POWERFLOW FIVE Ersa Wave Soldering

The new flagship for ultimate wave soldering

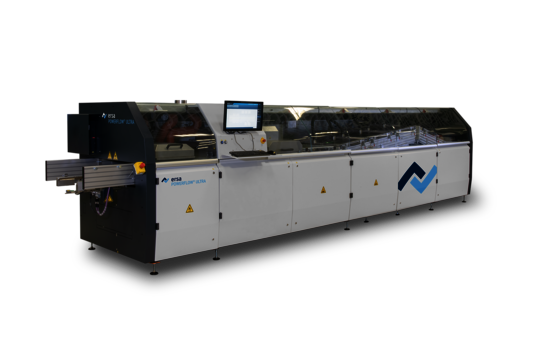

The Ersa POWERFLOW FIVE is the latest generation of Ersa wave soldering systems and sets the benchmark in the ultra-high segment. It is specifically designed to meet the dynamic requirements of today´s and tomorrow´s markets - for example, in the areas of e-mobility, 5G, and smart grids. The POWERFLOW FIVE is aimed at electronics manufacturers with a particular focus on demanding applications in power electronics.

1/6

Ersa Wave Soldering

POWERFLOW FIVE

The POWERFLOW FIVE is the latest generation of Ersa wave soldering systems and sets the benchmark in the ultra-high segment - perfect for e-mobility, 5G, and smart grids.

2/6

Ersa Wave Soldering

POWERFLOW FIVE

The POWERFLOW FIVE is aimed at electronics manufacturers with a particular focus on demanding applications in power electronics.

3/6

Ersa Wave Soldering

POWERFLOW FIVE

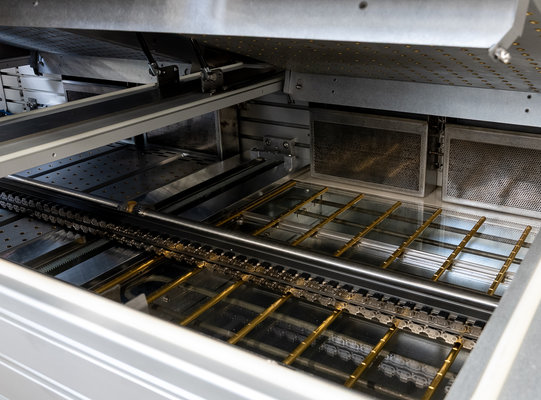

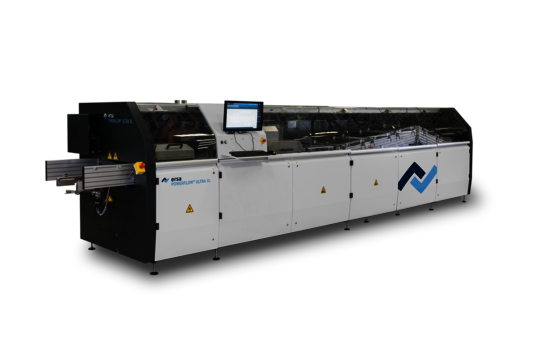

To cover the expanded range of applications, the POWERFLOW FIVE features a new heavy-duty transport system that safely transports circuit boards weighing up to 25 kg.

4/6

Ersa Wave Soldering

POWERFLOW FIVE

The granulate-based SMART ELEMENTS® system absorbs contaminants highly efficiently, extends operating times by minimizing maintenance times, and thus achieves maximum productivity.

5/6

Ersa Wave Soldering

POWERFLOW FIVE

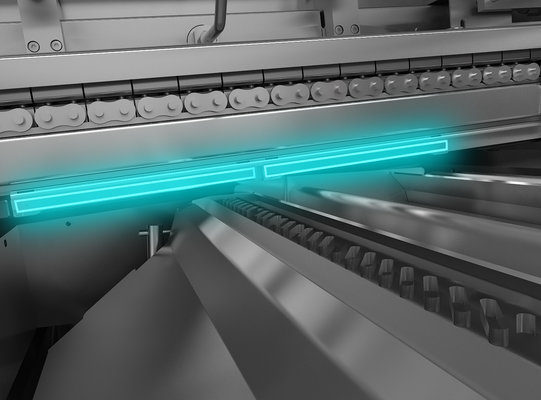

The new preheater uses SMART IR RADIATION with eight pairs of controllable infrared emitters that automatically switch to standby mode as soon as the flat assembly reaches the next pair of infrared emitters.

6/6

Ersa Wave Soldering

POWERFLOW FIVE

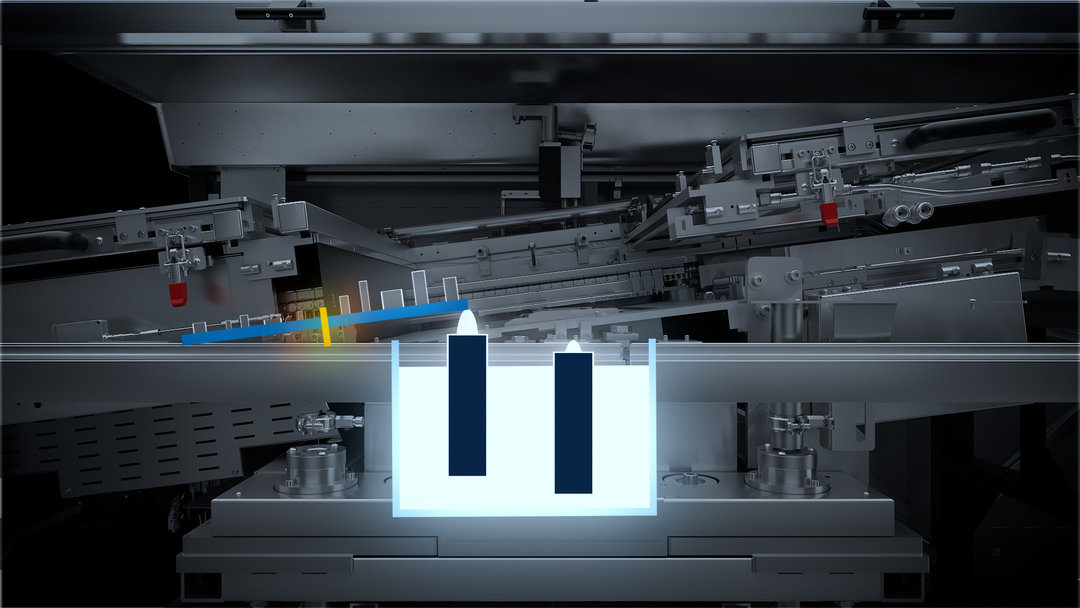

The soldering module enables 1.5 mio. maintenance-free strokes and ensures maximum availability - consistent wave height at all times thanks to new measurement technology that checks the soldering wave height at regular intervals and automatically adjusts the solder overflow as needed.

Technology Highlights POWERFLOW FIVEErsa Wave Soldering

- Soldering module with new dynamic z-axis and sequential soldering

- SMART WAVE GUARD for precise monitoring of wave height

- Heavy-duty transport up to 25 kg

- Highly efficient SMART ELEMENTS® process gas purification

- Energy savings through hybrid heating and SMART IR RADIATION

POWERFLOW FIVEErsa Wave Soldering

POWERFLOW FIVE

POWERFLOW FIVEErsa Wave Soldering

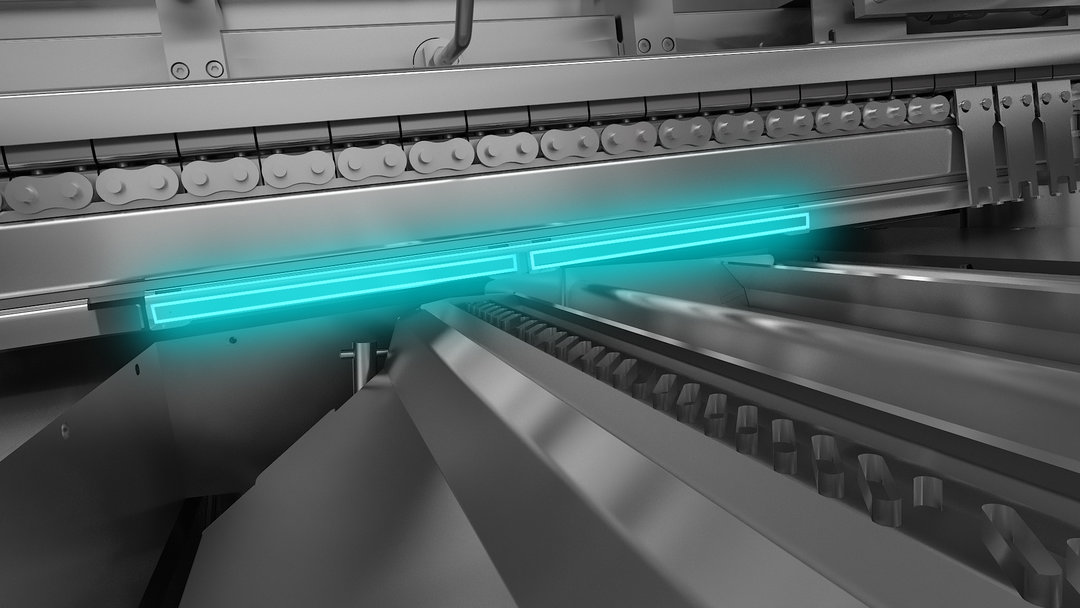

Dynamic z-axis and sequential soldering 2.0

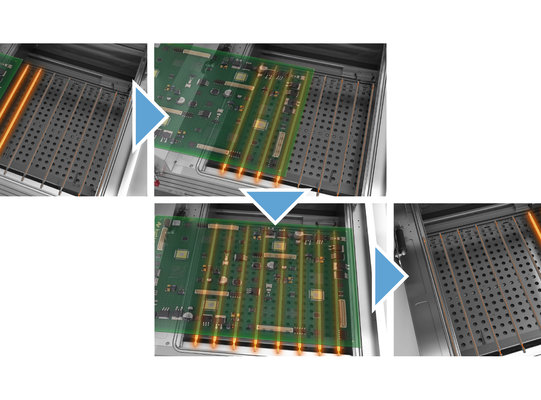

In the electronics production of the future, more and more power electronic and digital components will be combined on the same product. It is therefore necessary to be able to adjust the distance between nozzles and circuit boards individually for each product and to specify different distances within a product. The POWERFLOW FIVE features a new dynamic z-axis control for sequential soldering 2.0 - this new z-axis allows distances between the waveform generator and flat assembly of 5 to 18 mm. The second waveform generator is also independently adjustable in height. All settings can be conveniently adjusted via the operating software. The independent nozzle adjustment dynamically adapts to different requirements. With an accuracy of 0.1 mm and 10 individually controllable sections, sequential soldering 2.0 guarantees perfect solder joints for even the most complex mixed-technology assemblies.

SMART WAVE GUARD wave height control and adjustment

The soldering module enables 1.5 mio. maintenance-free strokes, guaranteeing maximum availability. To keep the wave height constant, the POWERFLOW FIVE features new measurement technology that checks the solder wave height at regular intervals and automatically adjusts the solder overflow if necessary. This ensures uniform wetting and constant pressure at the nozzle outlet.