Wertheim/München

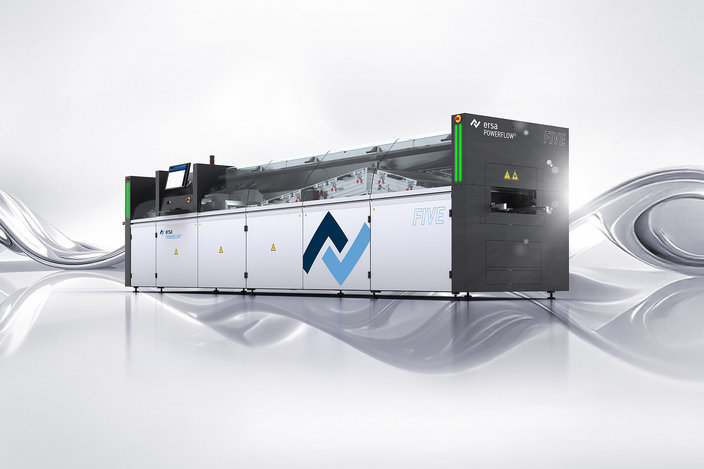

With the new POWERFLOW FIVE, Ersa is presenting an innovative wave soldering system at Productronica 2025 which sets new standards in terms of performance, flexibility, energy efficiency, and total cost of ownership (TCO) due to advanced technologies. This system is targeted at electronics manufacturers with high production volumes and demanding applications, as in power electronics, for example. The design of Ersa´s new flagship is focused on adaptive production processes. POWERFLOW FIVE adjusts flexibly to different requirements while ensuring maximum efficiency and economic viability.

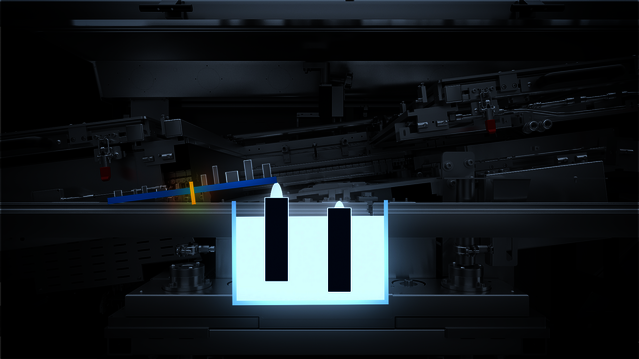

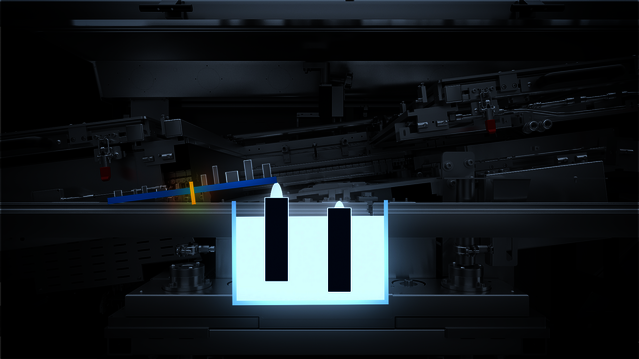

With its dynamic Z-axis and sequential soldering through nozzle height adjustment, the POWERFLOW FIVE optimally meets the dynamic demands of modern applications, particularly in the areas of e-mobility, 5G, smart living, and smart grid. Products in these areas increasingly feature mixed assemblies consisting of traditional and high-performance components. Individually adjustable distances between solder nozzle and printed circuit board (PCB), as well as automatic wave height control and adjustment, ensure consistent soldering quality and minimal scrap rates. The wave former distances can be set between 5 and 18 mm and can be moved both in parallel and independently of each other. This programmable flexibility allows for optimal adaptation to mixed assemblies where power electronics and digital components have different thermal requirements. Due to an additional stroke of 20 mm, it is possible to use longer nozzles to reliably solder components with larger heights.

To guarantee consistent, reproducible soldering results, the POWERFLOW FIVE is equipped with integrated measuring technology that regularly monitors the solder wave height and automatically adjusts the solder overflow as needed. This always maintains consistent wetting and stable pressure at the nozzle outlet. Productivity is enhanced by smart, maintenance-friendly features such as SMART ELEMENTS® for process gas cleaning. The hybrid heating system combines medium-wave infrared emitters and convection heating to achieve up to 50% more efficient heat transfer with the same energy consumption. Additionally, the modules can be easily removed for maintenance in just 15 minutes.

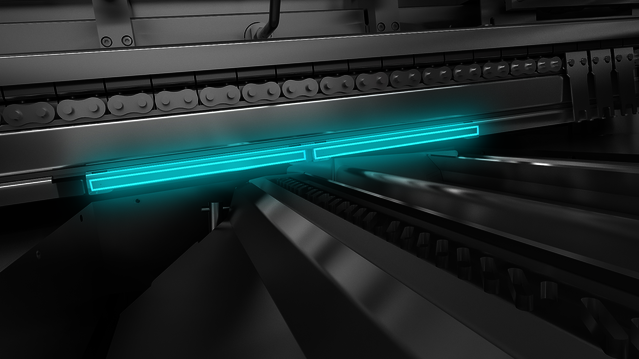

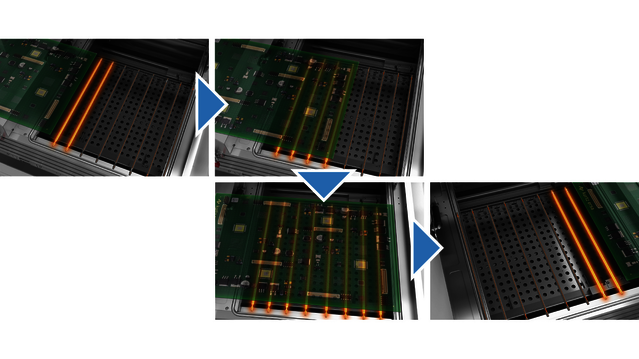

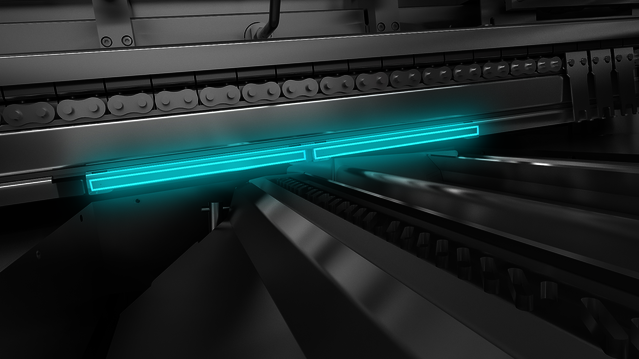

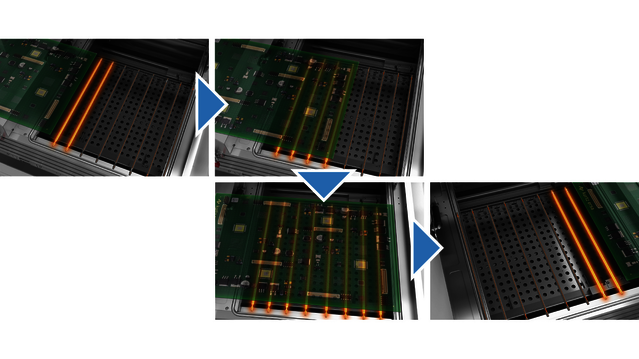

SMART IR RADIATION features eight infrared emitters that can be controlled in pairs. This reduces energy consumption by up to 10%. Only the emitters beneath the PCB are activated; the rest automatically go into standby mode. To cover the expanded range of applications, the POWERFLOW FIVE is equipped with a new heavy-duty conveyor that safely handles PCBs weighing up to 25 kg. It is designed for long maintenance intervals, and wear parts can be replaced quickly and easily. The POWERFLOW FIVE is ideally positioned for todays and future generations of electronics by combining top technical performance with economic efficiency and ecological responsibility.

Categories

Wertheim/München

With the new POWERFLOW FIVE, Ersa is presenting an innovative wave soldering system at Productronica 2025 which sets new standards in terms of performance, flexibility, energy efficiency, and total cost of ownership (TCO) due to advanced technologies. This system is targeted at electronics manufacturers with high production volumes and demanding applications, as in power electronics, for example. The design of Ersa´s new flagship is focused on adaptive production processes. POWERFLOW FIVE adjusts flexibly to different requirements while ensuring maximum efficiency and economic viability.

With its dynamic Z-axis and sequential soldering through nozzle height adjustment, the POWERFLOW FIVE optimally meets the dynamic demands of modern applications, particularly in the areas of e-mobility, 5G, smart living, and smart grid. Products in these areas increasingly feature mixed assemblies consisting of traditional and high-performance components. Individually adjustable distances between solder nozzle and printed circuit board (PCB), as well as automatic wave height control and adjustment, ensure consistent soldering quality and minimal scrap rates. The wave former distances can be set between 5 and 18 mm and can be moved both in parallel and independently of each other. This programmable flexibility allows for optimal adaptation to mixed assemblies where power electronics and digital components have different thermal requirements. Due to an additional stroke of 20 mm, it is possible to use longer nozzles to reliably solder components with larger heights.

To guarantee consistent, reproducible soldering results, the POWERFLOW FIVE is equipped with integrated measuring technology that regularly monitors the solder wave height and automatically adjusts the solder overflow as needed. This always maintains consistent wetting and stable pressure at the nozzle outlet. Productivity is enhanced by smart, maintenance-friendly features such as SMART ELEMENTS® for process gas cleaning. The hybrid heating system combines medium-wave infrared emitters and convection heating to achieve up to 50% more efficient heat transfer with the same energy consumption. Additionally, the modules can be easily removed for maintenance in just 15 minutes.

SMART IR RADIATION features eight infrared emitters that can be controlled in pairs. This reduces energy consumption by up to 10%. Only the emitters beneath the PCB are activated; the rest automatically go into standby mode. To cover the expanded range of applications, the POWERFLOW FIVE is equipped with a new heavy-duty conveyor that safely handles PCBs weighing up to 25 kg. It is designed for long maintenance intervals, and wear parts can be replaced quickly and easily. The POWERFLOW FIVE is ideally positioned for todays and future generations of electronics by combining top technical performance with economic efficiency and ecological responsibility.