MTL Montagetechnik Larem GmbH relies on Ersa VERSAFLOW ONE X Selective soldering on an XXL scale

MTL Montagetechnik Larem GmbH is a medium-sized, family-owned company headquartered in Thuringia, Germany. At its Mühlhausen location, the team develops and manufactures industrial solutions. For example, MTL operates as an EMS provider for electronics and is a supplier of precision-engineering fixtures. MTL merges electronics with precision engineering to create unique solutions and recently added an Ersa VERSAFLOW ONE X to its equipment lineup in Thuringia.

The first contact between MTL and Ersa dates to Productronica 2023, when MTL was already considering a move into selective soldering. Customers and prospective clients were increasingly asking for PCBs in sizes that MTL´s existing equipment simply could not handle. This strengthened the company´s determination to expand its technology portfolio as well as to use a higher level of automation to help counter the shortage of skilled workers which is also felt in Thuringia. While looking for the right solution, the MTL decision-makers intensified discussions with system supplier Ersa, and it quickly became clear that the two companies were an excellent match.

MTL Montagetechnik Larem GmbH currently employs around 50 people and produces about one million assemblies a year, primarily in small- to medium-sized batches. With annual sales of approximately 7 mio. Euro in 2023, MTL is a popular partner for industries such as automation, building services, engineering, medical technology, and sensor systems. The company´s expertise is in high demand, especially for infrastructure projects.

Ewald Larem, who had previously worked in the automotive industry, founded MTL in 1995. The company started its electronics division with SMD assembly and has since evolved in several directions. Two major expansion phases, in 2000 and 2008, significantly increased the production area to 1,800 m², including an adjacent warehouse. Recently, new placement machines were added, enabling the SMT lines to run in line and process board sizes up to 508 × 600 mm. The new VERSAFLOW ONE X perfectly fits into this setup. “It allows us to enter the power electronics market, enabling us to manufacture particularly large and thick PCBs,” says Managing Director Fabian Larem. “That sets us apart from other EMS providers who can´t match our capabilities in either SMD or THT. Combined with our mechanical expertise, we are a highly productive partner for our customers that are happy to rely on us again and again.” At MTL, the VERSAFLOW ONE X has also helped reduce time-consuming manual soldering on standard products – making it possible to produce consistent, repeatable THT solder joints even on double-sided assemblies.

A compelling package: VERSAFLOW ONE X

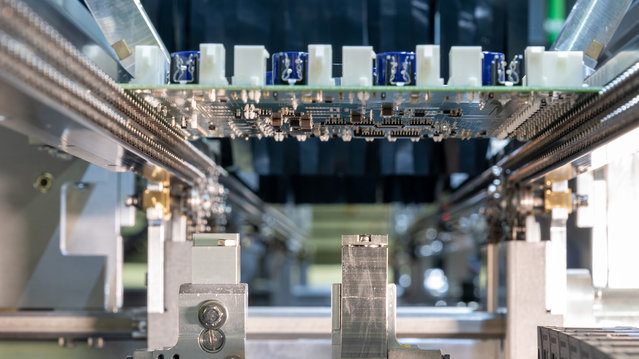

After an extensive market assessment, MTL selected the VERSAFLOW ONE X because it meets all of the company´s requirements. Designed as the entry-level model in the VERSAFLOW product family, the machine combines proven VERSAFLOW technology and incorporates the ERSASOFT 5 software for soldering program creation. Despite its compact dimensions (L × W × H: 4,430 × 1,791 × 1,577 mm), the system delivers the performance MTL needs.

The VERSAFLOW ONE X can be equipped with two soldering modules and features automatic nozzle activation, a process camera, and IR preheating. X-axis flexibility with a dual solder pot increases throughput and allows for the use of two different nozzles to accommodate varying soldering needs. Soldering trials at the Ersa Demo Center confirmed the system´s capabilities. “We brought actual assemblies to solder on the demo machine. The results were excellent – our very first run was virtually perfect, and the few remaining optimizations were straightforward,” MTL Managing Director Fabian Larem reports.

Transition from hand soldering to selective machine soldering

Today, MTL uses the VERSAFLOW ONE X to replace time-consuming, manual soldering processes for standard products, ensuring consistent, repeatable results, even for double-sided assemblies. This increases productivity and improves cost-effectiveness. The machine also provides redundancy for the existing wave soldering system, which has been in use for many years and is expected to be replaced in the medium term. “Thanks to our selective soldering system, we can now serve customers who were previously outside our focus,” states Fabian Larem. “And we can move jobs from wave soldering to selective soldering.”

MTL´s management also highlights the service-oriented sales process characterized by excellent responsiveness and flexibility. When the delivery of the new soldering system was delayed, MTL produced the first and second customer batches on an Ersa machine in Wertheim. “That went far beyond a feasibility study and was remarkable both professionally and personally. Many thanks to everyone involved,” says Larem. As the VERSAFLOW ONE X was an introductory unit, MTL also benefited from an especially attractive price. “Of course, it takes some time to get used to a new machine, but we´ve settled in by now – and we´re very pleased with the VERSAFLOW ONE X.”

The new selective soldering system is currently operating on a single-shift basis but can handle additional orders at any time. “We made this investment with a certain optimism, trusting that the economy would pick up again,” says Fabian Larem. With its expanded machine base, MTL can now offer power electronics in XXL sizes. “We are specifically targeting companies many times our size and with the most stringent audit requirements. To the best of our knowledge, there are only a few suppliers in Germany that combine comparable agility, flexibility, and technological depth within one organization,” Larem says.

Shaping the future with process expertise

The trend toward more demanding assemblies is increasing the need for comprehensive process expertise. MTL is well-prepared for the future, whether in selective soldering or related technologies, thanks to its partnership with Ersa. “Our partnership with Ersa is equal in every way. Despite the difference in company size, the technical exchange is always respectful and solution-oriented. Ersa doesn´t just supply machines. Rather, as a system supplier, they support us throughout the entire process with know-how, advice, and technologies that provide long-term added value,” concludes Fabian Larem. At Productronica 2025, MTL will keep an eye on the industry´s technological developments and evaluate further investment opportunities. With the VERSAFLOW ONE X, the company is well-positioned to meet its customers´ growing needs.