Since its foundation in 1982, PressFinish Electronics GmbH has been a passionate EMS service provider. Since April 2024, the company has been manufacturing electronics for its customers in the medical technology, industrial and aerospace sectors at its new 2000 m² site in Maisach near Munich. Selective soldering and paste printing technology from Ersa are also used here.

Germany currently has a hard time competing globally - too cumbersome, too high costs, too much bureaucracy. PressFinish meets these challenges with flexibility, expertise and top quality. The basis for this is a highly trained team and modern machines. “We work to make our customers happy,” summarizes Production Manager Dominik Wimmer.

PressFinish´s range of services includes the production of prototypes through to series production in batch sizes of up to 100,000 units. There is increasing demand in the development and prototype business. Here, PressFinish develops complete products on request - from PCB design and assembly to housing, software and subsequent prototype production. In the series production business, PressFinish takes care of component procurement, warehousing, final assembly and commissioning into the customer-specific sales packaging. Customers benefit from a strong team, short distances and direct communication. PressFinish is particularly valued as a partner in the aerospace, industrial electronics and medical technology sectors. For example, control units for drones, telemetry systems and - thanks to ATEX certification - explosion-proof electronic assemblies for industrial electronics are manufactured.

Challenge: aluminium laminated boards

A large proportion of production goes into medical technology. For over 20 years, PressFinish has been developing and manufacturing assemblies and devices for blood testing and processing, but also for lighting technology in operating theaters and for examination devices using LEDs as light source. One of the biggest challenges here is the soldering of LEDs on aluminum-laminated circuit boards. These special PCBs dissipate the heat generated during operation via their aluminum layer, which makes soldering the LEDs more difficult. PressFinish has specialized in this area.

To apply the solder deposit to the PCBs, PressFinish uses an Ersa VERSAPRINT stencil printer, which has a line scan camera for automatic post-print inspection in the line cycle for complete traceability. “We know exactly which components were used from which batch and can verify this production data at any time,” explains Sales Representative Franz Leitenstern.

Electronics production changed with the development of SMD technology. THT components were replaced by surface-mounted chips and BGAs, but THT components are still irreplaceable in many applications. Especially in power electronics, mobile communications technology and e-mobility, a mixed assembly of SMD and THT is often required.

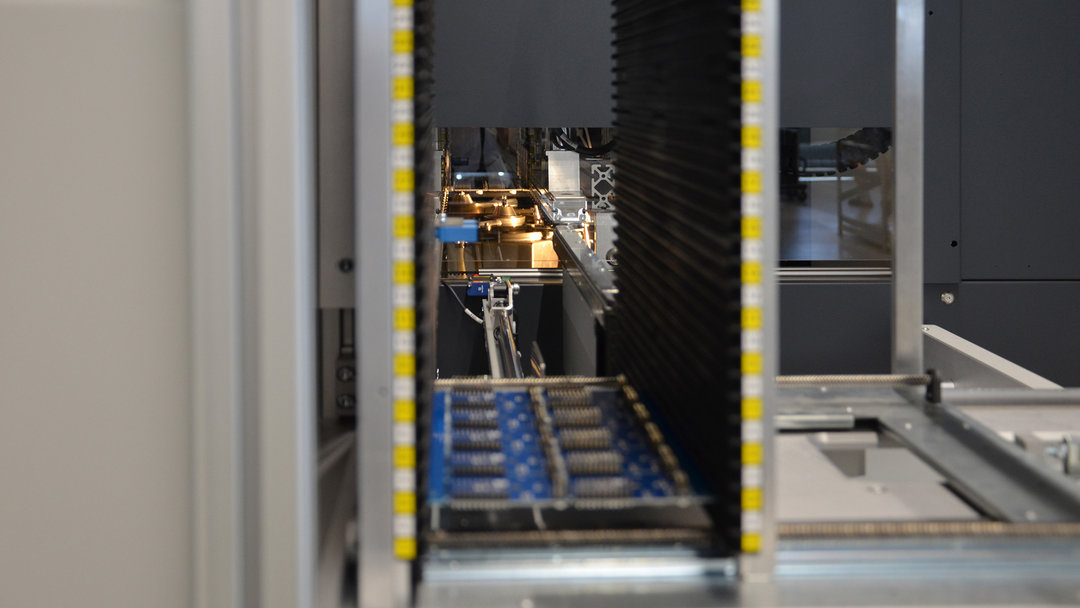

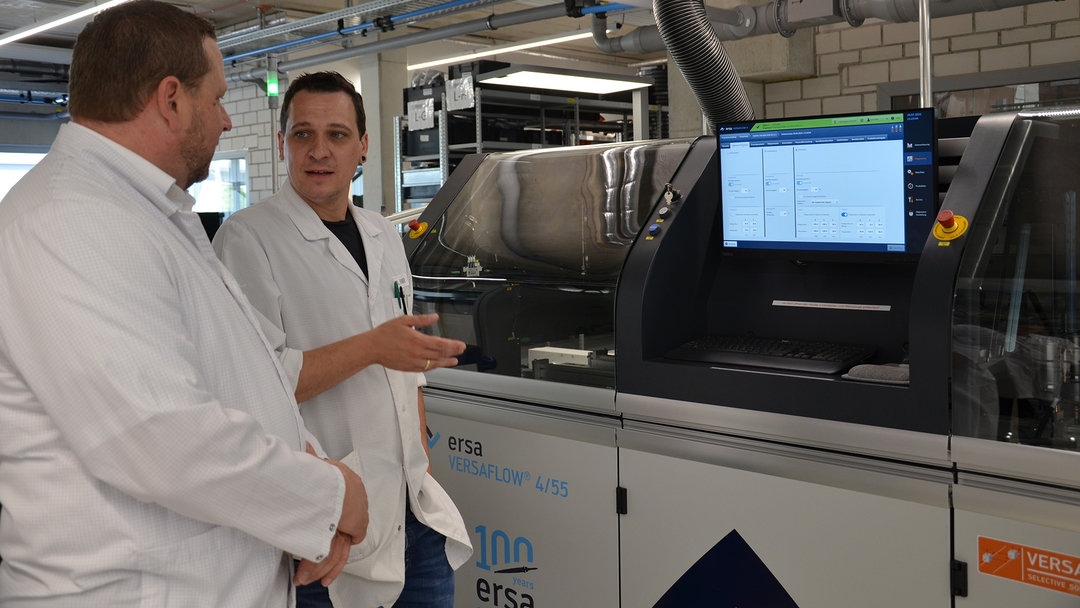

To further professionalize THT processing, PressFinish invested in an Ersa VERSAFLOW 4/55 selective soldering system in 2022, which impressed with its outstanding soldering quality, simple operation and fast set-up times. The company also uses the VERSAFLEX soldering module to process different solder joints on a PCB at the same time. This provides high flexibility and productivity. Another special feature is the complete traceability of the entire soldering process - all process parameters are recorded in detail and stored in the MES system. PressFinish relies on its partnership with Ersa to continuously expand its manufacturing expertise.

Comprehensive service and process consulting

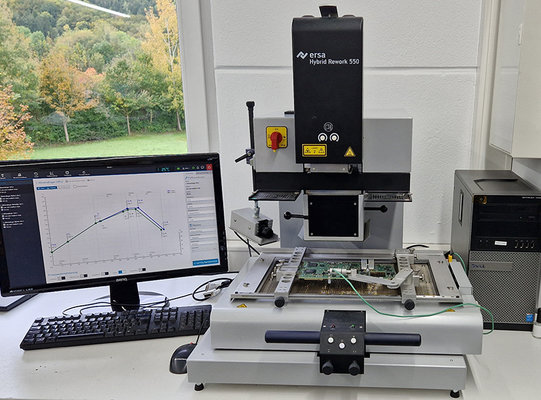

Ersa´s comprehensive service and process consulting are particularly important to the company. “Even with the best preparation and zero-defect strategies, errors can occur,” says Dominik Wimmer. For this reason, devices are already being tested in order to expand expertise in the area of rework. It is quite possible that PressFinish will also rely on Ersa here …