BVS Electronics relies on Ersa rework technology

Reliability, quality, and availability – these are the three pillars on which the success model of BVS Industrie-Elektronik GmbH from Hanau is based. As one of the leading service providers for manufacturer-independent maintenance of CNC, PLC, and robot automation technology, the medium-sized company also sets the highest standards in the field of rework – and has been relying on solutions from system supplier Ersa for over ten years.

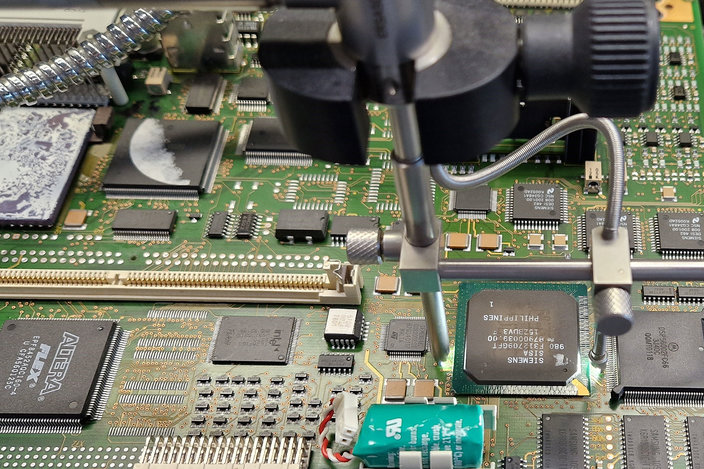

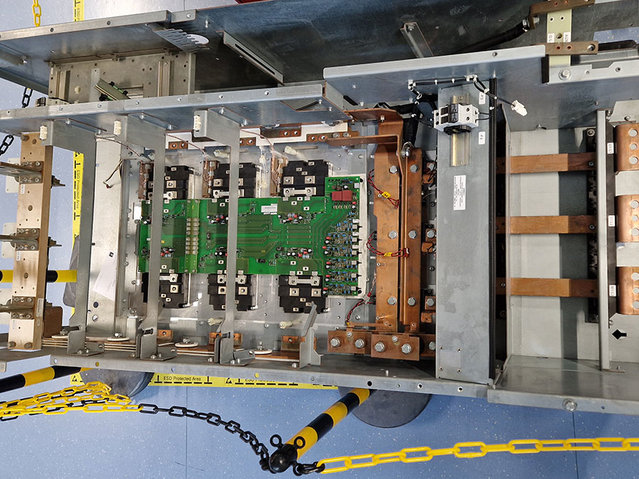

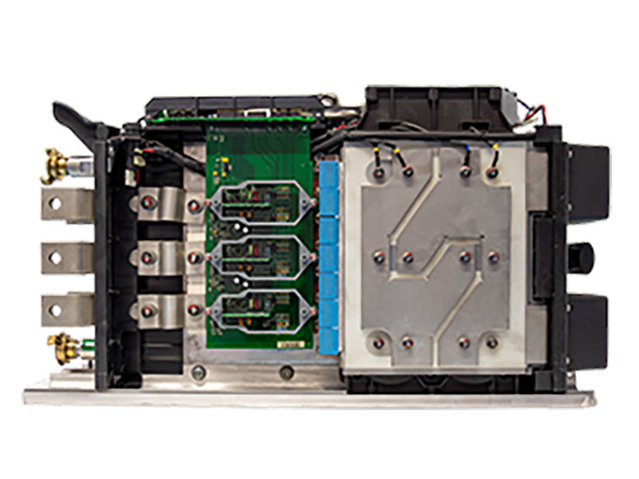

Since 1987, BVS Electronics has been a major player when it comes to repair, sales, and service for CNC, PLC, and robot automation technology and electronics for renewable energies. This applies not only to current series and assemblies, but also to those that have long been discontinued or removed from production. The Hanau-based company consistently works in accordance with the requirements of the quality standards and quality guidelines of DIN EN ISO 9001:2015 and the environmental management standard DIN EN ISO 14001:2015. The quality management of the Hessen-based company is well received – its customer base now includes over 10,000 satisfied companies from all industries and of all sizes. Whether current systems or long-discontinued assemblies, BVS specializes in product overhaul repairs. And it does so with a claim that goes beyond mere troubleshooting: “For us, repair always means a complete product overhaul – at the highest level and with a 24-month warranty. In our certified repair process, assemblies are repaired exclusively based on manufacturer specifications and using new and approved components. Upon receipt, the assembly undergoes professional cleaning, including in an ultrasonic tank and an industrial washing system. As part of the product overhaul, defective components are replaced, and those subject to aging or higher wear are also replaced as a preventive measure. After successful repair, all assemblies are fully tested for functionality and under load on the manufacturer´s original test and load test benches,” says Thorsten Ruth, Department Manager at BVS Electronics.

Fully automated, process-reliable assembly repair

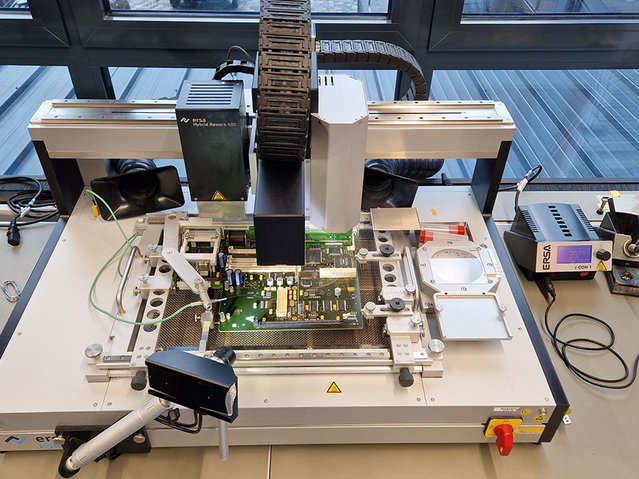

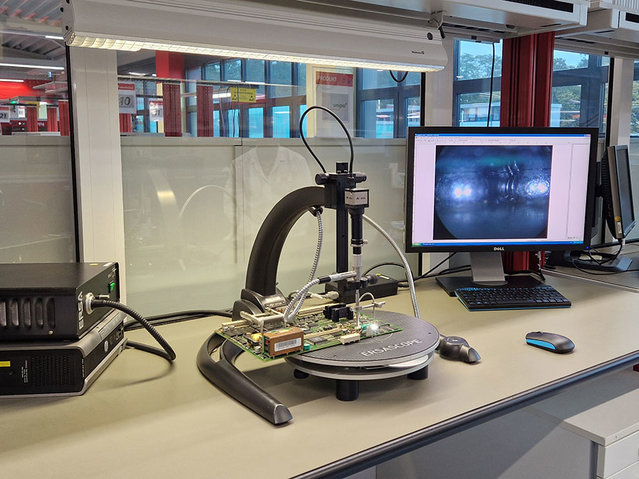

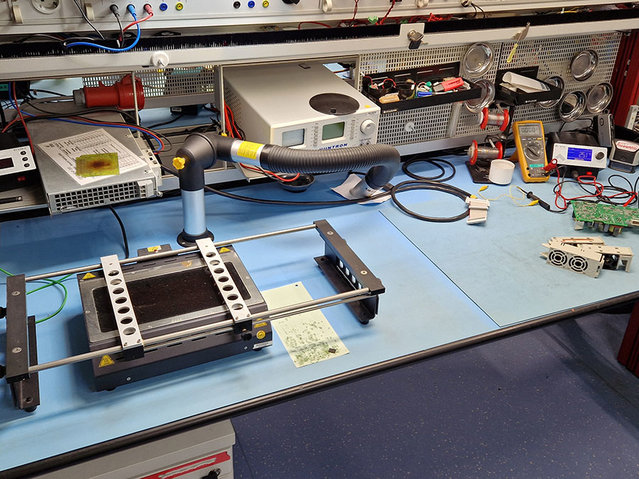

Process reliability is essential. Since 2012, BVS Electronics has been working with system supplier Ersa to achieve this. At the beginning of the collaboration, an ERSASCOPE 1 inspection system was installed, which can be used to inspect BGAs, CSPs, flip chips, wetting angles, THT feedthroughs, and other concealed solder joints. Four years later, the HR 600/2 was introduced as the first Ersa rework system. Since then, it has been updated at regular intervals in terms of software and hardware, and BVS users have received specific training for it. Regular maintenance of the system and user training have since become standard practice at the company. With the HR 600/2, BVS has a solution that automates repairs of even high-pin-count components on modern assemblies and enables them to be carried out reliably. From precise placement and controlled lifting to defined soldering, the entire process can be automated and delivers reproducible results. “With the HR 600/2, we can carry out highly complex rework tasks reliably and efficiently – a real benefit for our daily work,” confirms Thorsten Ruth. Precise and careful handling is paramount, especially when dealing with sensitive or bonded BGAs, which are not uncommon in long-lasting industrial applications. For particularly demanding assemblies, BVS also works closely with recognized specialists.

“From the very beginning, BVS has been a highly professional partner with the highest standards of quality and technology. Our systems are in good hands there – and are used with great expertise,” emphasizes Ralf Walk, the Ersa Area Sales Manager responsible for Tools, Rework & Inspection. The demands placed on repair service providers are more diverse than ever before. At BVS, over 1,000,000 replacement and spare assemblies are available around the clock – the 24/7 emergency service ensures 365 days a year that production downtime on the customer side can be mitigated as quickly as possible. Every BVS employee is always aware that availability and speed are essential in the event of a production stoppage due to failure. BVS also remains true to its high quality standards when developing new business areas, such as maritime electronics and aviation. “Our motto ‘Quality makes the difference’ is much more than just marketing jargon – it is the standard by which we measure ourselves every day,” says Florian Bätz, one of the two Managing Directors at BVS Electronics. Strong partners such as Ersa help us achieve this by laying the foundation for consistently high repair quality with reliable, powerful technology and competent support. This has been the case for the last 13 years – and will most likely continue to be so in the future ...

Categories

Our Contact

Ralf Walk

Area Sales Manager