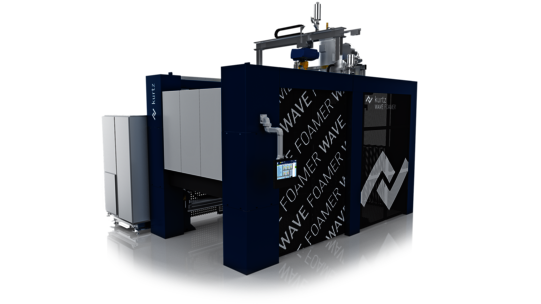

Kurtz ROTO FOAMER Shape Moulding Machines

Foaming - It´s so easy!

The Kurtz ROTO FOAMER is a specialist for moulded part production with inserts, such as those needed in the automotive industry. Its areas of application are in high-end EPP/EPS processing (insert moulding). The rotating steam chamber allows the mould to be loaded with inserts during moulded part production. The Kurtz ROTO FOAMER offers maximum productivity with low manpower requirements. The production area can be optimally utilized due to the compact design.

Highlights Kurtz ROTO FOAMERShape Moulding Machines

Mould sizes - 2 models up to 2.5 m2 foaming area

Simultaneous foaming and inserting

Shortest cycle times, high availability

Manual or automatic insertion

Lowest energy consumption

Longer maintenance intervals, best accessibility

Proven energy efficiency

Space-saving design

1,500 mm stroke

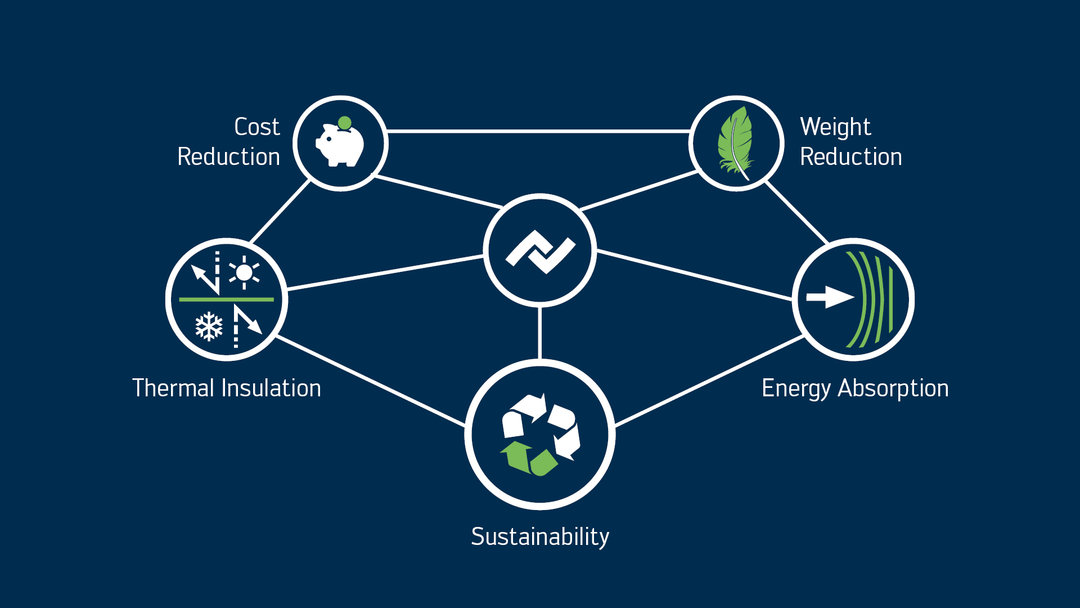

Areas of Application Kurtz ROTO FOAMERShape Moulding Machines

Kurtz ROTO FOAMERShape Moulding Machines

Options

Roboter systems for insert and removal of mouldings

Quality test station, e.g. weight or optical measurement

Conveying systems connecting to packaging line

Printing systems

Kurtz 4.0

Central Management 4.0 - mobile control station, worldwide access

Filler injector with i-CAP - intelligent filler maintenance

Remote Service 4.0 - problem solving in real time