Continue wave soldering or switch to selective soldering? User Report

After a successful test phase, VERSAFLOW ONE replaces the wave at VOIGT electronic

Having started out in the bathroom and bedroom of the family home almost 35 years ago, VOIGT electronic is now a modern EMS service provider with great passion and expertise in electronics manufacturing. The product spectrum ranges from components for biogas plants to medical technology. With the VERSAFLOW ONE from Ersa introduced in 2021, THT production has now been modernized and additional capacities created.

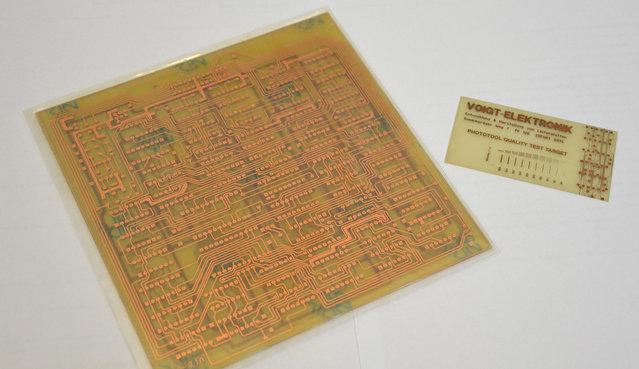

April Fool's Day? No - the founding of VOIGT electronic GmbH on April 1, 1989 was not an April Fool's joke, but the start of a success story more familiar from the USA. The origins of this story lie in the former GDR - in Erfurt to be precise. After a nine-month marathon with the authorities, Matthias Voigt finally got his business license and started his company to manufacture printed circuit boards. From its beginnings in the living rooms of his parents' house with home-made production equipment - a converted hanging filing cabinet was used to expose the photoresist for the printed circuit board, for example - VOIGT electronic developed into a modern EMS service provider that is passionate about electronics. The company has never specialized in one sector, but is still broadly positioned today. The family-owned company manufactures components for measuring devices, communication and industrial electronics - as well as for railroad and transportation technology, which is used worldwide. The secret of success: VOIGT lives electronics. We put ourselves in the shoes of our customers and their products in order to understand them and manufacture them optimally. If necessary, products are optimized in close cooperation with the customer and quality is ensured. With the advent of SMD technology in the 1980s, developments in electronics have changed rapidly. Mixed assembly with THT components and SMD assembly on both sides is steadily increasing and is state of the art. The classic soldering process for plugged-in components is the wave process.

Wanted: More flexibility for new customer projects

However, VOIGT has now reached certain limits with this process. The portfolio does include products that are well suited to wave soldering, such as assemblies with a large proportion of THT on four-layer PCBs. These are mainly long-running products that have been manufactured for many years. However, many new customer projects are no longer good wave soldering projects - here we are dealing with assemblies for measurement technology or test systems, consisting of multilayers with up to 16 or 18 layers with a large component variance in bottom-terminated assembly. This means that all connections are on the underside of the board. The Erfurt-based company also has many small orders in its order book: in addition to series of up to 1,000 units, it also produces prototypes and batch sizes of 20 to 25 assemblies per series. Up to twelve product changes per day have to be managed. VOIGT therefore launched a project to evaluate and replace the existing wave soldering system. This also involved evaluating whether the wave soldering process was still suitable for the product range or whether it could be replaced by a selective soldering process.

The advantages of the selective soldering process include the elimination of solder masks, which protect SMD components on the underside of the PCB from being melted and washed away in the solder wave during wave soldering. They are also required for very small series. They have to be specially made for each product and are of course a time and cost factor. It is a constant balancing act - if too few masks are ordered, waiting times occur because they are not cleaned and ready for use again quickly enough after a soldering process. You also don't want to have too many masks for cost reasons.

Another advantage is the flexibility of the selective soldering process: the individual components of a PCB can be soldered with individual parameters, whereas with wave soldering you are forced to make compromises. Heating and wetting time in the solder wave can only be set for the entire assembly. The aim here is to find the best average value in order to protect sensitive components and still achieve sufficient wetting of the component connections with high heat requirements so that a reliable solder joint is created. As the selective soldering process also means that the PCB is only wetted with flux and solder at the points to be soldered, there is less residue on the PCB. This significantly reduces the amount of cleaning required and has a positive effect on cost-effectiveness.

The respective advantages of wave and selective soldering processes are to be found in the proportion of THT components in the assemblies to be processed. For assemblies with mixed SMT and THT placement, the classic wave soldering system has an advantage if the SMT placement is exclusively on the top side of the assembly. In this case, the wave soldering process is very economical, as no solder masks are required for processing. If, on the other hand, the underside of the assembly is also fitted with SMDs, with a low proportion of THT components, selective soldering has an advantage, as the cost-effectiveness is significantly higher simply due to the elimination of solder masks. "Of course, quality is crucial. But in this case, output was almost more important to us. At the end of the day, I have to have produced a certain number of assemblies, otherwise I won't be able to meet my delivery times," says Production Manager Frank Koppetsch, describing the requirements. "We are also currently experiencing a growth spurt," adds Managing Director Sabine Voigt. “The new system should make our production future-proof and provide a buffer for further growth.”

Technologically equipped for the future

VOIGT electronic has been operating an ECOSELECT 4 from Ersa for three years. It was therefore a logical step to contact the Wertheim-based soldering specialist again for the new production system. "We attach great importance to long-term partnerships. On the supplier side, this means that we need partners who not only supply the equipment, but also take us along technologically in order to be equipped for the future. That's what we get with Ersa," says company founder Matthias Voigt. This machine project was a classic win-win situation for VOIGT electronic and Ersa: the VERSAFLOW ONE was launched onto the market at Productronica 2021. This compact selective soldering system is Ersa's new entry-level model for high-end selective soldering. VOIGT electronic became one of the beta testers for the VERSAFLOW ONE. This gave VOIGT the opportunity to evaluate the process for the upcoming investment not only on the basis of a test assembly, but to send entire production series through the machine. Under real conditions, the company was able to find out whether the existing wave could really be replaced by a selective soldering system.

Four equipment variants are available for the VERSAFLOW ONE. Thanks to these fixed configurations, the VERSAFLOW ONE can be delivered in just two to four weeks. The core processes of fluxing - heating - soldering have been adopted from the premium models VERSAFLOW 3/45 and VERSAFLOW 4/55. This means that the VERSAFLOW ONE also features solder level monitoring with automatic solder wire feed, solder wave height monitoring and regular automatic nozzle activation. This also includes the three-part pin chain transport with 3 mm edge support and automatic width adjustment, which can be quickly adapted to different PCB formats. The soldering module is available with one or two solder pots - a special feature here is the x-variability. In the maximum expansion stage, the system has two soldering modules. The VERSAFLOW ONE also achieves energy savings of 10% in the preheating stage. The glass cover has been replaced by a grid through which the heat reaches the assemblies directly without absorption loss. By changing the distance, the number of IR emitters could be reduced and the performance of the heater maintained.

Intuitive operation with ERSASOFT 5

“Our team got to grips with the system extremely quickly,” reports production manager Koppetsch on his experience with the system. All Ersa selective soldering systems have a similar operating concept, which is extremely intuitive and user-friendly. VOIGT also benefited from the previous knowledge gained from operating the existing ECOSELECT 4, because like all Ersa systems, the VERSAFLOW ONE is also controlled using the ERSASOFT 5 operating software. The integrated CAD-Assistant 4 editor makes creating soldering programs quick and easy. Of course, the programs for a product can also be saved and are therefore quickly available when required. Both features are extremely important in companies with frequent product changes.

The soldering quality and throughput of the VERSAFLOW ONE were convincing, as were its ease of maintenance and low nitrogen consumption. “From our point of view, you need a nitrogen tunnel to operate a wave system properly,” explains Frank Koppetsch. “As we generate our own nitrogen, we would have had to invest in a larger system for a wave. To cover the soldering bath in the VERSAFLOW ONE with nitrogen, the consumption is only 2 m3/h. We can cover this very well with our nitrogen generator.” VOIGT electronic therefore decided to take over the VERSAFLOW ONE as a replacement for the wave soldering system after the test phase. “We are now even more flexible in production and have the desired capacity buffer. Maintenance is much easier and faster than with our old wave soldering system. We are now in an excellent position for the future in this area, especially as our ECOSELECT 4 can be upgraded to a VERSAFLOW system if required,” summarizes Frank Koppetsch.