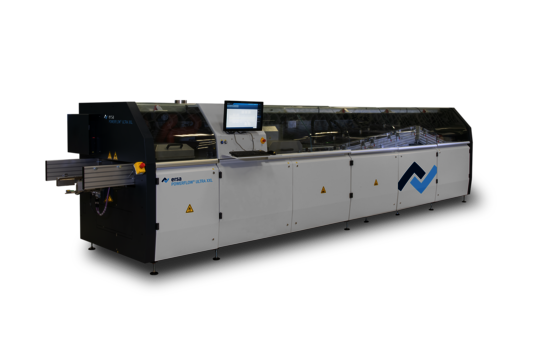

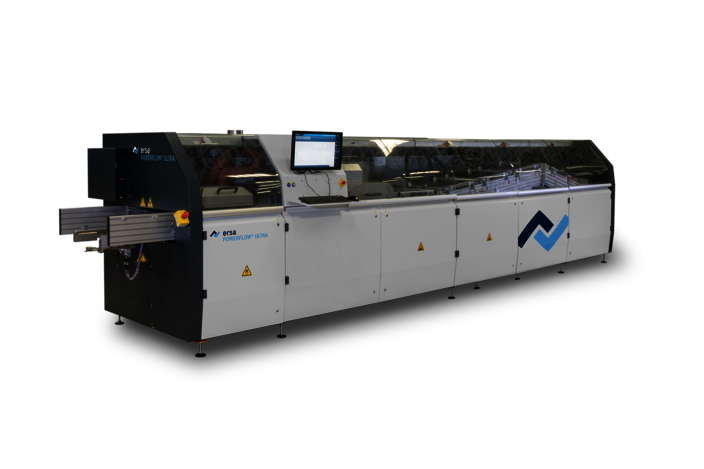

POWERFLOW ULTRA full-tunnel nitrogen wave soldering system Ersa Wave Soldering

The POWERFLOW ULTRA is the innovation in the wave soldering product portfolio of Ersa GmbH. This full-tunnel wave soldering machine meets current and future flexibility and throughput requirements. The machine is available with both frame and finger transport. Working widths from 330 to 610 mm (XXL version) are possible. It can also be used to solder server boards for 5G communication.

Technology Highlights POWERFLOW ULTRAErsa Wave Soldering

High-end full-tunnel nitrogen wave soldering system

- Maximum flexibility, maximum throughput and maximum availability

- Modular, flexible and individually expandable preheating concept, variably configurable in length and output (can also be retrofitted)

- Award-winning ERSASOFT 5 operating software based on a database > Ready for Industry 4.0

- Finger and frame transport with different working widths

Applications POWERFLOW Wave Soldering MachineErsa Wave Soldering

POWERFLOW ULTRAErsa Videos

POWERFLOW ULTRAErsa Wave Soldering

New soldering module for the POWERFLOW ULTRA

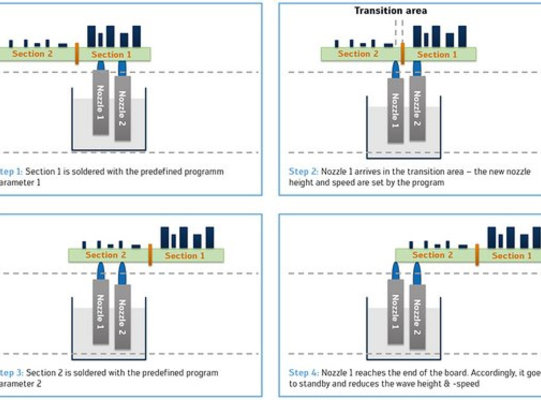

At the heart of the POWERFLOW ULTRA is the new soldering module with unique process control and flexibility. Its innovative drive achieves travel speeds of up to 5 mm/s. The distance between the soldering nozzle and the PCB is defined via the ERSASOFT 5 operating software. This allows assemblies to be soldered at a precise distance. The nozzle distance and solder wave height can also be adjusted as required within an assembly.

For this purpose, the PCB is divided into sectors under program control, which are stored with parameters. This means that each sector can be soldered with individual configurations, ensuring highly flexible processes. In addition, the contact time of the solder wave with the assembly can be stored in the soldering program. This offers maximum process control when moving the assembly into and out of the solder wave. In combination with the nozzle spacing, an optimum solder flow is achieved, resulting in perfect solder joints - especially for assemblies that are equipped with a high proportion of digital components in addition to power electronics.

Ersa Success StoriesPOWERFLOW ULTRA

POWERFLOW ULTRAErsa Wave Soldering

Technical data

Transport Systems

- Finger transport, frame transport

- Max. Transport speed 2.5 m/min

- Max. Working width 406 mm

- Max. PCB structures up to 150 mm

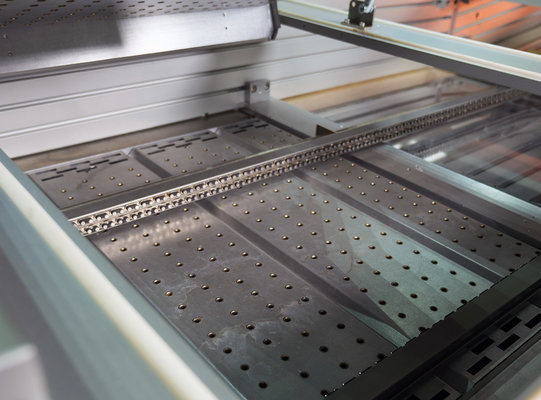

Preheating/Soldering Module

- Preheating: heat transfer by means of convection, medium-wave radiation and short-wave radiation

- Individually configurable up to a preheating length of 3,000 mm

- Soldering module: 525 to 725 kg solder content depending on configuration