January 13-15, 2026, Nuremberg

In mid-January, it will once again be time to say: Welcome to the Nuremberg Trade Fair, welcome to Kurtz Casting Solutions! At EUROGUSS 2026, we will be presenting the advantages of Kurtz Low Pressure Casting Technology, a highly efficient casting process that saves resources and money! We will also introduce you to our new Process Analysis Tool from Kurtz Service, which uses facts to show you the optimization potential of your production. In addition, we will be presenting our comprehensive range of services for the project planning of complete turnkey solutions.

Find out more about the Kurtz highlights you can expect at our booth in Hall 4A-329.

We look forward to seeing you in Nuremberg from 13 to 15 January!

You still need a ticket so we can meet:

Get your ticket for your visit to Kurtz.

Please send requests for individual appointments during EUROGUSS to:

Lena.Seifert@kurtzersa.de

Kurtz Highlights at EUROGUSS 2026

Low Pressure Technology

Low Pressure Technology

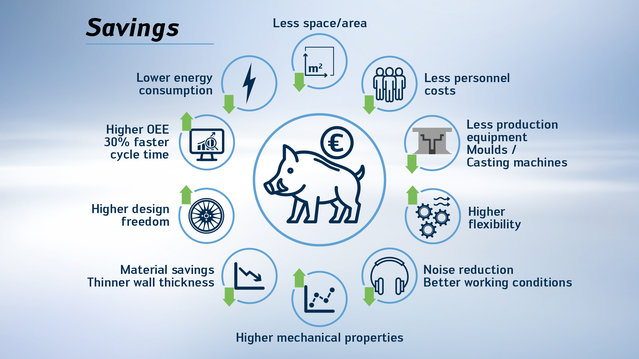

The optimal choice for forward-thinking companies. The Low Pressure Casting Technology offers a variety of cost-saving measures that make it a superior manufacturing process. Examples of the advantages that Low Pressure Casting can offer your company:

Energy efficiency: Thanks to lower pressures and temperatures, energy consumption is significantly reduced compared to traditional casting processes. This not only translates into lower energy costs, but also supports your company's sustainability goals.

Improved product quality: Low Pressure Casting enables continuous filling of the mould and improved solidification, which means that the parts produced have higher dimensional accuracy and less scrap is produced.

Reduction of scrap and rework: Higher precision and optimised process control can significantly minimise scrap. This leads to less material waste and less rework, which reduces production costs and increases profitability.

Ideal for companies that...

- want to increase the efficiency of their production

- want to become both cost-effective and environmentally friendly

- are looking for greater flexibility and design freedom

What are the benefits of LP technology? Visit us at our booth and we will discover the potential that Low Pressure Casting offers for your casting production!

Process Analysis with a new Tool

Process Analysis with a new Tool

The key to more efficiency lies in the process. Complex processes in the manufacture of aluminium castings require in-depth expertise. Thanks to our experience and numerous customer projects since 1983, we know how to analyze and further develop processes to achieve the highest quality and efficiency. Our service experts are now assisted by the new Process Analysis Tool. It enables the professional recording and visualization of process and machine data directly on site – even independently of the control system.

Ideal for ...

- processors with a focus on process optimization

- avoiding machine downtime

- visualization of the condition of assets

- potential analyses that sometimes even open up new production possibilities

Our colleagues in Nuremberg will be happy to explain how the Process Analysis Tool works!

Engineering Solutions for Greenfield & Brownfield Sites

Engineering Solutions for Greenfield & Brownfield Sites

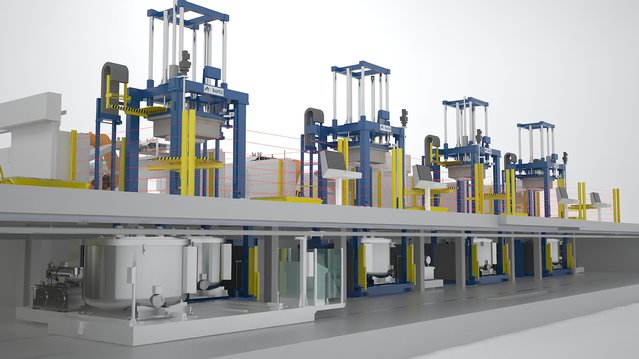

Analysis or redesign? Challenge us! Our engineering team implements complete manufacturing solutions with maximum productivity, flexibility, and cost-effectiveness at any desired location worldwide. Goals for redesigning your production: Reduce waste, eliminate bottlenecks, and find additional potential for improvement. Our engineering experts will ensure quality, productivity, and cost reduction for your cast part production.

Ideal for …

- consulting on the most suitable casting process

- demonstrating wasted potential

- overall view of the current casting process

- design of the entire production process, including melt processing, material transport, work concepts, and downstream processes

Are you interested in before-and-after examples? Come and visit us at our booth. We will be happy to give you an insight into implemented projects!

Does that sound exciting? We think so too! We are delighted to present our highlights to you. Our trade fair team is ready and looking forward to spending plenty of time with you in Nuremberg to discuss your application, your project, and your production.

See you in Nuremberg from January 13 to 15, 2026, in Hall 4A-329!