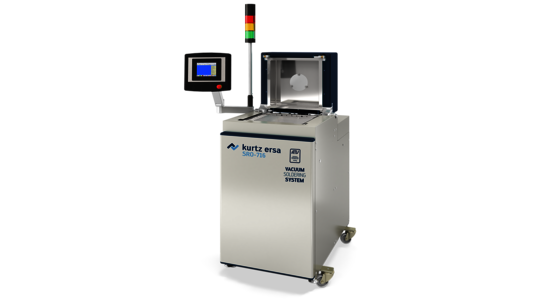

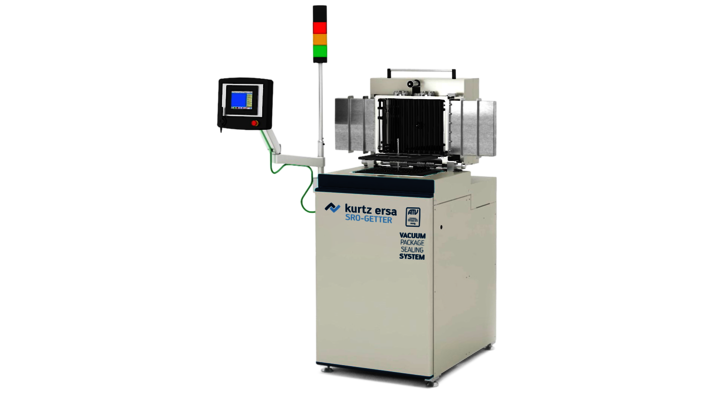

SRO-GETTER Kurtz Ersa Semicon

High vacuum packaging with thermal getter activation

The SRO-GETTER is designed to seal packages with lids, which incorporate getter material to maintain a high vacuum over the lifetime of MEMS devices like microbolometers and gyroscopes. It can be used for R&D and in production lines. The device features top and bottom IR heating with two independently monitored and controlled heating zones. It can heat uniformly up to 450 °C. Package and lid are thermally isolated during the getter activation to keep the temperature sensitive device below 100 °C. The tooling is designed specifically to accommodate the customer package and allows optimal process control and precise package-to-lid alignment. A mass spectrometer can be added as an option to the system for residual gas analysis (RGA) during the sealing process.

Technical HighlightsSRO-GETTER

- High vacuum capability

- Independent temperature control of lid and package

- Process temperature up to 450 °C

- Package and lid separated during high vacuum getter activation

- Multiple TC monitoring

Common ApplicationsSRO-GETTER

- Package sealing with high vacuum encapsulation

- Thermal getter activation

- Microbolometers

- IR detectors

- Gyroscopes

- Sensors

Backend Semiconductor Production SRO-GETTERSemicon

SRO-GETTERSemicon

Technical data

Dimensions:

1,250 x 1,760 x 1,100 mm

Weight:

240 kg

Maximum product height:

1,028 mm +/- 20 mm adjustable

Heated area:

310 x 239 mm

Heating method:

2 arrangements, each with 12 IR emitters in 3 zones

Process temperature:

450 °C

Vacuum level:

10-6 mbar

Options

- Mass spectrometer, RGA

- External cooler