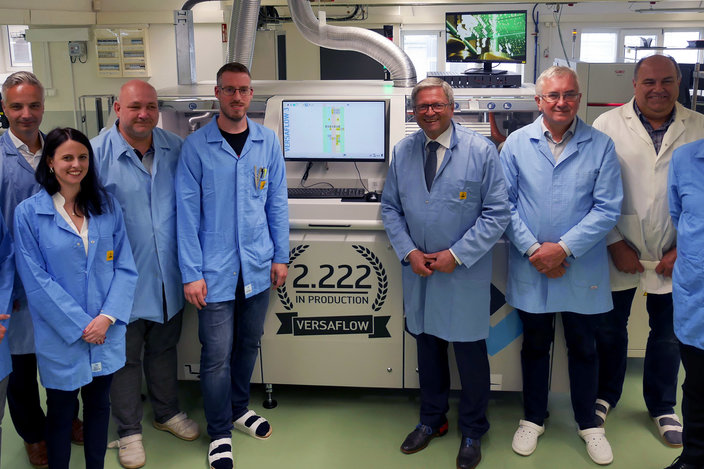

Top quality from the first circuit board! VERSAFLOW 3 No. 2,222 goes to INOTECH CZ User Report

No. 2,222 of the successful VERSAFLOW 3 model goes to INOTECH from the Czech Republic

INOTECH electronic s.r.o., based in Kaplice in the Czech Republic, specializes in the assembly of printed circuit boards for small and medium-sized series, but can also handle the construction of prototypes. With a modern machine park and an experienced team, INOTECH offers its customers services and products at the leading edge of electronics production. In mid-2024, the Czech EMS service provider added an Ersa VERSAFLOW 3/35 selective soldering system to its machine park, which already includes six Ersa systems. For system supplier Ersa, this is the 2,222nd machine installed in the successful third generation of machines.

The EMS service provider INOTECH electronic s.r.o. can already look back on 30 years of company history, even though the company initially operated under a different name. Shortly after the company was founded in 1994, a business partner from Germany enquired whether INOTECH would also manufacture electro-inductive components. They said yes and went into business. This was the basis for today´s medium-sized company with 100 employees, which produces a wide range of printed circuit boards for customers from various sectors, such as automotive, smart home and medical technology. Injection molding technology is also part of the production process at INOTECH, meaning that plastic products including packaging can be manufactured in addition to electronic assemblies. This is an invaluable advantage for customers, as INOTECH can become a general contractor for electronics production. For example, INOTECH produces remote controls on a large scale for the leading manufacturer of remote controls – here in Kaplice, 30 km south of Budweis, 20,000 units are produced every day. The company not only manufactures electronics and housings, they are also “married” here and packaged ready for shipment. That makes 20,000 PCBs a day and 11 million components to be assembled every month. “We can already make an adjustment to our processes during the initial assembly and then also offer the associated series production, so that the customer only needs one contact to realize their product,” says engineer Pavel Goldfinger, who has been Managing Director of INOTECH electronic since 2004.

Selective soldering – expanding flexibility

But there are also an increasing number of projects with significantly smaller batch sizes and special requirements for the soldering process – especially in the Czech Republic. “With the VERSAFLOW 3/35 selective soldering system, we have now found the perfect addition to our machine park to also realize prototypes and smaller batch sizes.

This has already enabled us to win several new projects with Czech customers for INOTECH. Another great example is an eight-layer curved circuit board for a German camper van manufacturer, which ensures the vehicle´s solar power supply – that works perfectly on the VERSAFLOW 3/35. And we´re talking about 1,500 assemblies here, so a relatively small number of units,” says INOTECH Production Manager Michal Mikeš. Ersa General Sales Director Rainer Krauss adds: “The advantage of selective soldering is the high flexibility and that you can simply stay longer in a place with more copper or where holes are difficult to reach and thus achieve first-class penetration without using a mask. The fact that this technology is a worldwide success model is proven by the serial number 2,222 that has now been reached – I am very pleased that this machine has been delivered here to INOTECH in the Czech Republic, where six other Ersa systems are already in active use!”

Highest throughput with the smallest footprint

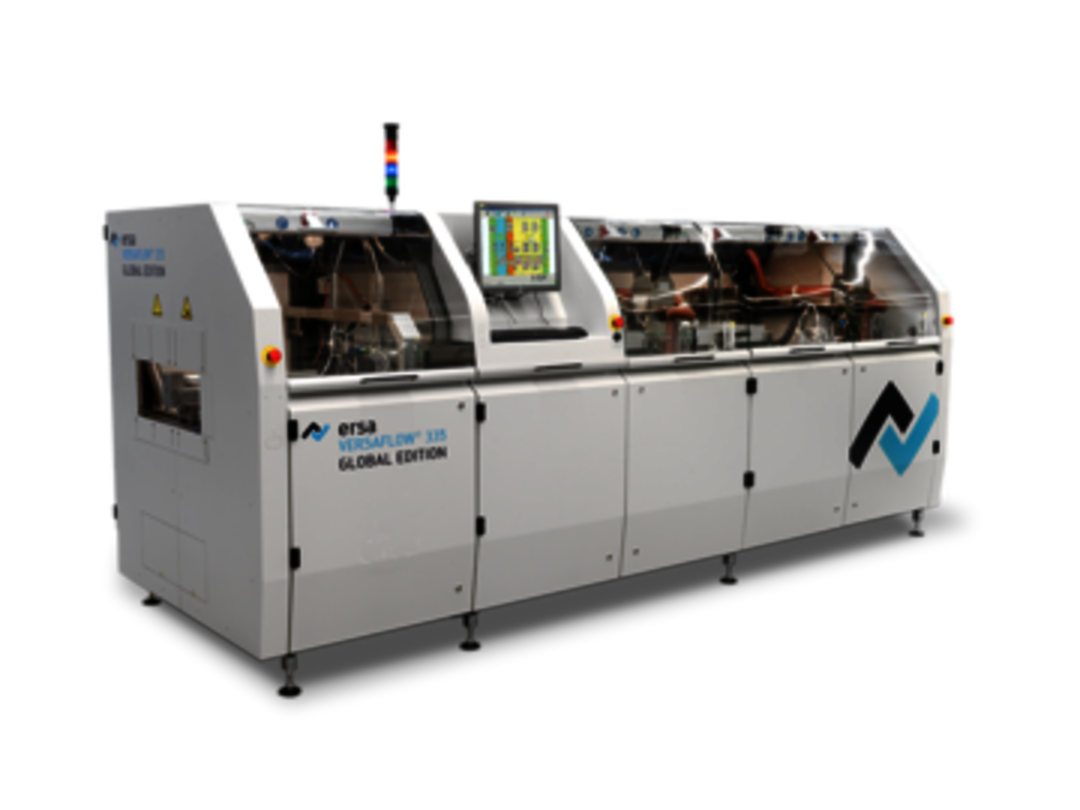

The topic of selective soldering and VERSAFLOW 3/35 was carefully tested using benchmarks – because the INOTECH team wants to ensure that the products ordered from the Czech EMS service provider can be produced safely and to the required quality. This involved extensive tests at the Ersa Demo Center in Wertheim – the Czech engineers´ eyes lit up right from the first runs. Test PCB 01: successful, zero rejects! INOTECH was particularly impressed by the modular design of the VERSAFLOW systems, which includes an option for an additional solder pot – allowing cycle times to be shortened and productivity to be significantly increased if required. The VERSAFLOW 3/35 inline selective system offers maximum flexibility and maximum throughput with minimum space requirements (L x W x H: 2,450/1,750/1,650 mm) at an attractive price.

For INOTECH and Ersa, this is another milestone in the successful cooperation that began with numerous Ersa soldering stations and Ersa soldering tools and entered the Ersa machine world in 2006 – with an N-WAVE 330 wave soldering system which is still in operation. This was followed by two VERSAPRINT 2 stencil printers, three HOTFLOW 4/14 reflow soldering systems and now, as the seventh system, the VERSAFLOW 3/35 selective soldering system. “Allow me to make a comment: Of course, Ersa builds excellent machines, but that would be nothing without the right service. We get this service – either directly from Ersa in Germany or from the Czech distributor PBT Rožnov. I would like to thank everyone involved for the excellent cooperation in the past and look forward to upcoming common projects,” said engineer Karel Mach, owner of INOTECH electronic s.r.o., who showed the plans for the expansion of INOTECH production at the farewell.

VERSAFLOW 3/35 GLOBAL EDITION

Pre-configured soldering machines with leading selective soldering technology