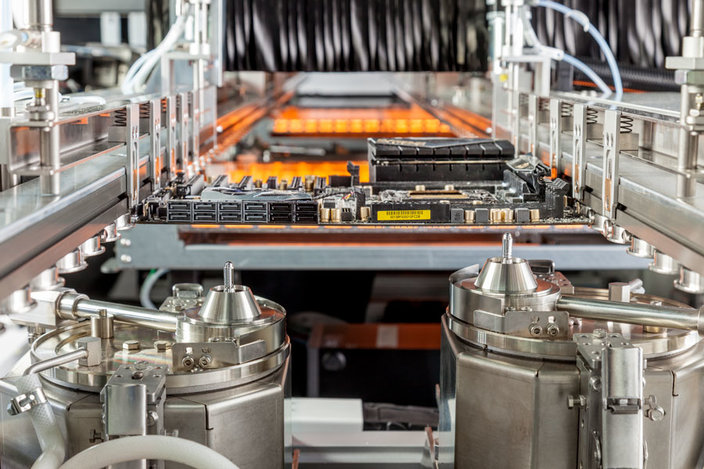

Optimize the processes of your Ersa machines!

You will receive comprehensive first-hand information on our high-end soldering systems. The theory provides an overview, while in the practical part you will experience hands-on the operation, maintenance and handling of the machine for optimum processes in your production and according to your wishes.