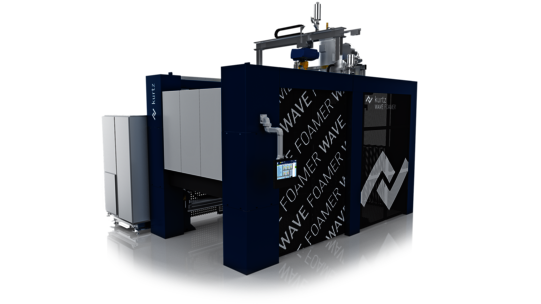

Kurtz POLY FOAMER Shape Moulding Machines

The benchmark in EPS

POLY FOAMER moulding machines are designed for EPS processing up to a maximum processing pressure of 1.5 bar and can be equipped with electric or hydraulic drives. The Kurtz machines can be optimized with all common handling options. You will be immediately impressed by the advantages of the POLY FOAMER series. Benefit from freedoms you have always wanted from an automatic molding machine!

Advantages Kurtz POLY FOAMERShape Moulding Machines

- Freedom in the choice of mould size

- Freedom in the choice of process technology

- Freedom in changing the mould

- Freedom in the choice of process

- Generous opening stroke

- Freedom in drive technology - electric or hydraulic

- POLY FOAMER sizes M and L are also available with fully electric drive as an alternative

- Quality

Kurtz POLY FOAMER

Kurtz POLY FOAMERShape Moulding Machines

Options

Tool change with guide rollers

Folding ejector plate

Oil cooler

Dual density function

Core pullers

Mould change crane manual/electric

Regrind mixing station

Air connection for high and low pressure

Central vacuum system

Working platform for mould change

Volumetric water dosing with pressure increase

Mould temperature and foam pressure measurement

Remote start function

Data memory

Material conveying

Interval cooling

Filling injectors with i-CAP

Kurtz 4.0

- Central Management 4.0 - mobile control station, worldwide access

- Filler injector with i-CAP - intelligent filler maintenance

- Remote Service 4.0 - problem solving in real time