Wertheim/Munich

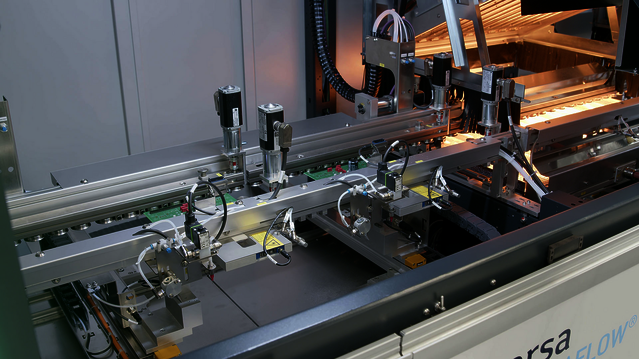

With the new VERSAFLOW FIVE, Ersa is presenting the new benchmark in high-end selective soldering at Productronica 2025. Having been developed for the most demanding industries - from automotive and aerospace to industrial electronics - it offers an unprecedented combination of throughput, process reliability, ease of use, and energy efficiency. Optimized for a wide range of different PCB formats (up to 685 mm in length), the machine also features a new, modern design.

In high-end electronics manufacturing, manual setup and maintenance tasks cost valuable production hours every day, tie up expensive specialist personnel, and increase the risk of process deviations. The Ersa VERSAFLOW FIVE meets this challenge with innovative features such as VERSAFLEX 2.0, automatic flux nozzle cleaning, automatic solder nozzle changer, matrix bottom heating, and CAD expert mode. These features optimize production processes, increase efficiency and enable electronics manufacturers targeting high volumes with varying requirements to achieve maximum productivity and uncompromising quality while minimizing the consumption of resources.

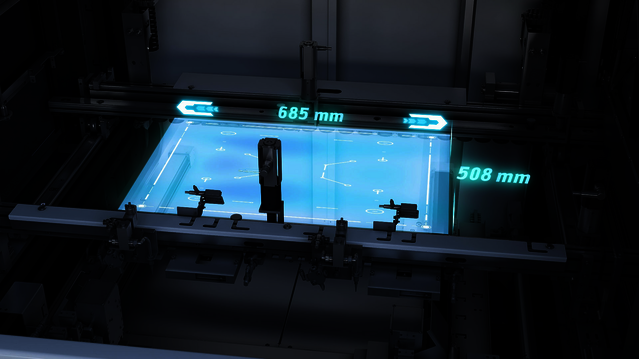

VERSAFLOW FIVE is the first generation of machines to incorporate the newly developed VERSAFLEX 2.0 solder module, which enables exceptional format flexibility. In addition to standard sizes, XL boards up to 685 mm in length can be processed. A second stopper allows two PCBs, each 320 mm in length, to be soldered simultaneously without prior synchronization, enabling output increases in the double-digit percentage range. In synchronous mode, both axes move parallel at a fixed distance, resulting in consistent soldering quality and significantly reduced cycle times when processing panels. In asynchronous mode, on the other hand, the axis systems operate independently, each with its own soldering program. This allows two circuit boards with different nozzle geometries or solder alloys to be processed simultaneously. The integrated collision monitoring ensures safe operation at any time. The maximum PCB width is 508 mm, the maximum PCB weight is 12 kg.

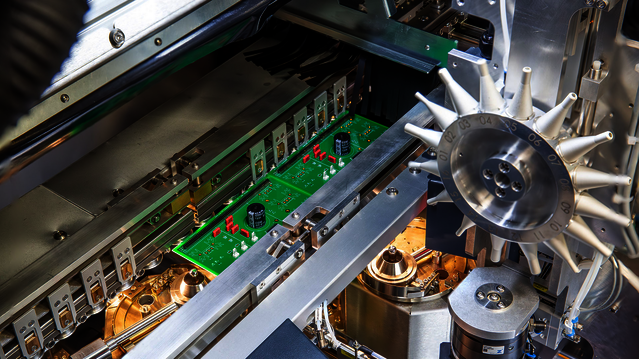

Another highlight of VERSAFLOW FIVE is the automatic nozzle changer, which allows solder nozzles to be changed without manual intervention. The machine automatically adjusts to the nozzle geometry required by the soldering program - both during operation and when setting up for new jobs - thereby increasing availability and process reliability. This is especially valuable in manufacturing environments with frequent program changes and limited operator presence and represents another step toward autonomous production. The preheater of the VERSAFLOW FIVE has been designed as a matrix. With this innovative heating system, the infrared emitters of the heating zone can be divided into six separate segments that can be controlled individually. Consequently, each assembly can be heated precisely according to specific requirements. This reduces thermal stress, ensures more consistent temperatures, and increases energy efficiency - a decisive advantage, especially for complex assemblies.

The VERSAFLOW FIVE embodies a new era in high-end selective soldering - offering maximum format flexibility and energy efficiency, shorter setup times, higher productivity - all with maximum quality, process stability, and ease of use. It covers an extremely wide range of assembly sizes and opens completely new product and order options for electronics manufacturers without the need for machine changes. Thus, VERSAFLOW FIVE is the ideal solution for companies seeking peak performance today while remaining competitive in the future.

Categories

Wertheim/Munich

With the new VERSAFLOW FIVE, Ersa is presenting the new benchmark in high-end selective soldering at Productronica 2025. Having been developed for the most demanding industries - from automotive and aerospace to industrial electronics - it offers an unprecedented combination of throughput, process reliability, ease of use, and energy efficiency. Optimized for a wide range of different PCB formats (up to 685 mm in length), the machine also features a new, modern design.

In high-end electronics manufacturing, manual setup and maintenance tasks cost valuable production hours every day, tie up expensive specialist personnel, and increase the risk of process deviations. The Ersa VERSAFLOW FIVE meets this challenge with innovative features such as VERSAFLEX 2.0, automatic flux nozzle cleaning, automatic solder nozzle changer, matrix bottom heating, and CAD expert mode. These features optimize production processes, increase efficiency and enable electronics manufacturers targeting high volumes with varying requirements to achieve maximum productivity and uncompromising quality while minimizing the consumption of resources.

VERSAFLOW FIVE is the first generation of machines to incorporate the newly developed VERSAFLEX 2.0 solder module, which enables exceptional format flexibility. In addition to standard sizes, XL boards up to 685 mm in length can be processed. A second stopper allows two PCBs, each 320 mm in length, to be soldered simultaneously without prior synchronization, enabling output increases in the double-digit percentage range. In synchronous mode, both axes move parallel at a fixed distance, resulting in consistent soldering quality and significantly reduced cycle times when processing panels. In asynchronous mode, on the other hand, the axis systems operate independently, each with its own soldering program. This allows two circuit boards with different nozzle geometries or solder alloys to be processed simultaneously. The integrated collision monitoring ensures safe operation at any time. The maximum PCB width is 508 mm, the maximum PCB weight is 12 kg.

Another highlight of VERSAFLOW FIVE is the automatic nozzle changer, which allows solder nozzles to be changed without manual intervention. The machine automatically adjusts to the nozzle geometry required by the soldering program - both during operation and when setting up for new jobs - thereby increasing availability and process reliability. This is especially valuable in manufacturing environments with frequent program changes and limited operator presence and represents another step toward autonomous production. The preheater of the VERSAFLOW FIVE has been designed as a matrix. With this innovative heating system, the infrared emitters of the heating zone can be divided into six separate segments that can be controlled individually. Consequently, each assembly can be heated precisely according to specific requirements. This reduces thermal stress, ensures more consistent temperatures, and increases energy efficiency - a decisive advantage, especially for complex assemblies.

The VERSAFLOW FIVE embodies a new era in high-end selective soldering - offering maximum format flexibility and energy efficiency, shorter setup times, higher productivity - all with maximum quality, process stability, and ease of use. It covers an extremely wide range of assembly sizes and opens completely new product and order options for electronics manufacturers without the need for machine changes. Thus, VERSAFLOW FIVE is the ideal solution for companies seeking peak performance today while remaining competitive in the future.