Aluminum components have been used in automotive engineering since the early 20th century. For almost as long, automotive experts have been comparing the various processes for manufacturing these parts in terms of cost-effectiveness and suitability - a comparison of low-pressure casting and die casting.

First things first: both low-pressure die casting and die casting have applications in which the respective process is best suited. This depends heavily on the complexity of the component, the quantity and the available manufacturing costs. So here's a comparison: How do the low-pressure die casting and die casting processes work?

Die casting

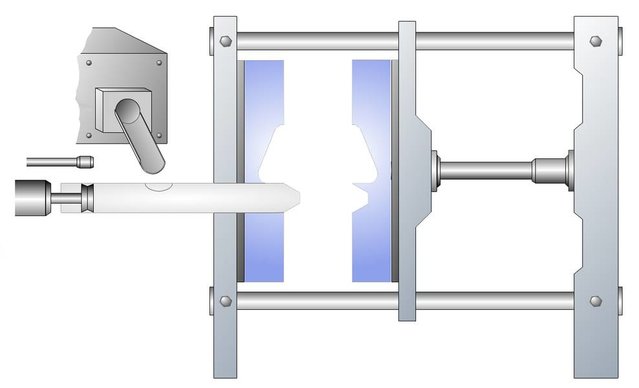

The halves of the die-casting mold are each mounted on a fixed and a movable machine plate of the horizontally aligned die-casting machine. Due to the high pressure of up to 1,200 bar during casting, locking devices with high locking forces are required to hold the die casting mold together. As these have a relatively high melting point, cold chamber die casting machines are mainly used for aluminum alloys. Here, the casting set is located outside the molten metal. The liquid metal is dosed into the filling chamber and the piston shoots the metal into the mold. When the metal has solidified, the two halves of the mold open and the casting is automatically pushed out of the mold with the help of ejector pins.

Low-pressure casting (LP casting)

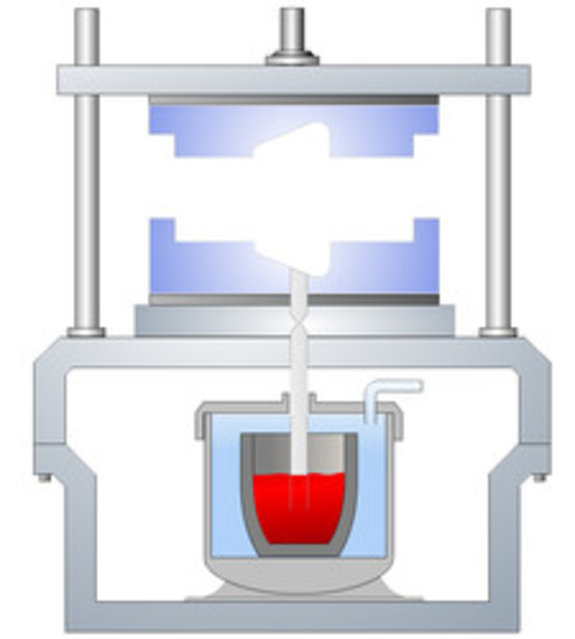

As with die casting, the halves of the mold (die) are mounted on a fixed and a movable machine plate, but the machine is arranged vertically. The holding furnace for the molten metal is located under the fixed clamping plate - by applying a pressure of up to max. 1 bar to the furnace, the molten metal (primarily aluminum, but also magnesium) rises from below into the mold cavity, usually a permanent mold, by means of riser(s). However, sand molds are also possible. This causes the liquid metal to move upwards against the force of gravity. After the mold has been filled, the pressure is maintained during solidification in order to enable replenishment to compensate for the volume deficit (shrinkage cavity) during the transition from the liquid to the solid state. This naturally requires solidification from top to bottom in the most directional way possible.

Demands on the automotive world

As is generally known, the industry is forced to increase efficiency and reduce CO2 emissions. For engine technology, ND-Guss uses the possibility of using sand cores to implement a closed-deck design of the engine block - this means that the openings previously required in die casting on the cylinder head surface in the engine block to demold the cooling jacket contour are no longer needed in the low-pressure process. This enables a more rigid engine block design, which, together with the improved material properties, saves weight and increases performance. A significant contribution to "downsizing". This technology is also used in structural and chassis components, where large frame parts are "hollow-cast" using sand cores and the component weight is significantly reduced.

From the luxury class to the mass segment

Due to the excellent material properties, the low-pressure process has been known in the automotive industry for decades, but until a few years ago it was only used in the luxury segment due to the relatively long casting cycles, where lower quantities and higher unit costs were expected. Despite the achievable qualities, die casting had to admit defeat in the mass segment due to the extremely fast cycle times. The background: although a die-casting machine costs around four times as much as a low-pressure casting machine, until a few years ago the latter was around 4 to 6 times faster in the casting cycle. The aim was therefore to make the low-pressure process more economical, i.e. faster. One big step was to increase the size of the entire machine. As low pressure casting does not require enormous clamping forces due to the high casting pressures, the machine size is not dictated by the weight of the casting - in the low pressure casting sector, for example, 110 kg are cast in a mold.

The Kurtz team was able to increase the plate dimensions required for the mold in such a way that molds with multiple cavities can be used. Today, for example, engine blocks are cast twice - this corresponds to a reduction of the casting cycle by a whopping 50%! By additionally optimizing the cooling circuits on the machine side to accelerate solidification, for example, a further 25% of cycle time could be saved. The low-pressure casting system scores further points in terms of the space required by the machines, as the vertical machine alignment means that two low-pressure casting machines can be set up where one die casting machine was previously located. Incidentally, the circulation material is also significantly reduced, saving money. These developments make the low-pressure process more than competitive in many areas. Contact us and let's work together to get your specifications into the right shape!

Die casting

| Advantages | Disadvantages | |||

|

| |||

|

| |||

|

| |||

|

| |||

|

Low pressure casting

| Advantages | Disadvantages | |||

|

| |||

|

| |||

| ||||

| ||||

| ||||

|