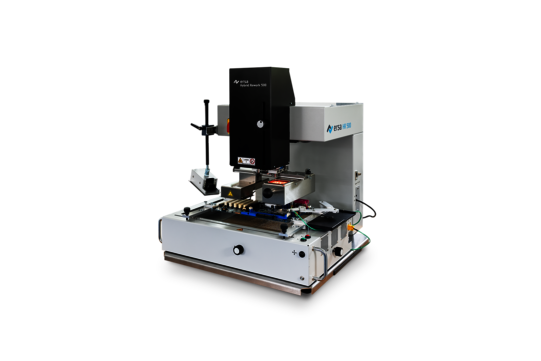

Guided Rework System Ersa HR 550 Ersa Rework

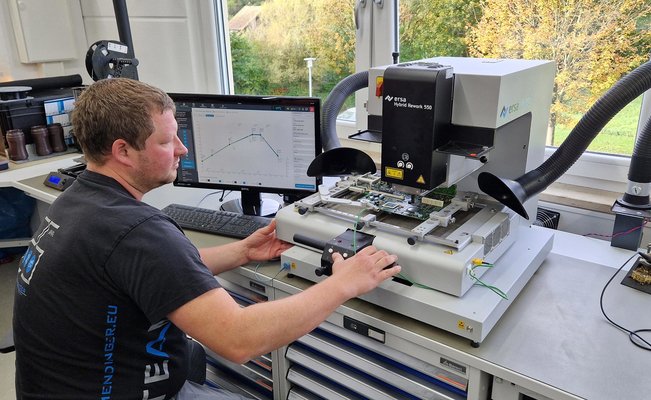

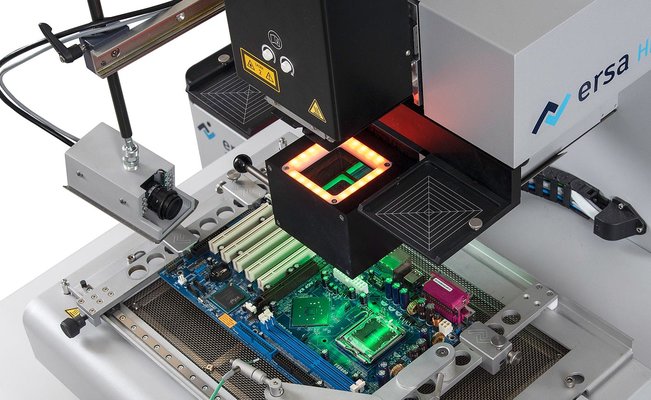

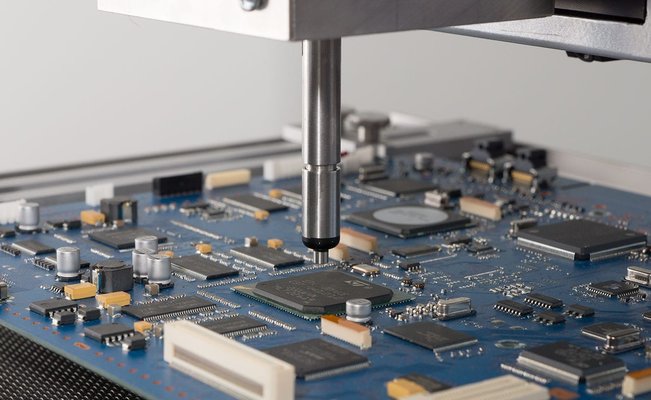

Guided rework with high-performance optical system and flexible heating technology

Thanks to guided processes, the HR 550 ensures safe reworking based on simple and convenient operation. Rating: visually leading!

Ersa Rework Systems

HR 550: smart component repair

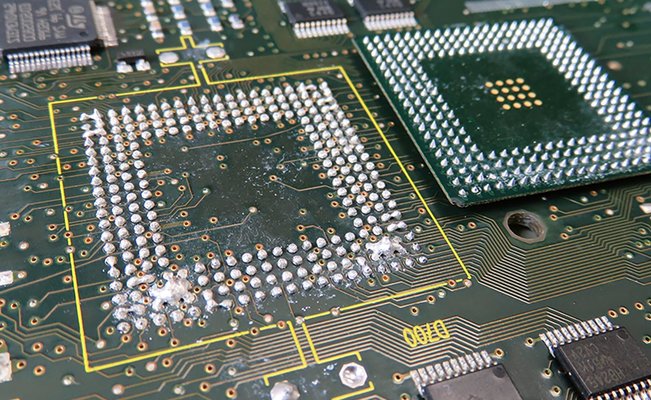

Repairing instead of throwing away is doubly worthwhile - whether for large or small assemblies. Repairing assemblies with Ersa rework systems saves costs and helps the environment. Contact us and find out more!

Highlights HR 550Ersa Rework

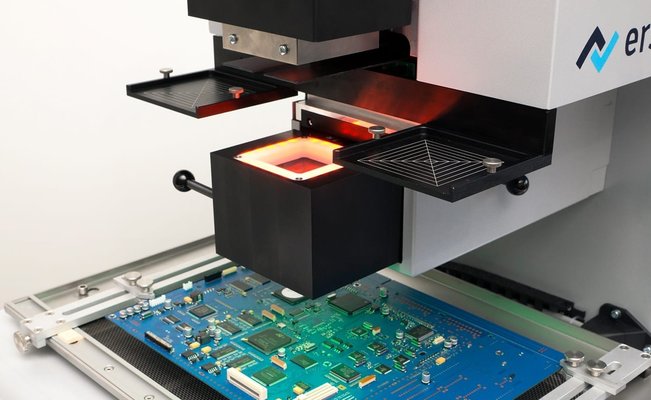

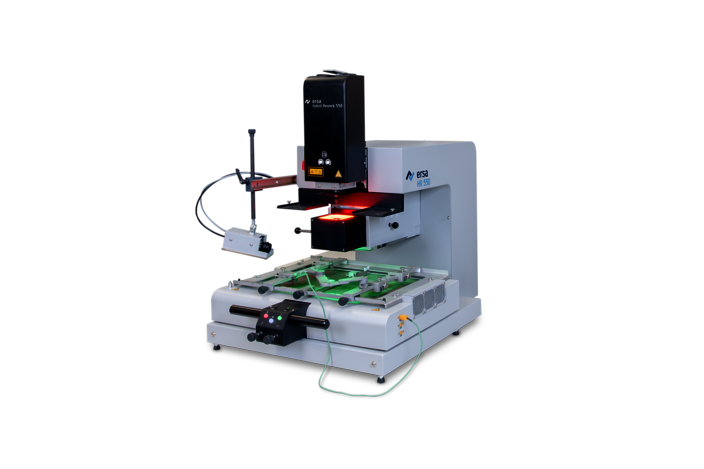

- Highly efficient 1,800 W hybrid top heating

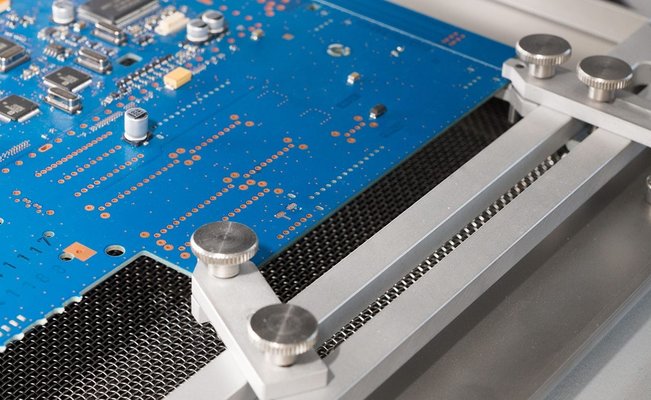

- Large-area IR bottom heating in three heating zones (2,400 W)

- Integrated vacuum pipette for component removal and placement

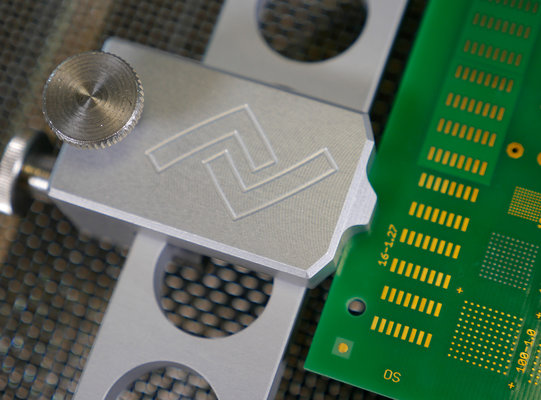

- High-precision component placement with force detection

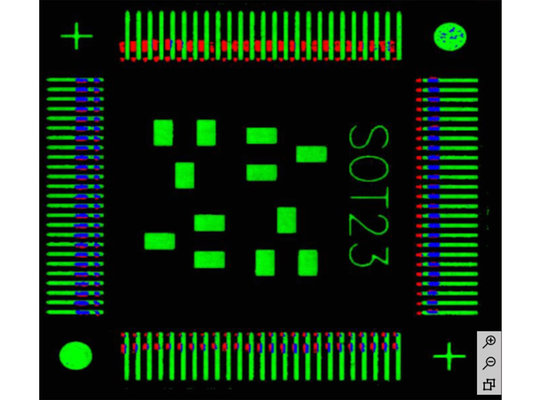

- Enhanced Visual Assistant (EVA)

- Computer-aided component placement

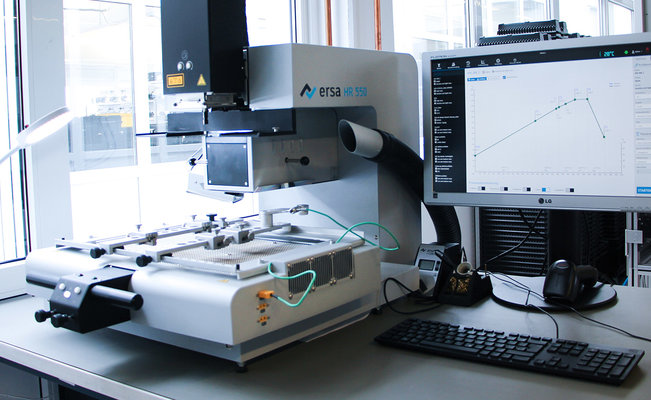

- Process control and documentation via the HRSoft2 operating software

- Suitable for use with the Dip&Print Station

Advantages HR 550Ersa Rework

The technology of Ersa rework systems ensures sustainable added value in electronics production:

- Gentle heating technology

- Sensor-guided soldering processes

- Precise component placement

- Complete process documentation

- Clear user guidance

Applications HR 550Ersa Rework

HR 550Ersa Videos

Ersa Rework System – HR 550 – product video

Ersa Guided Rework – HR 550 – Trailer

Ersa Success StoriesHR 550

HR 550Ersa Rework

Technical data

- Dimensions (WxDxH) in mm: 573 x 765 x 545/747 (heating head bottom/top)

- Weight in kg: 76

- Antistatic version (y/n): y

- Rated power in W: 4,200

- Rated voltage in V AC: 220 V - 240 VAC, 50-60 Hz, 16 A

- Top heater: Hybrid heater 900 W infrared + 900 W hot air, 70 x 70 mm

- Bottom heater: IR heater (3 x 800 W), 390 x 270 mm

- PCB size in mm: up to 400 x 300 mm (+x), up to 520 x 360 mm (+x); (0HR550L)

- Component size in mm: from 0.2 x 0.4 (01005) to 70 x 70

- Measuring channels: 3 x K-type, 1 x IRS

- Position laser: Class II

- Operating software: HRSoft 2 - suitable for Windows 8, 10 and Windows 11

- Test mark: CE

- Placement camera: 5 MP GigE color camera, field of view 70 x 70 mm (wide angle), 25 x 33 mm (telephoto)

- Option: Reflow process camera: 2.3 MP, CMOS GigE color camera, 25 mm focal length, illumination 2x LED, adjustable

Recommended accessories

Article no.:

Description

0HR510:

Reflow process camera for monitoring reflow processes

0HR550-TF:

Tapefeeder HR 550 to supply small components

0IR6500-37:

AccuTC sensor without mounting K-type for the second measuring channel

0IR4510-02:

Thermocouple cable K-type, for the second measuring channel

Dip&Print Station (0PR100):

Well prepared: defined flux or solder paste application during rework

0IR6500-01:

AccuTC thermocouple

0SC550:

Ersa SCAVENGER

Order Information

Article no.:

Description

0HR550:

Ersa HR 550 with PCB holder 400 x 300 mm (+x)

0HR550L:

Ersa HR 550 with PCB holder 520 x 360 mm (+x)

0HR510:

Reflow process camera (RPC) for HR 500, HR 550 and HR 550 XL

0PR100:

Dip&Print Station, complete

0SC550:

Ersa Scavenger - residual solder removal module, suitable for all HR 550 and hR 550 XL rework systems

Other system configurations on request