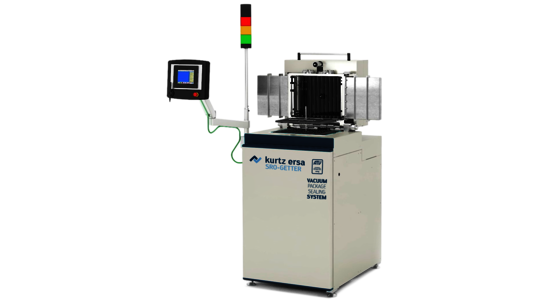

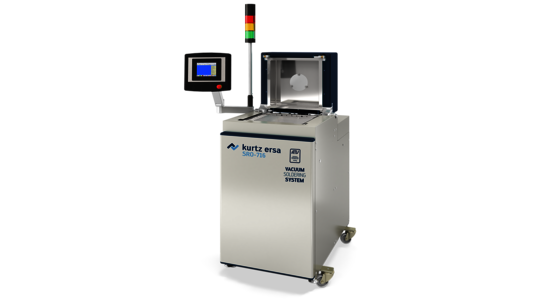

SRO i-LINE - Series system in a compact design with max. flexibility Kurtz Ersa Semicon

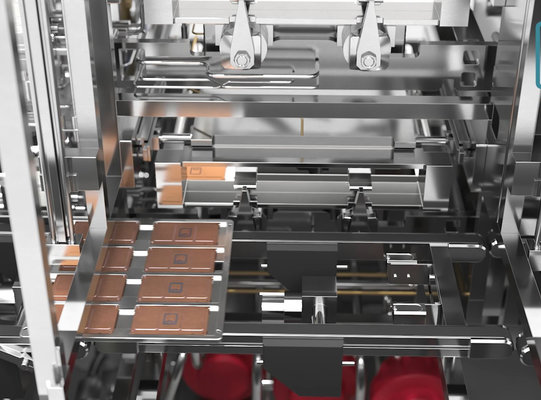

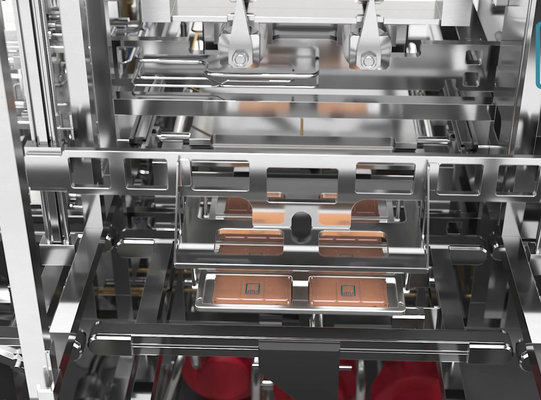

The SRO i-LINE sets new standards in series production and combines maximum efficiency with excellent process control. Thanks to its compact design and the option of integrating up to three process chambers, the SRO i-LINE maximizes production capacity without requiring additional space. Short cycle times and advanced vacuum soldering technology ensure perfect results for applications in the microelectronics and semiconductor industries. The powerful IR heating technology ensures excellent temperature homogeneity across the entire work surface, while the integrated formic acid system guarantees optimum wetting and ensures pore-free solder joints.

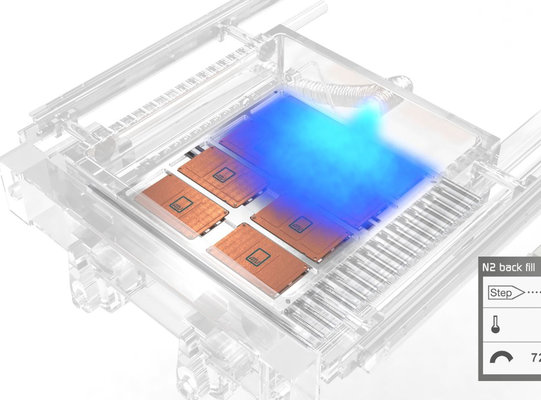

By evacuating to <1 mbar and filling the process chamber with ultra-pure N2 gas, an oxygen content of less than 3 ppm can be achieved. The SRO i-LINE enables both heating via heating plates and direct component heating. This allows even complex component geometries, such as products with integrated cooling channels, to be processed reliably. Maintenance has also been optimized to avoid production downtime: while one chamber is being serviced, production continues on two chambers. Whether used independently or as a fully integrated solution in an automated production line with high throughput, low scrap rates, and maximum process reliability, the SRO i-LINE offers a real advantage.

Technical HighlightsSRO i-LINE

- HHigh capacity: up to 3 process chambers

- Short cycle times

- Advanced IR technology

- Excellent temperature uniformity

- Process temperature up to 450 °C

- Oxygen <3.0 ppm with purified N2

- Small footprint: no change in footprint for up to 3 process chambers

- Low maintenance downtime: two process chambers can operate while one is being serviced, minimizing downtime and ensuring continuous production

Common ApplicationsSRO i-LINE

- Power semiconductors (IGIBT, SiC-MOSFET)

- Sensors

- MEMS devices

- Die Attachment

- High-power LED

- Hybrid assembly

- Flip Chip

- Package sealing

Backend Semiconductor Production SRO i-LINESemicon

SRO i-LINESemicon

Technical data

Dimensions:

1,825 x 1,735 x 2,645 mm

Weight:

1,400 kg

Maximum product height:

50 mm

Heated area:

410 x 445 mm

Heating method:

Arrangement of 18 IR emitters per chamber

Process temperature:

Up to 450 °C

Vacuum level:

<0.5 mbar

Options

- Up to 3 process chambers

- Flux managment

- Customized product carrier