Allmendinger Elektromechanik relies on professional component repair

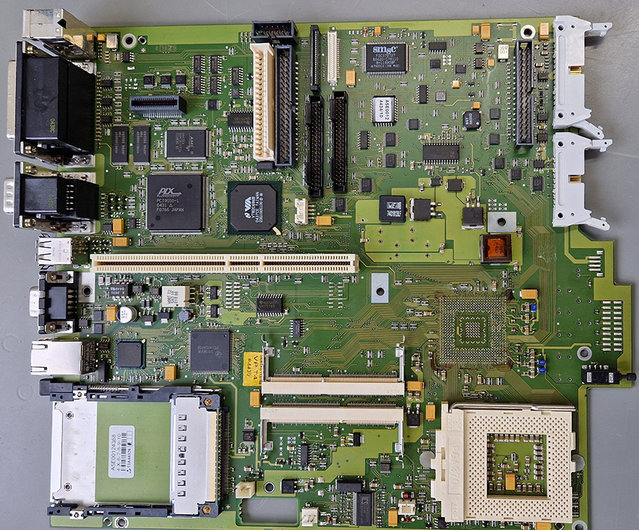

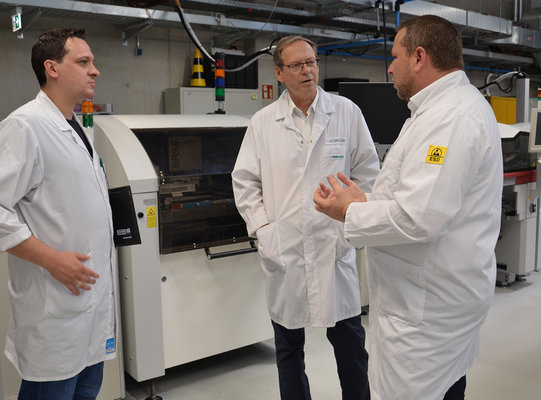

For almost three decades, Allmendinger Elektromechanik KG has been offering repairs, spare parts deliveries, on-site service and retrofit programs for CNC machines worldwide. The company from Bad Überkingen with 200 employees specializes in the repair and supply of Siemens CNC and PLC controls, servo and spindle drives as well as servo motors - whether for current or discontinued systems from Siemens, Indramat, Heidenhain, Fanuc, Bosch or Kuka. Two Ersa HR 550 rework systems, with which Allmendinger repairs electronic assemblies at the highest technical level – quickly, precisely and sustainably, play a decisive role in this.

“Our customers usually get in touch when there is an acute defect – then it has to be done quickly, that´s when our core competence comes into play,” explain Nadine and Daniel Allmendinger, Managing Directors of the second-generation Swabian family business. The service includes manufacturer-independent repairs of all assemblies at a fixed price for Siemens, Indramat, Heidenhain, Fanuc and Bosch, with direct replacement and express delivery on request. The aim is to minimize downtimes on high-quality production systems, which is supported by modern technology – over 110 test benches developed in-house, an in-house X-ray system and a 24/7 online store with direct access to more than 40,000 spare parts on 50,000 m² of storage space. This claim is based on the Allmendinger company credo: “Everything. Fast. Fair.” This can also be seen in the certifications that Allmendinger has acquired over the years: DIN EN ISO 9001 (since 2011), which sets out requirements for quality management systems, and DIN EN ISO 14001 (from 2014) for operating in accordance with valid environmental guidelines.

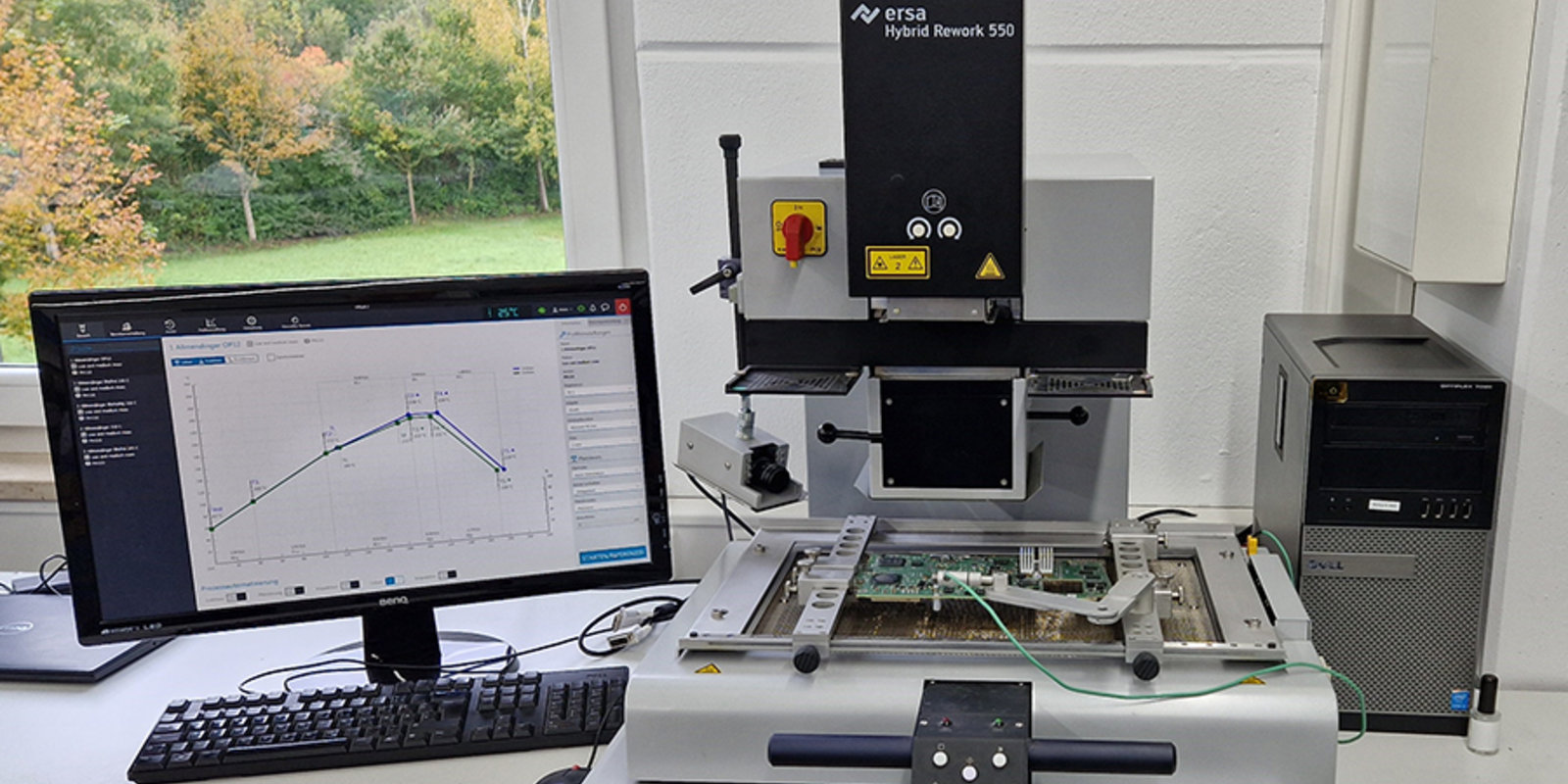

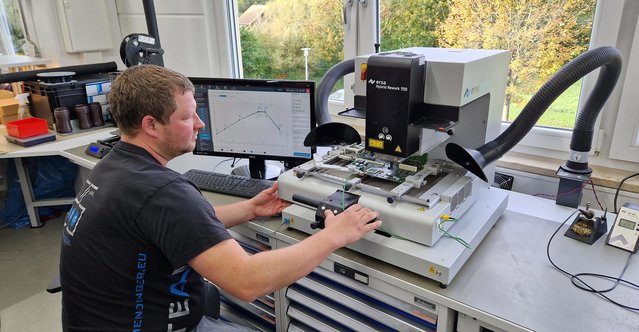

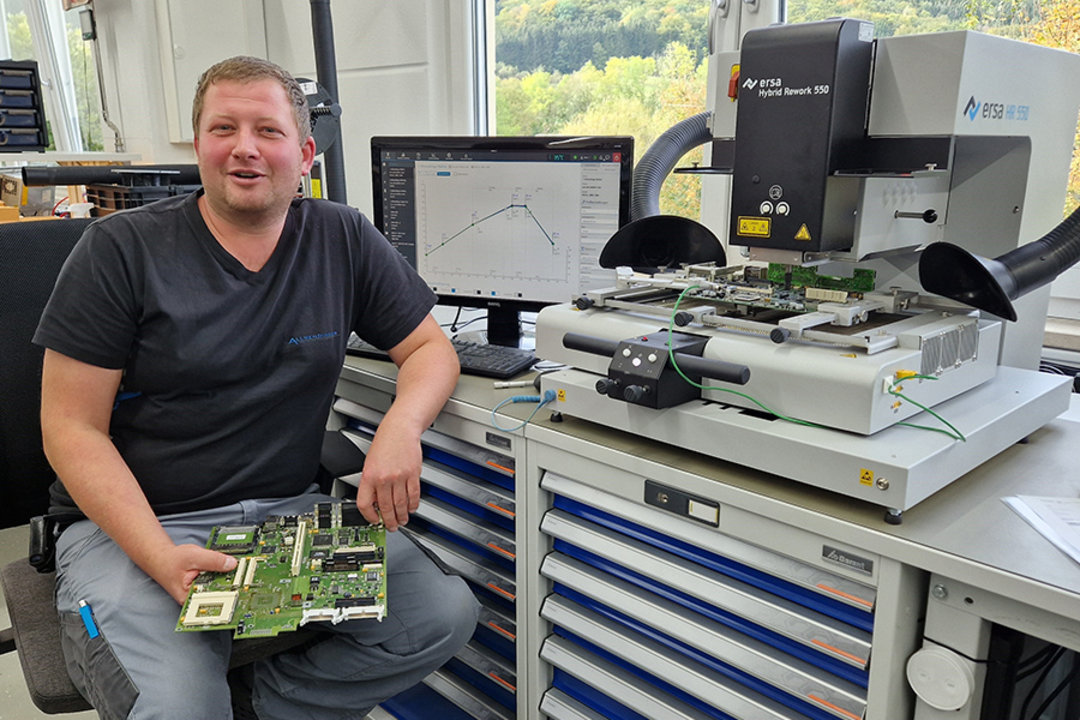

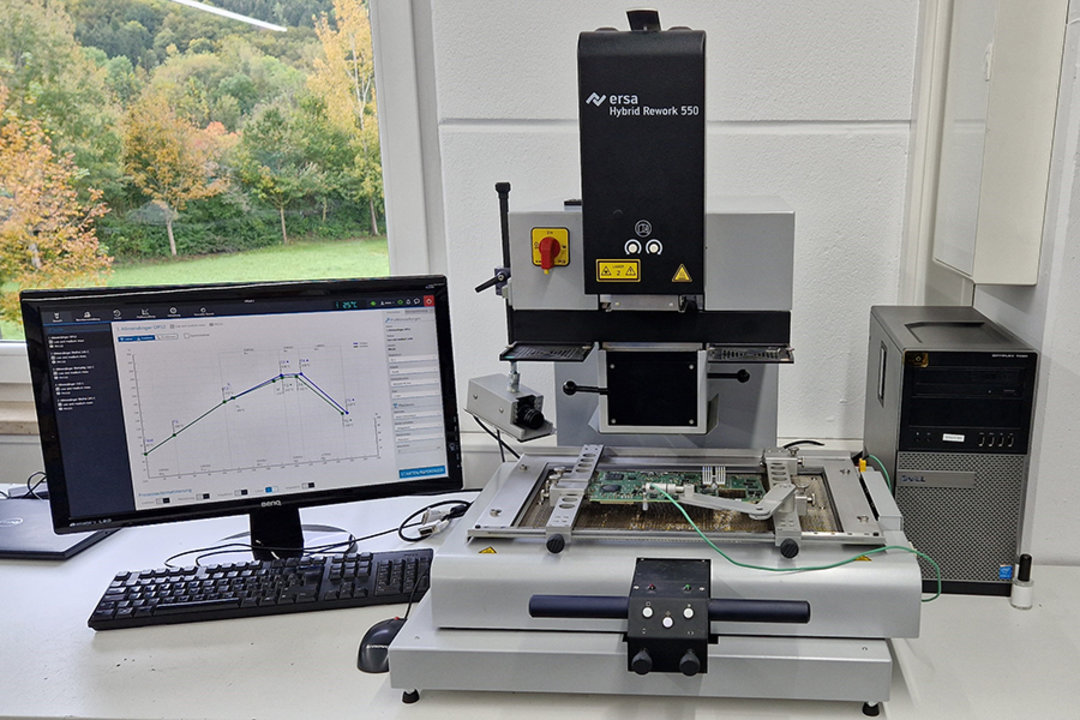

Back to the service case: error analysis and data backup are carried out at the highest technical level, for example for the Siemens Sinumerik family, Simatic panels and Heidenhain CNC controls. The Ersa HR 550 rework systems are indispensable for repairs at board level. Thanks to precise process control, high-performance optics and flexible heating technology, they also enable the reuse of components for which spare parts are no longer available – such as older controllers. These then have to be “rescued” for reuse. “Up to 40-year-old assemblies are often made functional again with Ersa systems,” says Julian Feder, workshop electronics technician responsible for assembly repair at Allmendinger since 2013. This results in approx. 60-70% leaded rework applications, which are implemented by simply selecting the HRSoft2 database profiles. If there are no special or prioritized orders, the Ersa HR 550 rework systems are in operation all day - five to ten assemblies are reworked or repaired every day.

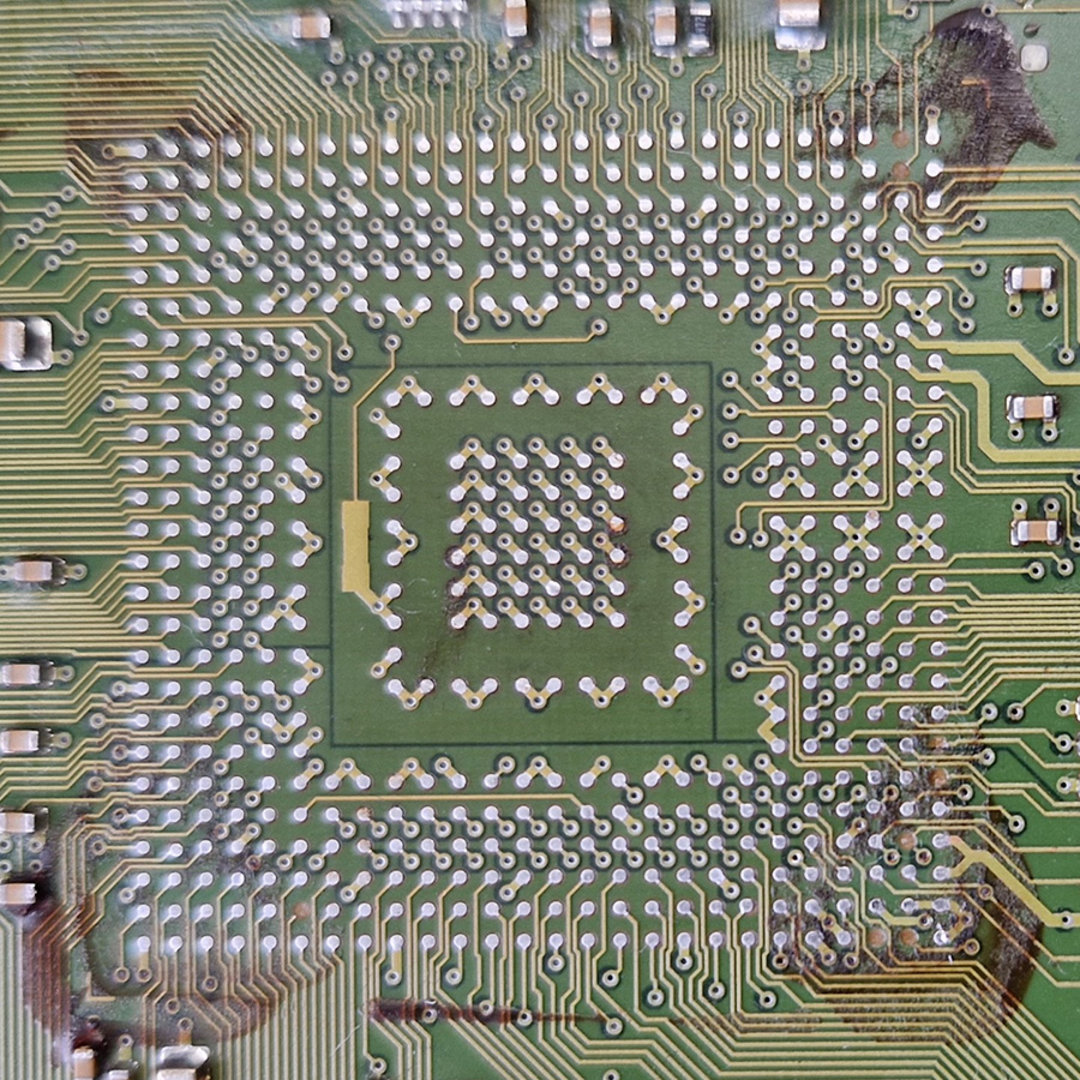

Reballing process for exisiting BGAs

The reballing process is a special case: if new BGAs, usually from China, are not available, existing chips – such as Intel or graphics processors – are remanufactured. According to Julian Feder, the success rate is around 80 percent. Even challenging tasks such as removing adhesive dots before replacing BGAs on some control modules are successfully mastered with the HR 550. Allmendinger has been relying on the Ersa HR 550 since December 2016, which achieves outstanding results with guided processes, a high-performance optics system and flexible heating technology based on convenient operation. During its time in operation, the hardware and software have been continually updated. Two such systems are now in operation at Allmendinger. It is quite possible that more Ersa soldering systems will find their way to Bad Überkingen in the future …