those from the N-Line series, for mass production lines. With the A-Line series, which is manufactured in the USA for the North American continent, we offer a product for maximum flexibility and precision in particle foam processing. The Kurtz T-Line machines are high-tech machines that meet the highest automotive standards. Thus, all customer needs, from small to large series, can be met with the highest efficiency and quality standards. This is also what DIMER appreciates about Kurtz technologies.

DIMER´s success story is just beginning. The foundation for a promising future is laid, the vision is clear – and the opportunities ahead of DIMER are immense. We look forward to continuing to shape this future together with DIMER!