Company Technische Alternative expands production with Ersa HOTFLOW THREE User Report Technische Alternative

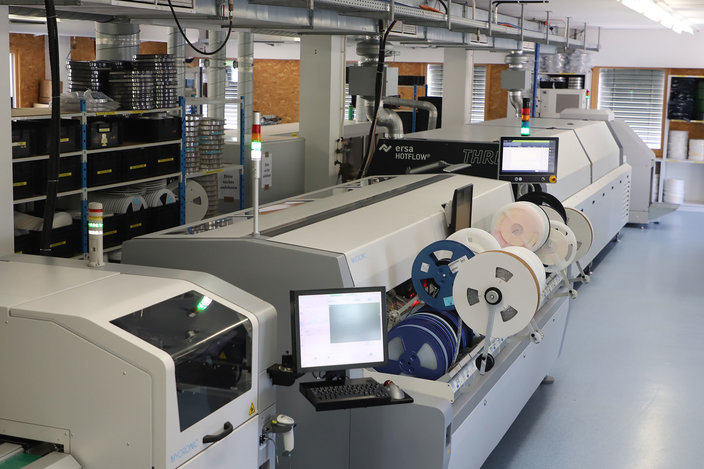

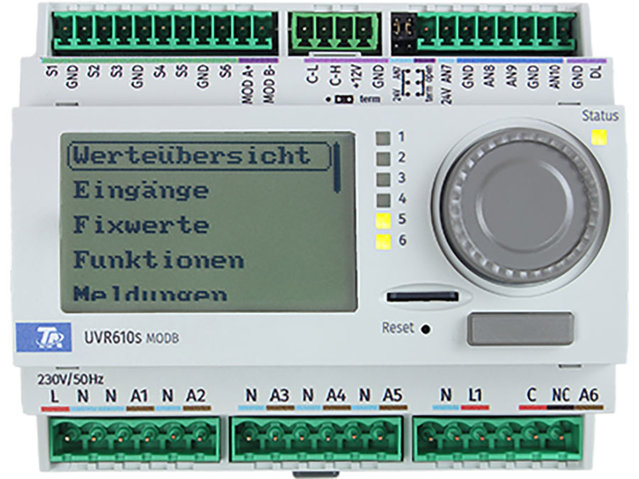

Technische Alternative RT GmbH started as a classic garage project by company founder engineer Kurt Fichtenbauer at the end of the 1980s. Together with a partner, the first solar controllers were manufactured entirely by hand - a milestone in terms of price-performance ratio. This was followed in 2003 by the universally applicable and easily programmable UVR1611 controller, whose drag & drop principle using PC software is still unrivaled today. An Ersa HOTFLOW THREE reflow soldering system has been part of the Lower Austrian company´s machine park since 2023.

As order volumes grew, the existing soldering technology at Technische Alternative reached its limits. A new reflow soldering system should not only enable higher throughputs, but also impress in daily handling. The decision was made in favor of the HOTFLOW THREE from Ersa - distributed by Stepan GmbH. Technische Alternative RT GmbH, based in Amaliendorf (Lower Austria), has been developing and producing innovative control devices for heating and building technology since 1989. The company employs 65 people, who work on a production area of 1,000 m². TA products are sold via the specialist trade and wholesalers and are installed in more than 40 countries worldwide - over one million systems are now in operation with the smart TA systems.

Production growth as a driver for technical innovation

“In recent years, the production volume in our electronics department has increased massively,” reports Wolfgang Buchsbaum, who has been with the company for 25 years and is responsible for electronics production. “Our existing vapor phase system was increasingly reaching its capacity limits. The cycle time window was simply no longer sufficient.” A new system was needed - more powerful, future-proof and efficient in operation. The company had already started building its own SMD line in 2010, supported from the beginning by Stepan GmbH from Vienna. It was clear that the company would once again rely on its proven partners for the upcoming renewal of the soldering technology - assuming successful benchmarking.

Decision after live demonstration

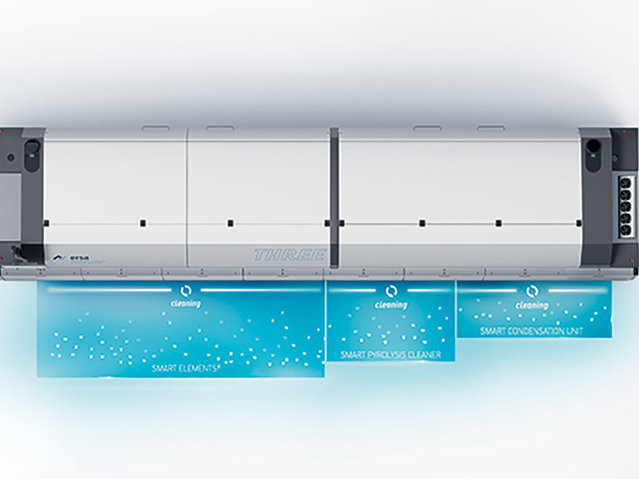

After market research and initial discussions, three reflow systems were selected for the shortlist. The people responsible for the Technical Alternative traveled to Hamburg, were in Carinthia and finally at Ersa GmbH in Wertheim am Main, where their own TA products could be soldered under real conditions. “With Ersa as a leading supplier for electronics production and Stepan GmbH as a long-standing partner, the decision was very easy for us,” says Wolfgang Buchsbaum. The choice fell on the HOTFLOW THREE, a modern reflow soldering system with a maintenance-friendly design and high flexibility. The reflow system from Ersa impresses in terms of performance as well as service - twelve or more weeks of non-stop operation without maintenance intervals speak for themselves. In terms of quality, the HOTFLOW THREE convinces across the board thanks to its SMART CONVECTION POWER UNIT (SCPU®) - the exclusively developed motor and control unit ensures optimized soldering profiles and therefore even better soldering quality.

Easy integration into electronics production

Despite its size, the new system was easy to integrate - first a forklift was used to unload it from the truck, then a trolley. Appropriate space was created in advance in the production area itself - after just three days, the HOTFLOW THREE was fully operational with a combined effort. “We were impressed by the soldering quality right from the first tests in the demo room - and this continued seamlessly in series production,” remembers Wolfgang Buchsbaum.

TA manufactures around 150 different products in varying quantities. Frequent product changes are part of everyday life - on average, retooling takes place every one to two days. Thanks to the well thought-out software structure and clear user interface of the HOTFLOW THREE, the retrofit is completed within 15 to 20 minutes - this was one of several important aspects for TA when making the selection. Another advantage: Despite very good results with nitrogen, it was possible to avoid its use, which saves both energy and costs. “Even with the first soldering profile, we achieved very good soldering results right from the beginning - without solder balls, without defective solder joints,” praises Wolfgang Buchsbaum.

Focus on maintenance and future-proofing

For the HOTFLOW THREE, Technische Alternative deliberately chose the most extensive cleaning and maintenance equipment and therefore the highest configuration level. The aim was to reduce the maintenance intervals to a minimum. “Since then, we have been working in 1-shift operation with just one maintenance operation per year - that meets our requirements exactly.” At the same time, a second shift is already being considered - a good sign for further growth.

TA is also already looking to the future, as the existing wave soldering system has now been in use for around 20 years. Initial considerations for a replacement have already been made - again with the aim of keeping productivity and energy efficiency up to date. With the HOTFLOW THREE from Ersa, Technische Alternative has taken an important step towards future-proof, high-performance electronics production. The combination of ease of maintenance, process reliability and fast retrofitting is ideally suited to Technische Alternative´s varied day-to-day production and will continue to positively support the company´s future development.

Categories

Our contact

Rainer Krauss

Overall Sales Manager