Fеsto Bulgaria adds automation solution to existing wave soldering system with Ersa support

With over 20,600 employees, the Fеsto Group pursues a clear global goal: to continuously improve productivity and competitiveness for customers in factory and process automation. Under the claim “Automation for a world in motion”, Fеsto has been setting standards in industrial automation technology and technical education for 100 years, thereby contributing to the sustainable development of the environment, economy and society.

In Bulgaria, where the Group has been active for 39 years, everything revolves around innovation - with 1,000 employees today and a turnover of 100 million Euro, the Sofia site has developed into a highly dynamic profit center and is one of the “top five” in the Festo Group. In order to meet the growing demand for more flexibility and efficiency, Festo Bulgaria has expanded an existing Ersa POWERFLOW PRO wave soldering system with a highly complex automation solution as part of an ambitious project.

20,000 m2 of production space, over 4,300 products - these figures alone will impress anyone who takes a closer look at industrial production. It´s easy to see why Festo Bulgaria is one of the most important production sites within the Festo family, whose headquarters in Esslingen am Neckar is just 20 kilometers from the Swabian metropolis of Stuttgart. The Festo site in the Bulgarian capital specializes in the production of electronics and electric drives, such as flow, position and pressure sensors, valve modules, PLC controls and electric motors. The Bulgarians do not want to stop at the status they have achieved; they have set themselves even more ambitious goals: They want to increase their current turnover of 100 million Euro to 300 million Euro by 2030. “We are increasingly moving away from pure hardware in the form of pneumatic and electronic products towards intelligent software solutions and seamless connectivity,” says Kalin Dobrev, General Manager of Festo Bulgaria, who declares software and connectivity to be the “basis for our future business”.

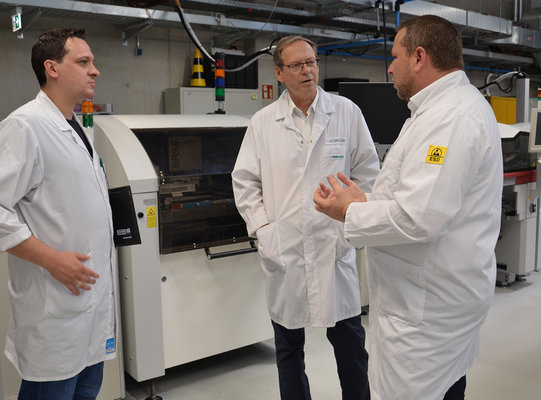

The demands on production present the electronics experts at Festo Bulgaria with immense challenges – 400 orders are received every day, 80 % of which are not planned in advance and with an average batch size of just eleven units. Festo manages its production with a high-availability strategy from order entry to goods receipt at the customer´s premises. A high-mix, low-volume approach was derived for this “production on demand” for Bulgarian electronics production in order to meet the maximum flexibility required. The soldering systems from system supplier Ersa fit these requirements perfectly and can also be adapted to changing needs thanks to their modular layout. Therefore, the next logical step was to expand the existing Ersa POWERFLOW PRO wave soldering system with automation solutions based on the Festo high flexibility strategy.

Ideal partner for smart electronics production

The business relationship between Festo and Ersa began back in 2014 - initially as a purely German-German partnership. Ersa´s headquarters in Wertheim initially delivered two VERSAPRINT 2 stencil printers to Festo´s German site in Scharnhausen, before another printer of the same type was installed three years later. In 2019, the partnership was extended to Bulgaria, which naturally benefited from the experience of the colleagues in Germany - but did not adopt it unseen, but instead started its own evaluation with a comparison to the needs at the Bulgarian site. After this was also positive, the order for a POWERFLOW PRO wave system was placed. After the first few years of successful production, a comparison was made with the strategic development - and it was determined that the existing system needed to be rethought in order to achieve future goals, with a greater focus on automated processes.

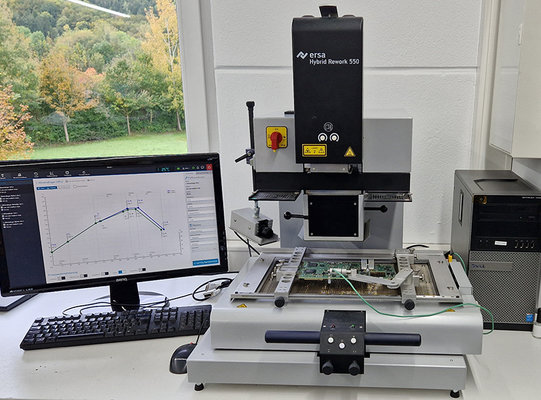

At ERSA-Bulgaria´s Technology Day 2023, a Festo engineer got talking to an Ersa Area Sales Manager, and a few months later an ambitious project was born – some of those involved still call it “crazy” to this day. In terms of content, it involved the consistent expansion of an existing wave soldering system with a tailor-made automation concept, which was implemented in intensive cooperation with the Ersa Demo Center in Wertheim, workshops in Sofia and close collaboration with the local team from ERSA-Bulgaria.

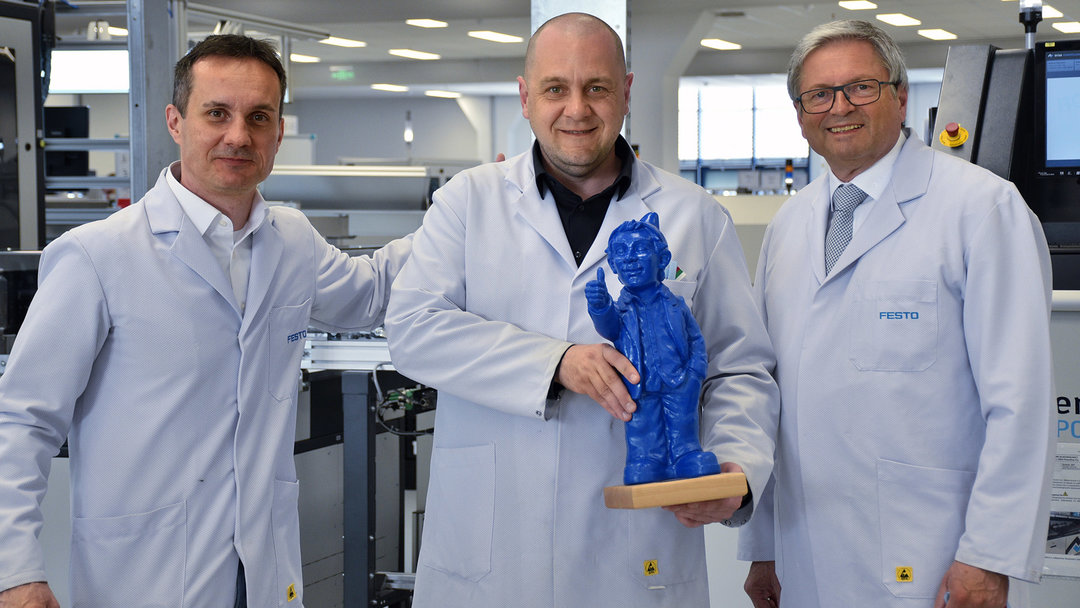

Stoyan Stoyanov, Global SMD/SMT Expert at Festo Bulgaria and one of the discussion partners at the exchange with Ersa Area Sales Manager Christian Ott at the time, describes the challenges in retrospect: “The implementation was complex - we had to ensure that the automation met our high requirements for repeatability, reliability and flexibility. Standard solutions did not work here - Ersa put a lot of effort into delivering a customized concept that was precisely tailored to our production environment. We joined forces to create 19 layouts until the final solution was found - a lot of effort, but when we look at the productive systems now: It was worth it in every respect!” The new system includes sophisticated handling technology, seamless MES traceability, barcode-controlled product identification and integrated quality checks - all embedded in a user-friendly interface with live data analysis. Where the operator was previously a potential bottleneck, automation now provides targeted support to ensure consistent quality in production at all times. Stoyan Stoyanov continues: “With our software-based solution, we are now able to produce four different products in parallel. The system recognizes the necessary parameters via barcodes and automatically adjusts the processes. That´s exactly the flexibility we need every day!”

Despite the high level of complexity, the installation went smoothly - the wave soldering system, which had grown considerably due to the upstream placement periphery, had to be moved from the second to the first floor and was able to start up directly in 3-shift operation after an intensive installation phase. The proximity to technical support was also a decisive factor: “The expertise of ERSA-Bulgaria and the close proximity is a great advantage for us - we were able to count on the fast and competent support of Nikolay Momchilov and his team at all times,” praises Stoyanov.

Sustainability and employee focus

Festo is aiming for further growth in the future, but that is not the only goal - in addition to the massive technological development towards digitization, sustainability is another central pillar of the Group. In Bulgaria, the Festo employees chose the motto „Driving our future“ to present their company. The development and production of high-tech products with the Festo brand in Bulgaria are an impetus for the sustainable development and success story of the company. And this effort is producing results: Festo Bulgaria is the winner in the “Industry” category in Lean & Green Management Award in 2024. Just two examples how the company is heading for a small CO2 footprint: Production is almost paperless, the expansion of the company´s own photovoltaic system is being massively driven forward - General Manager Kalin Dobrev´s plans include an in-house contribution of up to 45 %. At the same time, the focus is on the team, which is a decisive factor in achieving the ambitious goals.

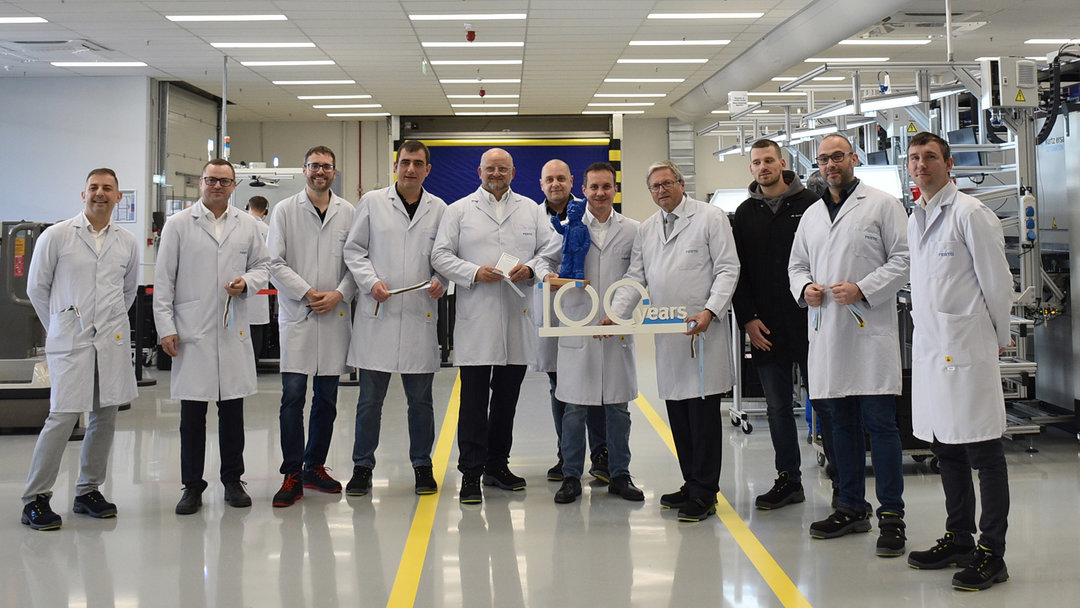

“We actively encourage and challenge our employees and make sure that life and work remain in balance,” says Kalin Dobrev. This is no empty phrase, Festo Bulgaria enjoys an excellent reputation as an employer where employees often stay for many years and is socially involved in many areas - whether socially, in sport or through direct contact with future specialists or university graduates. “Both companies, Festo and Ersa, are family businesses and represent similar values - among other things, they live business relationships as partnerships at eye level and look back on a similar company history. Ersa already celebrated its 100th anniversary a few years ago, Festo has reached 100 years in 2025. Thank you very much for the trust you have placed in us and for the project, which was realized together in true teamwork and is truly a beacon for further projects of this magnitude,” said Ersa General Sales Manager Rainer Krauss at the official handover of the plant in Sofia in mid-April 2025.

Automation at the next level

The joint Festo/Ersa project impressively demonstrates how close partnership, technical expertise and shared visions can lead to genuine innovation. With the new Ersa solution, Festo Bulgaria has done far more than just increase its production capacity - the company has made a sustainable investment in the future. “This project harmonizes perfectly with our strategy - we are convinced that it will take automation to the next level,” summarizes Kalin Dobrev. “Thanks to Ersa, we are now more efficient, more flexible and ready for the next growth steps. The Festo Bulgaria team is looking forward to further cooperation - I am sure that more projects will be coming up soon.”