Designed for innovation – AL 28-18-18 FSC low-pressure casting machine Kurtz Casting Solutions

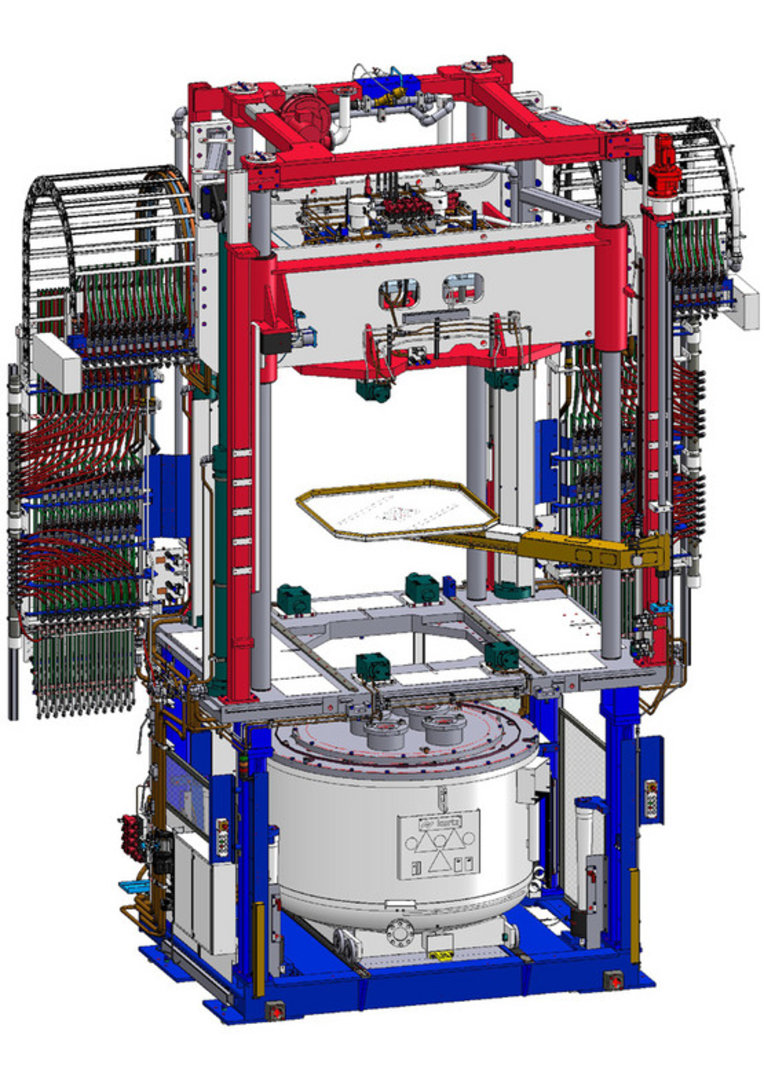

The new AL 28-18-18 FSC expands the Kurtz low-pressure casting machine portfolio with even more clamping surface and hydraulic power. The AL 28-18-18 FSC relies on proven Kurtz low-pressure casting technology to achieve even greater benefits for the user with numerous newly optimized assemblies and components. The objectives of the new development, in addition to those of the deburring press, are innovative and economical casting, lower overall height, a tool-free quick-change system for molds, including coupling systems for mold cooling, the option of tilting the movable clamping plate for better accessibility, for example during finishing, and higher ripping, closing, and ejection forces.

Tool format 2,800 x 2,000 mm (WxD)

Thanks to the innovative trapezoidal arrangement of the guide columns, tool formats with a maximum width of 2,800 mm and a depth of 2,000 mm can be clamped. The optional hydraulic clamping system allows molds to be set up more quickly and without the need for additional tools. A stroke of 1,800 mm with a clear width of 2,600 mm at the clamping unit allows components to be easily removed using the attached removal unit and also offers excellent conditions for automation using robots. The milestone and highlight is undoubtedly the mold split detection function, which prevents aluminum from leaking when the mold is not completely closed and avoids production downtime. The redesigned furnace changer makes furnace changes even faster. Flat-parallel docking of the furnace to the mold allows the use of multiple riser systems on a very large pitch circle without any problems. Up to twelve risers have been used in practice to date, and technologically speaking, this is certainly not the end. Low-pressure furnaces with a filling volume of up to 3,000 kg are the preferred standard for series production at Kurtz.

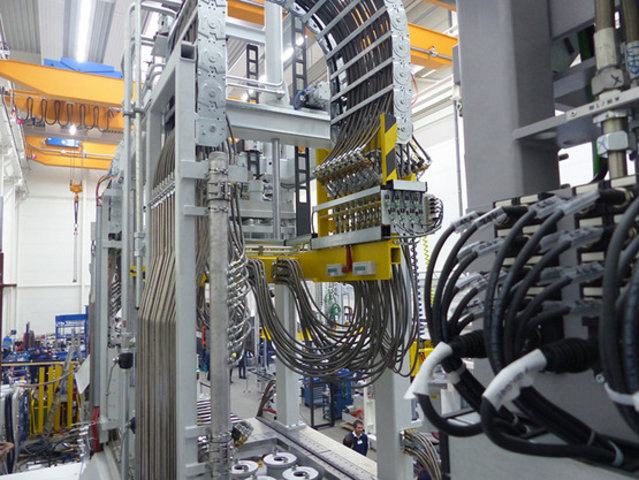

The completely new hydraulic system of the AL 28-18-18 FSC enables faster travel speeds with greater forces. This system also achieves higher clamping forces during casting, with demolding forces of up to 100 tons. The low-noise hydraulic pumps can be switched on individually to achieve the necessary pressures and flow rates - with increased energy efficiency.

Up to eight additional ejector cylinders, which can be flexibly positioned on the movable clamping plate, support the central ejector cylinder with up to twelve additional punches to enable the reliable ejection of components at all times for large-area castings or structural parts and to prevent or minimize component distortion. Optionally, the central ejector cylinder can also be automatically connected to the ejector plate of the mold. The operator is supported by the newly developed wizard, which guides them step by step through the mold change process.

Special feature:

maximum machine availability

The cooling system of the AL 28-18-18 FSC has 96 mixing circuits that can be connected to the mold using smooth-running multi-couplings. An expansion to 128 mixing circuits is possible. The newly designed, web-based software interface makes it much easier to enter the cooling parameters for individual cooling circuits, and the new user-friendly visualization offers the user the best possible convenience in their daily work. Using the new server-client solution, multiple users can access the machine at the same time, view data, and operate the machines via tablets or other devices. To ensure high availability of the Kurtz AL 28-18-18 FSC casting machine, the "Condition Monitoring" option can be used to monitor the condition of the casting machine at any time in order to detect possible downtime or failures at an early stage and plan the resulting maintenance work.

Sensors and monitoring devices enable the machine status to be displayed, which can be accessed at any time via software. Some examples of this include: display of energy consumption, leak detection, filter service life, pressure monitoring, and wear indicators on spindles and guides. Kurtz is perfectly equipped for the future of low-pressure casting - are you?