POWERFLOW ONE Ersa Wave Soldering

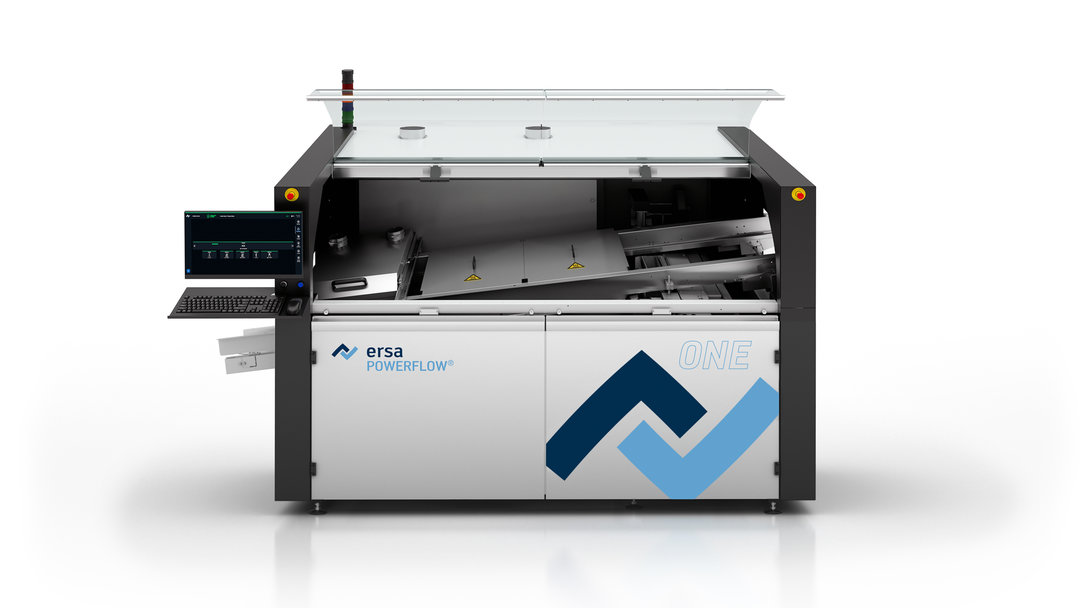

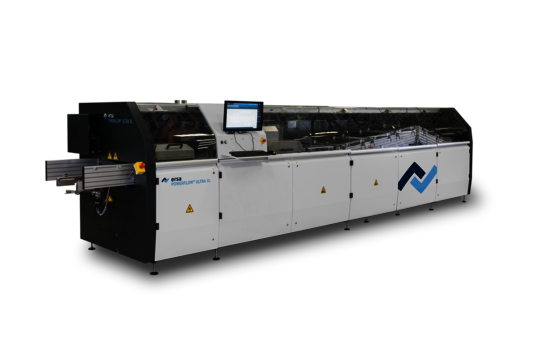

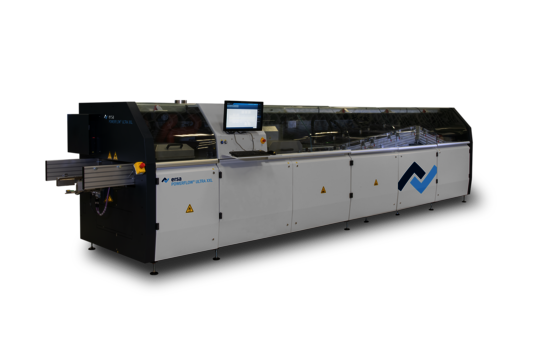

The POWERFLOW ONE is the ideal entry-level machine for small electronics manufacturers who rely on proven Ersa quality and reliability. The machine has a small footprint and reduces downtime to an absolute minimum. This is made possible by the use of established components such as solder pots and heaters, which have proven themselves over many years in the POWERFLOW line of systems.

1/5

Ersa Wave Soldering

POWERFLOW ONE

The POWERFLOW ONE offers the ideal introduction to wave soldering with proven Ersa quality and reliability.

2/5

Ersa Wave Soldering

POWERFLOW ONE

The compact POWERFLOW ONE, measuring just 2.90 m in length, enables cost-effective entry into the Ersa wave soldering portfolio through the use of established components such as solder pots and heaters.

3/5

Ersa Wave Soldering

POWERFLOW ONE

The POWERFLOW ONE is the first Ersa machine with the new KE.ON software platform - state-of-the-art, future-proof, modular, and expandable at any time.

4/5

Ersa Wave Soldering

POWERFLOW ONE

Cost-effective entry-level solution with a small footprint - yet offering 100% proven Ersa quality and reliability!

5/5

Ersa Wave Soldering

POWERFLOW ONE

Added values - as an Ersa customer, you get access to process support, a global service network, spare parts, training courses, events, and e-learning.

Technology Highlights POWERFLOW ONEErsa Wave Soldering

- Enter the world of POWERFLOW with a length of only 2.90 m

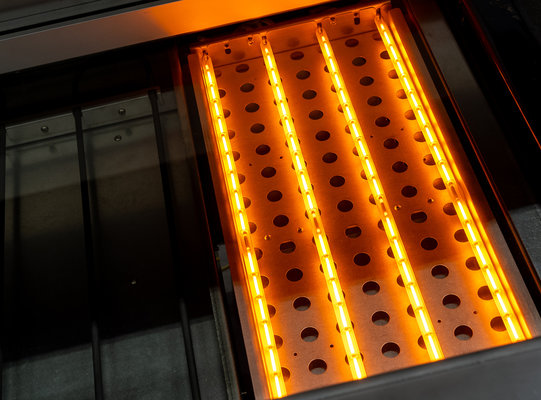

- Powerful preheating with 3 cassettes (2x medium wave, 1x bright radiator)

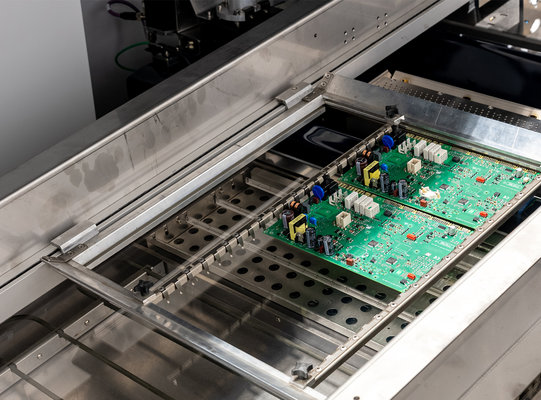

- Proven crucible technology with a filling volume of only 345 kg

- Nitrogen option

- Optional finger transport

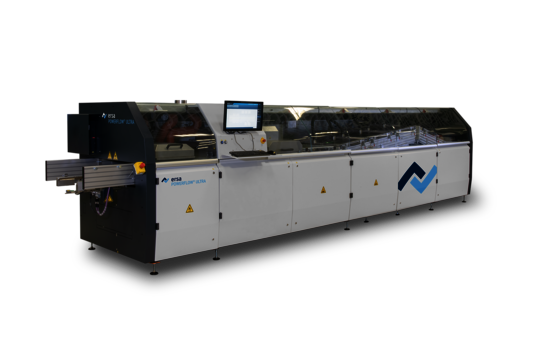

- Optional inline capability

Your advantagesPOWERFLOW ONE

- Modular state-of-the-art software architecture

Equipped for future requirements in terms of security, stability, and flexibility - Optimized machine data acquisition

Efficient process design and smart features - Modern, intuitive user interface

Comprehensive user management and easy operation

POWERFLOW ONEErsa Wave Soldering

POWERFLOW ONE

Compact design and cost efficiencyPOWERFLOW ONE

The POWERFLOW ONE is a compact machine with a length of 2.90 m, which provides a cost-effective entry point into the Ersa wave soldering portfolio. It focuses on the essentials of wave soldering and combines excellent value for money with proven Ersa quality. The basic version has a wave former and is designed for stand-alone operation with a soldering frame. The reduced pot volume supports cost-efficient operation. Optional extensions allow upgrades and adaptations up to high-performance inline operation.