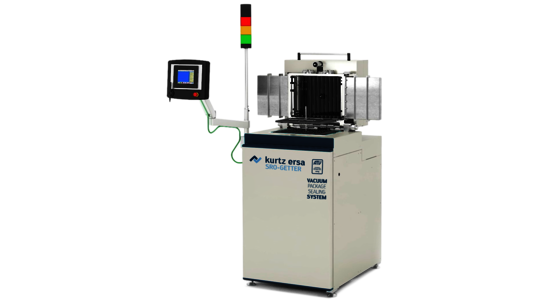

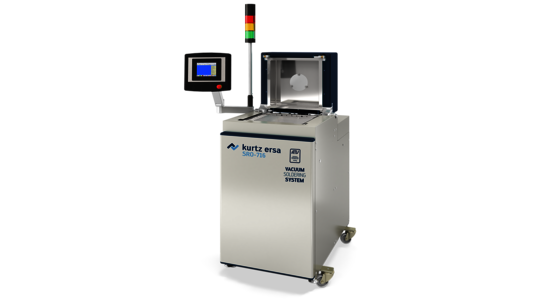

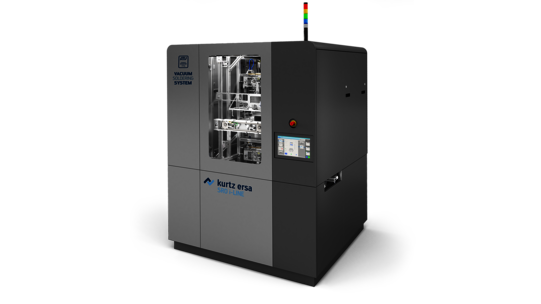

Kurtz Ersa Semicon GmbH is specialized in the development and distribution of high quality vacuum soldering systems that stand out with their precise temperature control and excellent homogeneity, which is essential for the requirements of semiconductor and microelectronics manufacturing. The portfolio includes customized solutions for universities, research institutes, laboratories and manufacturing companies. The SRO-i-Line is a massproduction system that offers significant advantages for applications in electromobility, renewable energies and defense due to its innovative infrared heating technology.

Vacuum soldering: precision and reliability in one chamber

Soldering technology in power electronics - essential for quality and reliability

Soldering technology in power electronics - essential for quality and reliability

In power electronics, solder joints play a key role in ensuring both reliable electrical connections and efficient heat dissipation. Their quality and reliability directly influence the overall performance, safety and lifetime of electronic systems. Modern applications in power modules, power semiconductors and MEMS/sensor packages place very high demands on solder materials and processes. Uniform wetting and a low void rate across large solder areas are essential to achieve stable, longlasting joints with excellent electrical and thermal properties.

Controlled soldering process in a closed chamber

Controlled soldering process in a closed chamber

In SRO systems the soldering process takes place in a closed process chamber. This allows the process atmosphere to be precisely defined and controlled. By repeatedly evacuating and refilling the chamber with high purity nitrogen, the oxygen level is reduced to below 3 ppm, which reliably prevents oxidation. The result: a reproducible process with consistent soldering quality, regardless of component size, material combination or assembly complexity. Users benefit from precise control, maximum process stability and optimal connection technology for power modules, MEMS packages and power electronics.

Oxide removal with formic acid

Oxide removal with formic acid

At temperatures above approximately 180 °C, formic acid reliably removes oxide layers from metals, enabling optimal wetting. The refillable system has no moving parts, which minimizes maintenance and increases operational reliability. This ensures process stability, which is essential for consistent quality and highest reproducibility in serial production.

Flexible application for complex and large-scale components

Flexible application for complex and large-scale components

Our soldering systems are designed for maximum flexibility. The components can be heated up directly via infrared or indirectly via heating plate, enabling the soldering of a wide range of products, including large and complex components such as heat exchangers or power modules. Due to customized heating plates and individually adjustable soldering recipes within the proprietary control software, the soldering profile can be precisely adapted to the thermal requirements of each component and solder. This ensures a homogeneous temperature distribution and uniform solder joints, even with challenging geometries.

Minimization of voids through vacuum technology

Minimization of voids through vacuum technology

Voids in solder joints can affect electrical and thermal conductivity, potentially leading to overheating, corrosion or early component failure. The use of vacuum during the peak zone of the soldering process reliably removes entrapped gas and minimizes void formation. This results in homogeneous solder joints with optimized heat transfer, which leads to significantly increased reliability and service life of power electronics.

Precise process control and flexible recipe adjustment

Precise process control and flexible recipe adjustment

The user friendly process software enables the operator to define, save and adjust all parameters individually, from evacuating the process chamber and controlling the process gases, to the temperature profile and controlled cooling in a nitrogen atmosphere. Each process step is fully documented and can be accessed at any time for quality assurance or process optimization. This ensures that the entire soldering process remains transparent, reproducible and traceable. This offers a significant advantage for applications with highest quality requirements.