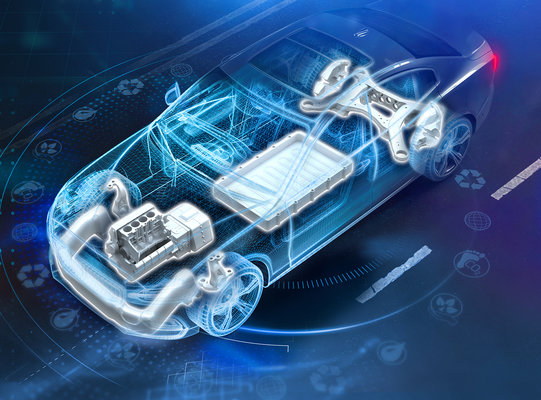

Kurtz SC Low Pressure Casting Machine

Fixed stationary unit, retractable exchangeable furnace

Kurtz Success Story Low Pressure Casting

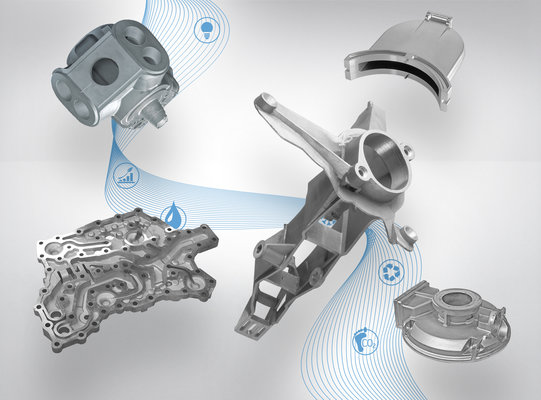

2-in-1 Machine for Permanent Mold & Sand Casting

In addition to quality and process reliability, flexibility is essential for customer foundries. With every new investment, the first question is always: Which machine is “the right one”? This is especially true for small and medium-sized foundries that do not work for the mass market. For a Turkish customer foundry, Kurtz was “by far the best choice” – according to the customer – and offered the ideal machine for the perfect solution …

Technical Highlights SC SeriesKurtz Low Pressure Casting

Closing unit with 4 solid guiding bars and 2 mold closing cylinders

Resistance furnace with thyristor control

Shuttle furnace designed for easy change of riser tube and furnace maintenance

Hydraulic system with safe, water glycol base fluid

Programmable microprocessor control (SPS) with process visualization on colour monitor, user-friendly, direct display of messages

Automatic pressure compensation for the metal used in each shot

Also available as powerful 2-in-1 solution for permanent mold and lost mold.