Ersa has been setting standards in reflow soldering for almost 40 years - from the compact entry-level model HOTFLOW ONE to the powerful flagship HOTFLOW THREE, which sets the benchmark in high-volume soldering, to the EXOS 10/26 with vacuum technology for void-free soldering results. Whatever the requirements in electronics production, Ersa reflow systems offer maximum quality, cost-effectiveness and sustainability across the board!

HOTFLOW THREE … The new benchmark in high-volume reflow soldering

The HOTFLOW THREE offers the best reflow performance in every respect: Quality. Efficiency. Flexibility. Connectivity. It runs and runs and runs in 24/7 non-stop three-shift operation for up to twelve weeks or more without a maintenance interval. With its patented three-stage Ersa SMART CLEANING cleaning system, it sets the benchmark for reflow soldering. The Ersa reflow oven is also top-class in other respects: thanks to the highly efficient motor and control units (SCPU®) developed exclusively for Ersa, only the power actually required is used in the respective zones for optimized soldering profiles and perfect soldering results, and energy and nitrogen consumption is reduced to a minimum. Ersa is thus making a clear statement for even more quality, efficiency and sustainability in reflow soldering. With a continuous sound level < 60 DB(A), it works “whisper quiet”.

Thanks to its future-proof interface and Kurtz Ersa CONNECT, the HOTFLOW THREE is ideally equipped for all digital services and precise process data acquisition. With its wide range of configurations and equipment options, the HOTFLOW THREE meets all requirements. It is available with 16, 20 or 26 zones and offers single-track or variable dual-track systems for transportation.

Highlights HOTFLOW THREE:

- Highest machine availability thanks to patented cleaning system

- Maximum ease of maintenance

- Individually adjustable convection zones

- Smart cooling system and optimum thermal insulation

- Efficient sound insulation

- Extremely flexible (2-track) transport system

- Quick soldering profile change

- Excellent & intuitive ERSASOFT 5 software

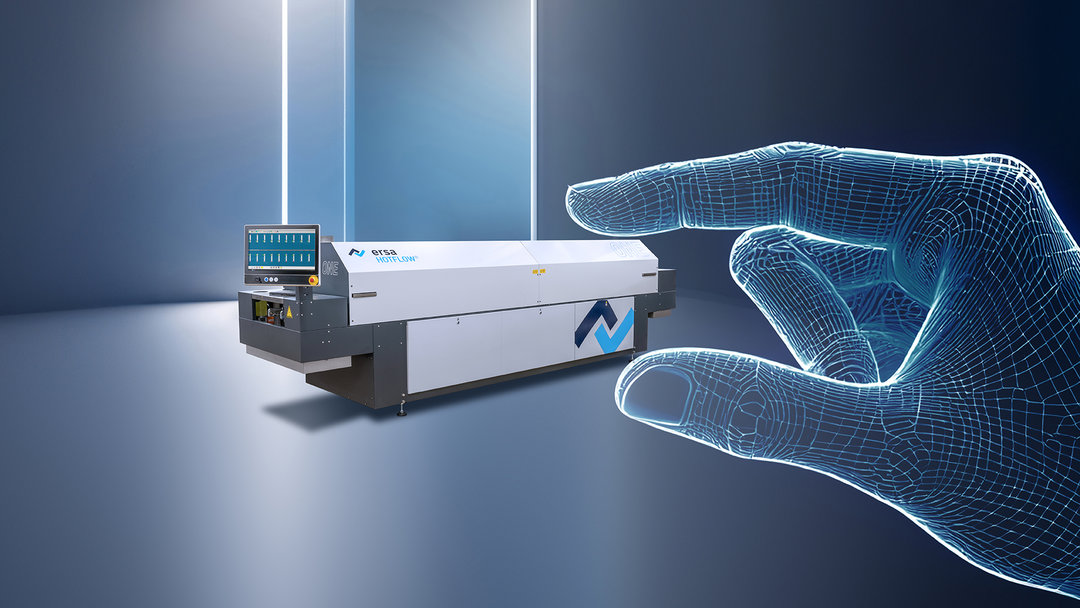

HOTFLOW ONE … High power with a small footprint!

The HOTFLOW ONE is the entry-level model in the Ersa reflow world and impresses with a strong price-performance ratio and high efficiency. The extremely compact reflow soldering system incorporates over 40 years of Ersa reflow expertise, which ensures excellent soldering results with optimum thermal performance, a good cross profile and excellent zone separation. Available with 14 heating modules with a process length of 3.35 m or with 20 heating modules (4.84 m process zone).

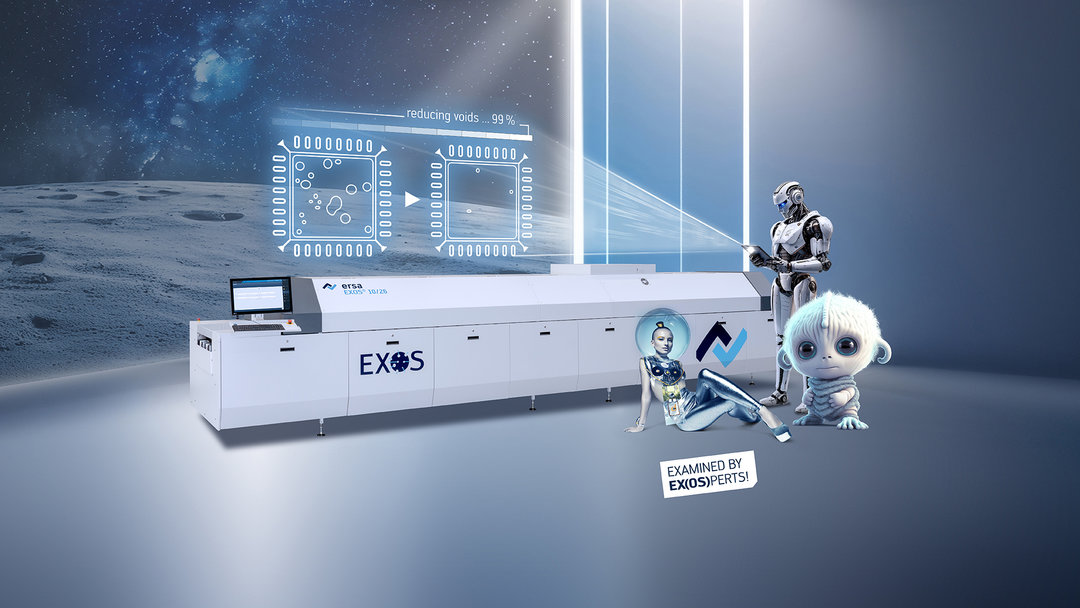

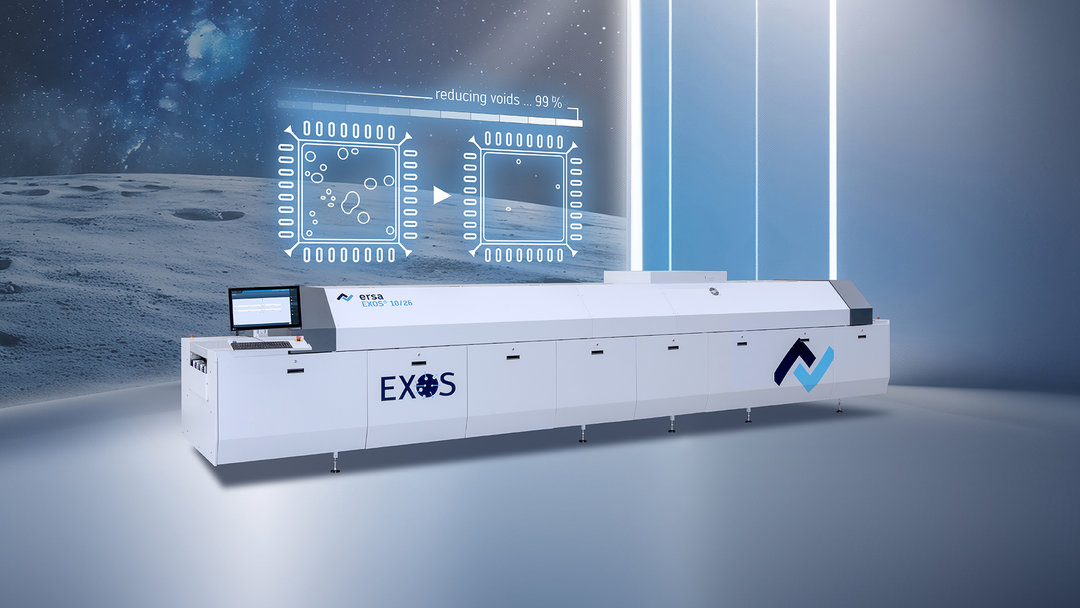

EXOS 10/26 … Vacuum reflow soldering with low void content

The EXOS 10/26 convection reflow soldering system guarantees low-void solder joints, as required in the aerospace, medical technology and power electronics industries, for example. The EXOS has 22 heating chambers and 4 cooling zones as well as a vacuum chamber after the peak zone, with which the void rate (depending on solder paste, component and PCB) can be reduced by up to 99%. The innovative transport system of the EXOS is segmented into four parts – each individually adjustable - and guarantees reliable processes and maximum component quality.