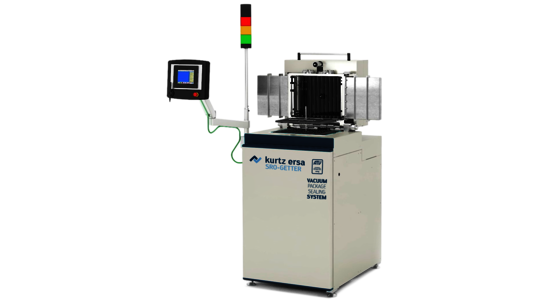

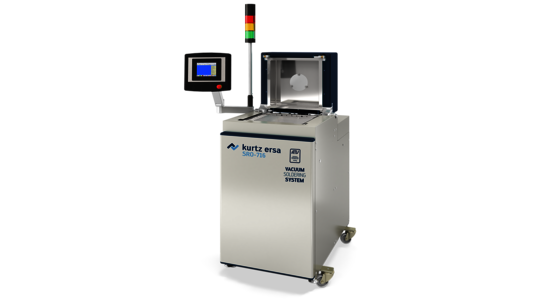

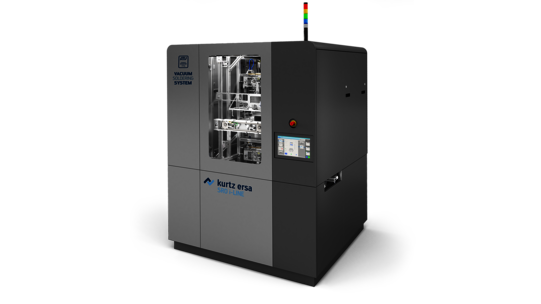

SRO-700 - Vacuum Soldering System for R&D Kurtz Ersa Semicon

The SRO-700 vacuum soldering system is for semiconductor and MEMS applications, offering 97 mm clearance over the heated surface. It can be used for vacuum soldering processes for low volume production or R&D. The cold wall chamber principle supports effective thermal management, while the IR heating technology provides consistent heat distribution. Using vacuum and formic acid, the SRO-700 ensures void-free solder joints and delivers consistent, reliable results every time.

Technical HighlightsSRO-700

- Formic acid enriched atmosphere

- Direct IR heating

- Multiple TC monitoring

- Process temperature up to 450 °C

- Oxygen <3.0 ppm with purified N2

Common ApplicationsSRO-700

- Power semiconductors (IGIBT, SiC-MOSFET)

- Sensors

- MEMS devices

- Die Attachment

- High-power LED

- Hybrid assembly

- Flip Chip

- Package sealing

Backend Semiconductor Production SRO-700Semicon

SRO-700Semicon

Technical data

Dimensions:

560 x 870 x 600 mm

Weight:

65 kg

Maximum product height:

97 mm

Heated area:

227 x 217 mm

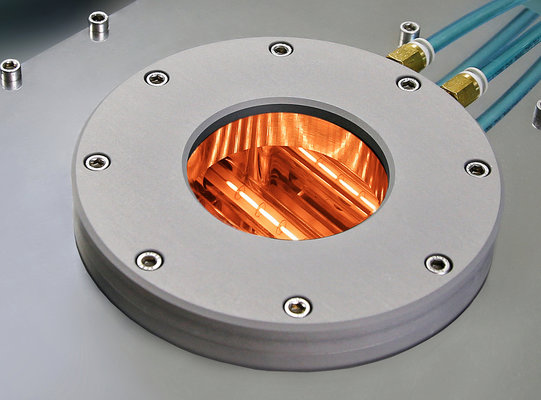

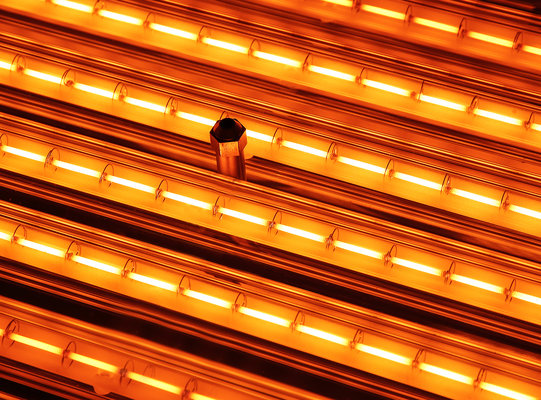

Heating method:

Arrangement of 8 IR emitters in 2 zones

Vacuum level:

<0.05 mbar

Options

- Fine vacuum

- High vacuum

- Closed loop water chiller/heater