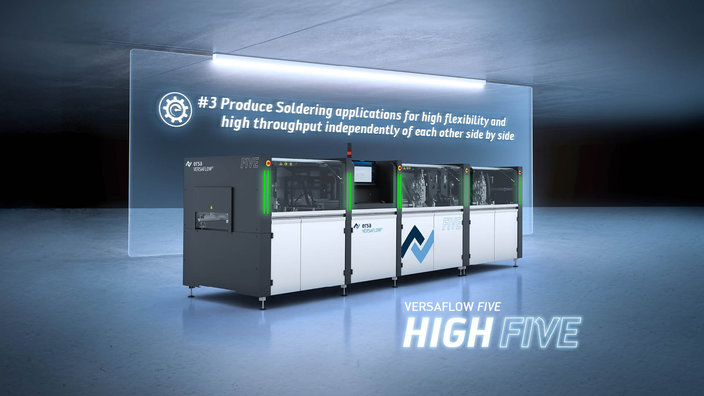

VERSAFLOW FIVE - HIGH FIVE for ultimate selective soldering Ersa Selective Soldering

Flexibility and throughput without compromise.

1/6

Ersa Selective Soldering

VERSAFLOW FIVE

HIGH FIVE for ultimate selective soldering. Flexibility and throughput without compromise!

2/6

Ersa Selective Soldering

VERSAFLOW FIVE

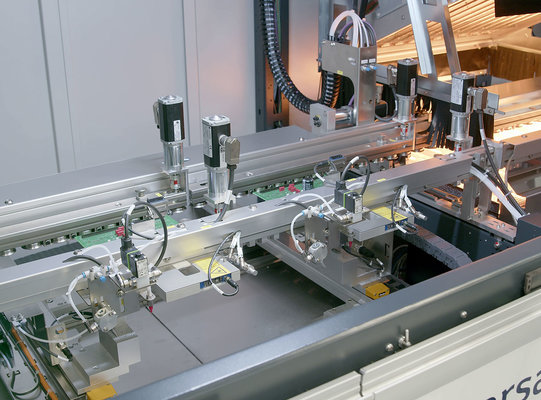

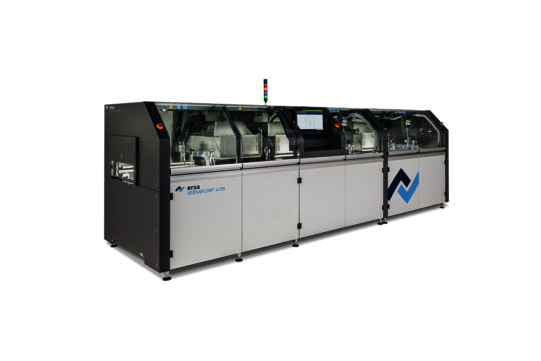

With a high degree of automation, the VERSAFLOW FIVE enables autonomous production and significant productivity gains. Ideal for electronics manufacturers with high production volumes and frequently changing requirements.

3/6

Ersa Selective Soldering

VERSAFLOW FIVE

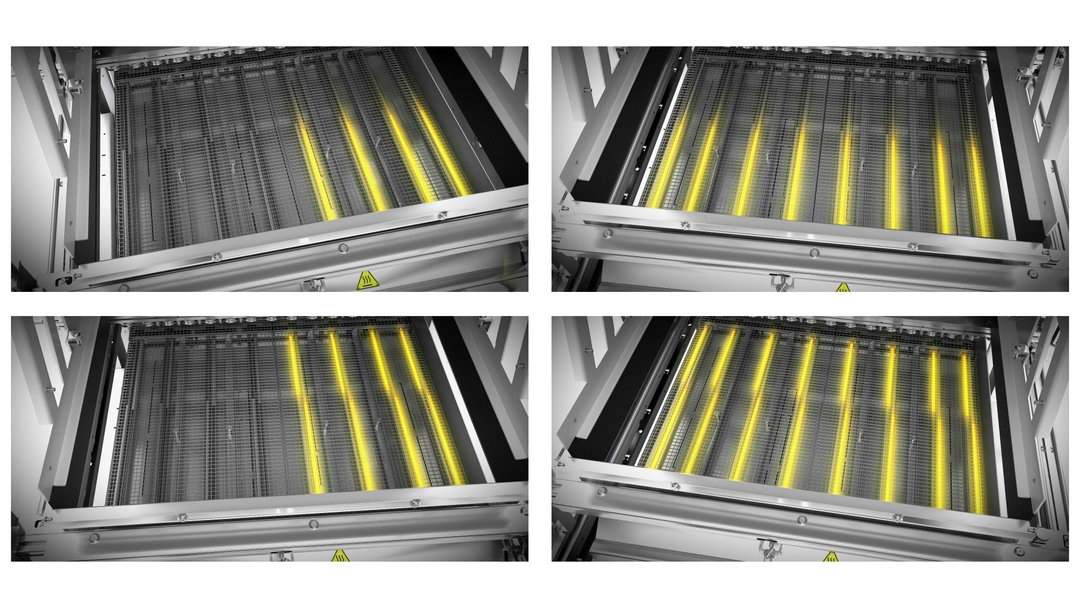

The multi-segment, individually controllable matrix heating system of the VERSAFLOW FIVE is an innovative heating system that allows the heating area to be adapted to the PCB format in order to increase energy efficiency.

4/6

Ersa Selective Soldering

VERSAFLOW FIVE

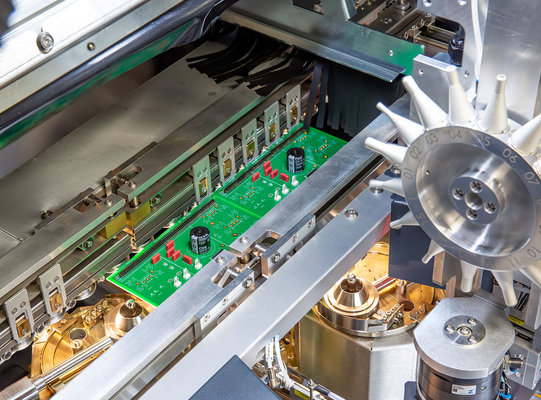

The VERSAFLOW FIVE is the first generation of machines to feature the new VERSAFLEX 2.0 module, which enables two circuit boards to be processed completely in parallel and independently of each other within a single module without any mutual waiting times, thereby maximizing throughput and batch sizes.

5/6

Ersa Selective Soldering

VERSAFLOW FIVE

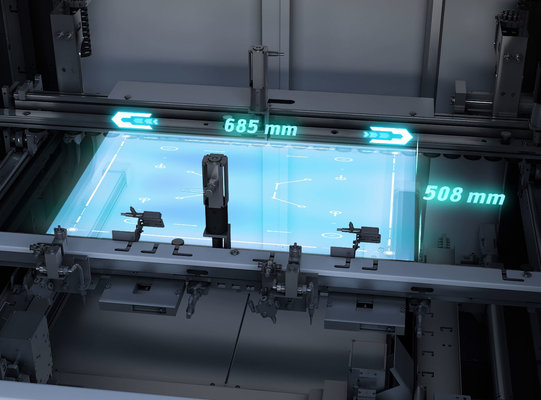

When XL assemblies in PCB format measuring up to 685 x 508 mm need to be processed reliably – VERSAFLOW FIVE!

6/6

Ersa Selective Soldering

VERSAFLOW FIVE

The expert mode in CAD Assistant 4 enables manual routing of flux and solder modules to further optimize throughput and cycle time. This allows you to specify the order in which the flux modules or solder modules process a circuit board.

Technology Highlights VERSAFLOW FIVEErsa Selective Soldering

- Automatic nozzle changer and automatic flux nozzle cleaning

- Matrix heating with segmented heating surfaces for flexible heating

- VERSAFLOW 2.0 with synchronous and asynchronous mode

- For assembly formats up to 685 x 508 mm or 2 PCBs up to 350 x 508 mm

- CAD expert mode

Your advantagesSelective soldering with the VERSAFLOW FIVE

- The next step toward autonomous production

- Component-friendly and energy-saving solution saves costs and resources

- Produce different soldering tasks independently side by side for high flexibility and high throughput

- Enables processing of one XL board or 2x standard formats

- Enables manual routing to optimize throughput and cycle time

VERSAFLOW FIVEErsa Selective Soldering

VERSAFLOW FIVEErsa Videos

VERSAFLOW FIVEErsa Selective Soldering

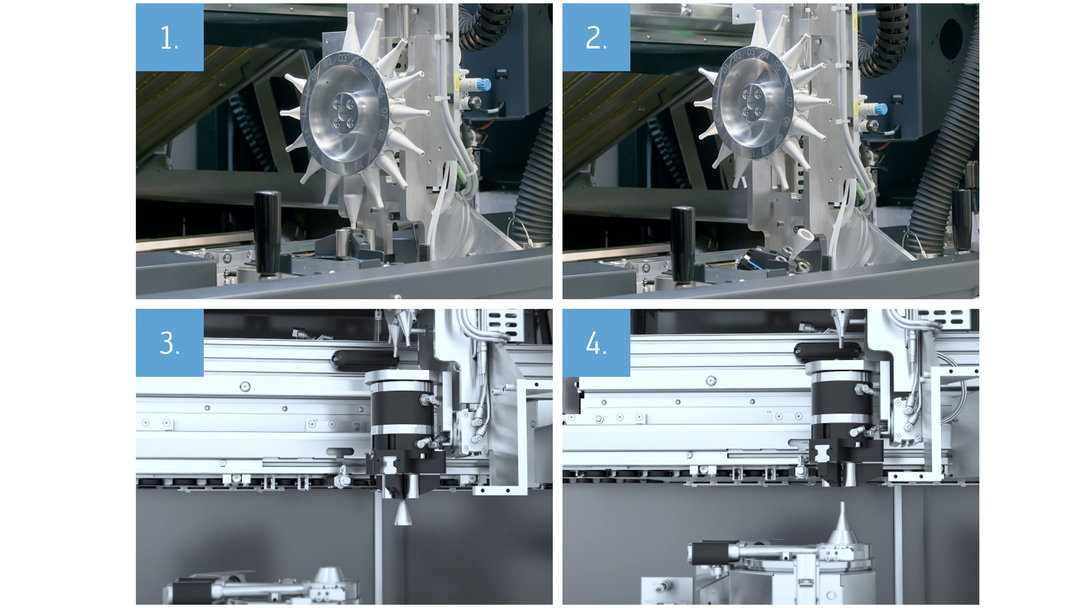

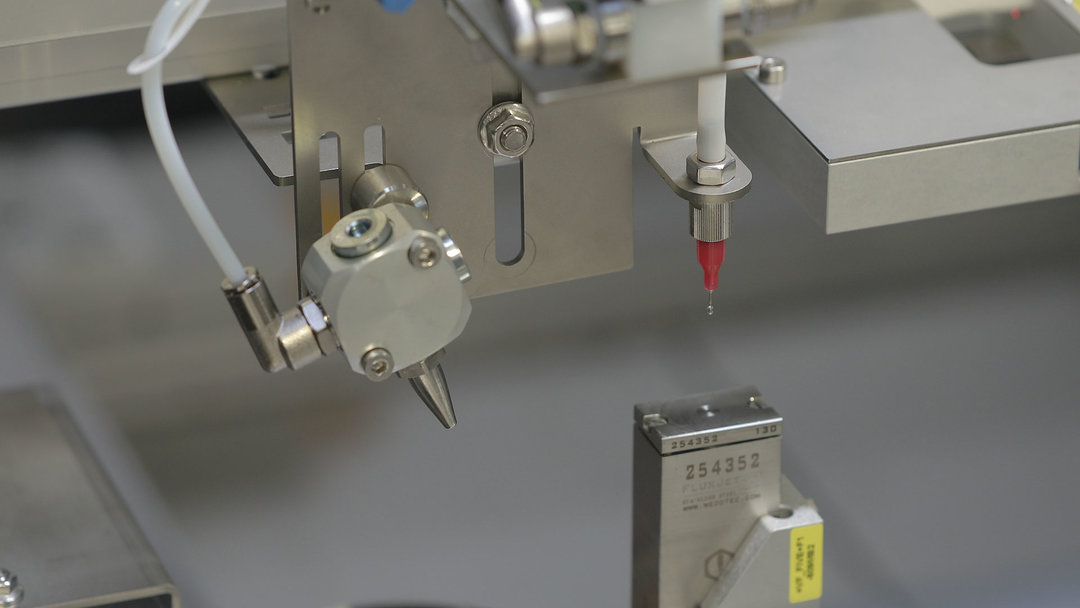

Automatic nozzle changer

The automatic nozzle changer is a new feature of the VERSAFLOW FIVE, especially for scenarios with frequent program changes and limited operator presence. It replaces manual nozzle changes, thereby increasing the efficiency and process reliability of the entire soldering process.

Segmented heating surfaces

The matrix heater consists of several segments that can be controlled individually. This enables targeted and homogeneous heating of the assemblies, even with complex boards. The segmented structure allows up to six different heating surfaces to be mapped, enabling precise adaptation to the specific requirements of the PCBs.

Automatic flux nozzle cleaning

Automatic flux nozzle cleaning significantly reduces the need for manual intervention, as it automatically removes contamination from dropjet spray heads, thus maintaining consistent spray quality. Especially during periods of low staff availability - such as night shifts or line start-ups - it ensures high process reliability and minimizes downtime.

CAD Expert Mode

The expert mode in CAD Assistant 4 enables manual routing of flux and solder modules to further optimize throughput and cycle time. This feature allows you to specify the order in which the flux modules or solder modules process a PCB. Expert mode is available in both synchronous and asynchronous modes for 2-stopper operation.