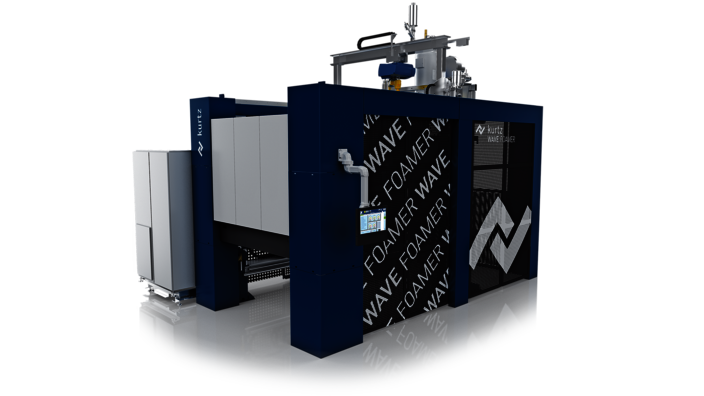

Kurtz WAVE FOAMER Shape Moulding Machines

Steamless Foaming - Smart Fusion

With the revolutionary RF technology, welding particle foams without steam becomes a reality! A complex media installation - in the form of a steam generation system or cooling tower installation with water basin - is no longer required. With the WAVE FOAMER, high-temperature resistant particle foams with welding temperatures up to 250 °C can be processed. In addition, a recycling rate of up to 100% is already achievable with EPS. Now achieve perfect core welding with the revolutionary Kurtz RF technology using electromagnetic waves - and save up to 90% energy costs (for EPS)!

Highlights Kurtz WAVE FOAMERShape Moulding Machines

Very high energy saving

Perfect core welding

For new particle foams with high temperature resistance

Ideal for high densities, e.g. EPS with over 200 g/l

No complex media installation

Production of moulded parts with high recycled content

Kurtz WAVE FOAMERShape Moulding Machines

Optiones

Robot systems for the insertion and removal of moulded parts

Quality inspection station e.g. weight determination or optical measurement

Barcode allocation

Conveyor systems for connection to packaging lines

Kurtz 4.0

Central Management System 4.0 - mobile control station, worldwide access

Insert/Eject Control 4.0 - optical forming/demolding control

Remote Service 4.0 - real-time troubleshooting