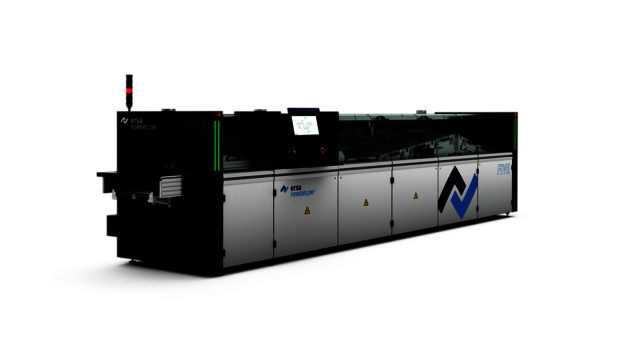

VERSAFLOW FIVE + POWERFLOW FIVE score points for flexibility and efficiency New standards in Soldering Technology

Electronics Production faces increasingly complex challenges: growing product diversity, higher quality requirements, and at the same time pressure to reduce production costs and produce more sustainably. In this challenging environment, Ersa offers two innovative soldering systems, VERSAFLOW FIVE and POWERFLOW FIVE, which set new standards in terms of flexibility, energy efficiency, and total cost of ownership (TCO) thanks to intelligent technologies.

Both systems follow a common philosophy: maximum adaptability to different production requirements to ensure the highest soldering quality while minimizing resource consumption. While the VERSAFLOW FIVE selective soldering system handles complex mixed assemblies and variable production volumes, the POWERFLOW FIVE wave soldering system complements the portfolio for high-throughput continuous processes.

VERSAFLOW FIVE: SELECTIVE SOLDERING TECHNOLOGY REDEFINED

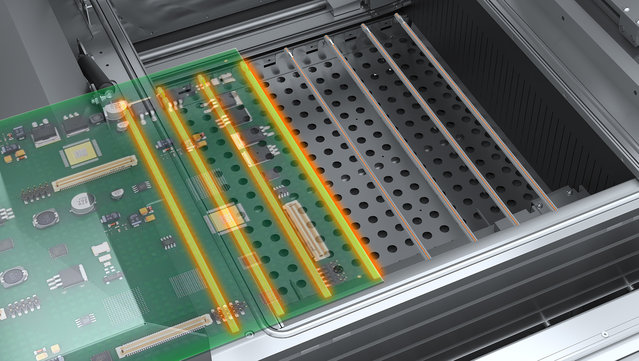

The VERSAFLOW FIVE revolutionizes selective soldering with several key technologies that complement each other:

- VERSAFLEX 2.0 – autonomous parallel processing: The advanced VERSAFLEX module enables completely independent processing of printed circuit boards by two separate solder pots in the same soldering module. Each axis portal executes its program completely autonomously without the need for synchronization. For the first time, both solder pots cover the entire soldering area of 685 x 508 mm. Collision monitoring ensures safe travel paths for both solder pots. This decoupling of the systems not only creates higher throughput rates, but also enables different soldering tasks to be processed simultaneously in one workspace.

- Extended PCB format flexibility: With a maximum PCB length of 685 mm (+30% compared to other selective soldering systems) and optimized processing of two flat assemblies up to 320 mm in length, the VERSAFLOW FIVE offers ideal production conditions for an exceptionally wide range of assemblies. The new, more robust z-axis with a stroke of 110 mm significantly expands the range of possible applications for complex applications with tall components.

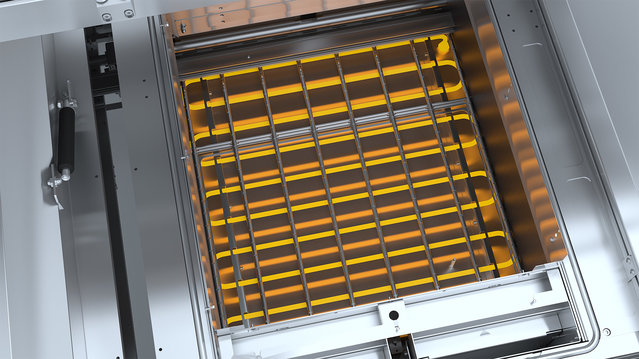

- Matrix heating system: The preheating system of the VERSAFLOW FIVE is designed as a matrix. With this innovative heating system, the infrared emitters of the heating surface can be divided into six separate segments that can be controlled individually.

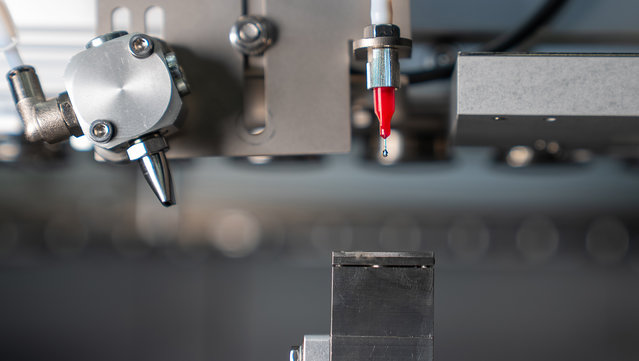

- Automated system components: Automatic flux nozzle cleaning significantly reduces the need for manual intervention, as it automatically removes contamination from dropjet spray heads, thus maintaining consistent spray quality. Especially in phases with low staff availability – such as night shifts or line start-ups – it ensures high process reliability and minimizes downtime.

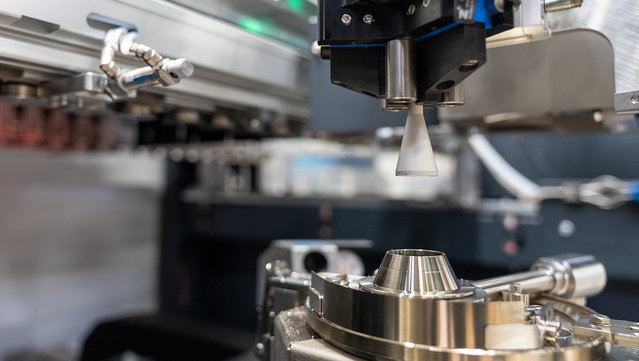

- Automatic nozzle changer: enables solder nozzles to be changed without manual intervention. The machine automatically converts to the nozzle geometry required by the soldering program – both during operation and when setting up for new orders – thereby increasing availability and process reliability.

Module-related LED strips directly on the respective machine modules serve as visual status indicators. They enable operating personnel to see the current operating status at a glance. This allows manual interventions to be carried out in a targeted and faster manner without the operator first having to check the HMI. This increases efficiency during setup and maintenance processes and reduces downtime.

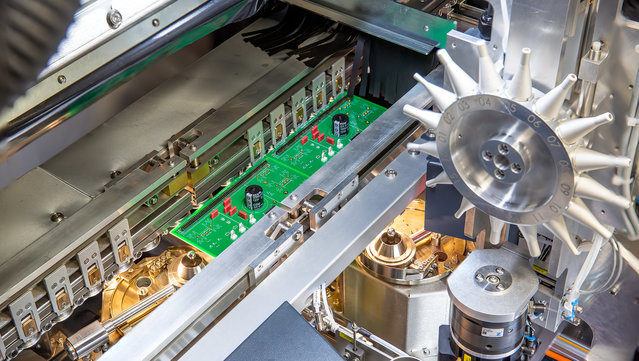

POWERFLOW FIVE: NEXT-GENERATION WAVE SOLDERING

The POWERFLOW FIVE combines proven technology with innovative features:

- Dynamic Z-axis control and sequential soldering via nozzle height adjustment: The POWERFLOW FIVE comes with a new dynamic Z-axis control for sequential soldering. The new Z-axis allows distances between the wave former and flat assembly of 5 to 18 mm. The second wave former is also independently adjustable in height. The whole process is program-controlled and addresses the increasing challenge of mixed assemblies, where power electronics and digital components have different thermal requirements. The dynamic Z-axis also offers more options when using solder masks. In addition, the travel speed of the axis has been significantly increased, making sequential soldering even more flexible. Thanks to a new type of control compensation, the wave height is kept stable even when the pot and wave former are moving in all possible combinations.

- Automatic wave height control and adjustment: A constant overflow at the wave formers ensures reproducible soldering results regardless of disturbance variables. For this reason, the POWERFLOW FIVE has integrated measurement technology at the solder wave that checks the solder wave height at regular intervals and automatically adjusts the solder overflow as needed. This ensures uniform wetting and constant pressure at the nozzle outlet.

- Hybrid heating technology: The combination of medium-wave radiation and convection increases the heat transfer efficiency of the heating cassettes by up to 30% with the same energy consumption.

- SMART IR Radiation: Eight pairs of controllable infrared emitters automatically switch to standby mode as soon as the flat assembly reaches the next pair of infrared emitters. This intelligent control reduces the energy consumption of the heating system by up to 10%.

- SMART ELEMENTS® Process Gas Cleaning: This POWERFLOW FIVE technology extends operating times by up to 30% through reduced contamination, minimizing both energy costs for frequent cleaning cycles and production downtime. Granulated absorption technology reduces residues by up to 60% while improving soldering quality.

The two new FIVE models from Ersa impress with measurable improvements

Flexibility as a competitive advantage

VERSAFLOW FIVE enables different soldering tasks to be processed simultaneously in one module thanks to VERSAFLEX 2.0. In concrete terms, this means that while one pot is processing a complex automotive control board, for example, the second pot can solder a medical technology application in parallel – without waiting times or setup processes. In trials, efficiency gains of up to 40% were achieved with mixed production batches. The expanded range of PCB formats that can be soldered with the VERSAFLOW FIVE significantly reduces the need for different machine types. A single system can process both small sensor boards and large power assemblies such as inverters or on-board chargers, reducing investment costs and simplifying production planning.

The extended z-axis now offers a maximum stroke of 110 mm, allowing for tall components on the solder side. In combination with long solder nozzles and optimized program control, even greater clearance can be achieved, enabling soldering in deep housings and similar applications. Another part of the new flexibility is the optimized sequence control of PCB handling, which enables very high throughput rates for smaller PCBs up to 320 mm. Flexibility and maximum productivity are therefore not a contradiction in the VERSAFLOW FIVE.

In the POWERFLOW FIVE, dynamic nozzle height adjustment enables new flexibility for the optimal processing of mixed assemblies. By changing the nozzle distance to the underside of the PCB, combined with wave speed adjustment, both the heat transfer and the solder contact time can be changed. A wider range of assemblies also requires adjustments to the transport system. The POWERFLOW FIVE implements new heavy-duty transport systems for PCBs weighing up to 25 kg, which further extend maintenance intervals and allow wear parts to be replaced quickly and easily.

Energy efficiency through adaptive systems

The new matrix heating system of the VERSAFLOW FIVE enables adaptive heat input during preheating. Only the heating zones that are actually needed are activated, which reduces energy consumption in proportion to the heated area. The savings therefore depend on the product, but in an average production mix, an average of 20% energy savings are possible with infrared heaters. Since infrared heaters are usually the largest energy consumers in a selective soldering system, the savings potential is considerable.

The POWERFLOW FIVE also achieves an enormous increase in efficiency in heat transfer thanks to its hybrid heating technology. Combined with the individual control of the infrared heaters, this results in an average energy saving of 10% in preheating compared to conventional systems. Measures to reduce maintenance and downtime on both systems also improve uptime and energy efficiency. After all, unproductive times are one of the key factors in optimizing a product´s carbon footprint.

TCO optimization through automation

The VERSAFLOW FIVE´s automatic nozzle changer significantly reduces downtime for manual setup processes. In a high-mix/low-volume production environment, an average of three shifts were possible without manual intervention, with two to three product changes per shift. The investment pays for itself in a typical production environment after just a few months through savings in personnel costs and increased machine availability. In addition, process reliability is increased by eliminating manual intervention. The nozzles are always set up in the same, optimal manner.

Automatic flux nozzle cleaning ensures consistent spray quality without manual intervention. This not only reduces personnel costs, but also minimizes rejects due to uneven flux distribution. Human influence is reduced, improving process stability and reliability. With the new status display concept, which shows the status of the individual modules using LED strips, maintenance work can be started more quickly and, above all, in a more targeted manner. Production personnel can see at a glance the current status of each module. With the POWERFLOW FIVE, wave height control enables a permanently stable overflow height of the solder at the wave former, which leads to better reproducible soldering results and thus reduces scrap costs. The extended maintenance intervals resulting from the low-wear heavy-duty transport system further reduce ongoing operating costs. SMART ELEMENTS® process gas cleaning extends operating times by filtering out contaminants that would otherwise settle in the machine. Tests have shown that residues can be reduced by up to 60%.

Sustainable success through intelligent technology

Flexibility as a guarantee for the future

Both systems address the dramatic shift in electronics production towards greater product variety and shorter product life cycles. The VERSAFLOW FIVE, with its ability to process different products in parallel, and the POWERFLOW FIVE, with its adaptability to different component types, offer manufacturing companies the flexibility they need to respond quickly to market changes.

Energy efficiency as a sustainability factor and competitive advantage

The energy-saving technologies implemented go beyond mere cost savings. They make a measurable contribution to reducing the carbon footprint in electronics manufacturing. For the POWERFLOW FIVE, a combination of all measures resulted in an energy saving of 10% for typical production. Based on typical annual production, this corresponds to a CO₂ reduction of several tons! In times of rising energy costs, energy efficiency is becoming a decisive competitive factor. Companies that invest in energy-efficient soldering technology today secure long-term cost advantages while meeting the increasing sustainability requirements of their customers.

Equipped for the future

Both VERSAFLOW FIVE and POWERFLOW FIVE feature the latest software features from Ersa. Both use the award-winning ERSASOFT 5 user interface. HERMES and IPC-CFX interfaces are available, as are other MES connections and the connection to Kurtz Ersa CONNECT. In addition to the smart features in the digital world, the VERSAFLOW FIVE also supports the shop floor with its intelligent status display at the module level.

CONCLUSION: The VERSAFLOW FIVE and POWERFLOW FIVE mark the next big step in soldering technology. They prove that maximum technical performance, economic efficiency, and ecological responsibility are not contradictions, but can reinforce each other. For electronics manufacturers, this means that investments in these technologies are not only investments in today´s productivity, but also in tomorrow´s competitiveness.

The consistent focus on flexibility, energy efficiency, and TCO optimization makes both systems future-proof solutions that are able to meet the increasing demands of electronics manufacturing while also making an important contribution to sustainable production. Combined with the numerous added values offered by Kurtz Ersa, this results in an unbeatable overall package.

Categories

Your Contact

Rainer Krauss

Overall Sales Manager