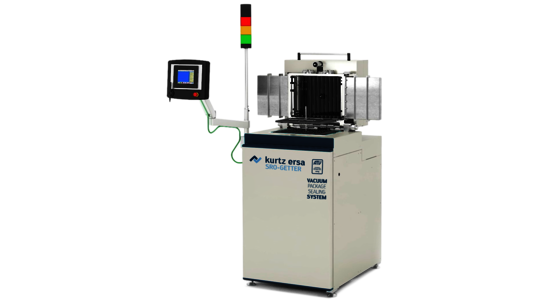

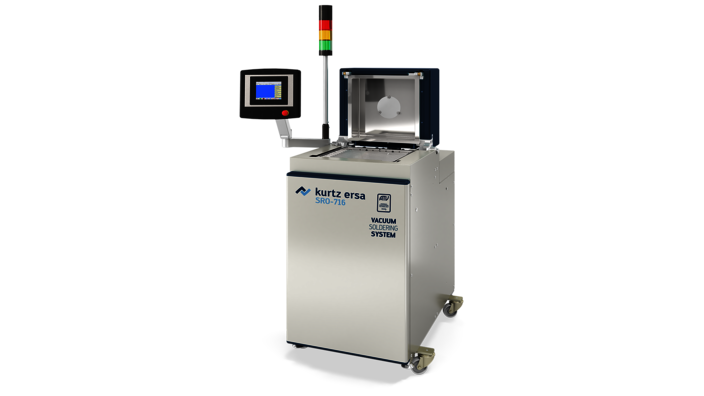

SRO-716 - System Solution for R&D and pilot production Kurtz Ersa Semicon

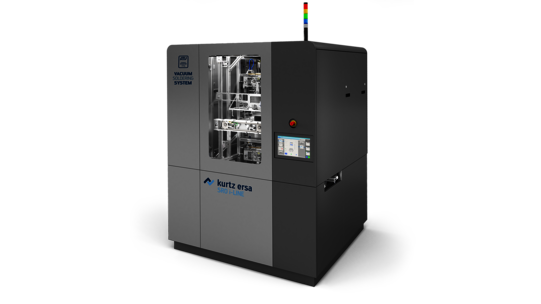

The SRO-716 is the most versatile vacuum soldering system which offers precision and reliability for a wide range of process requirements. As a central element in many R&D centers and pilot productions, it guarantees excellent results in the areas of vacuum soldering and brazing. The process chamber is heated by powerful infrared emitters up to a maximum temperature of 450 °C (optionally up to 750°C). Adjustable heating zones ensure a homogeneous temperature distribution. Formic acid creates clean, oxide-free surfaces and promotes superior solder wetting for perfect joint quality. With a heated area of 314 × 314 mm and 95 mm clearance, the SRO-716 is compatible with a wide range of electronic components and packages. Optional features such as high vacuum, overpressure, top heating, flux management for solder paste and H2/N2H2 compatibility provide maximum flexibility for various applications.

Technical HighlightsSRO-716

- Direct IR heating

- Multiple TC monitoring

- Solder paste or preform, flux-less or flux

- Exchangeable heater plate

- Process temperature up to 450 °C, optional up to 750 °C

- Oxygen <3.0 ppm with purified N2

Common ApplicationsSRO-716

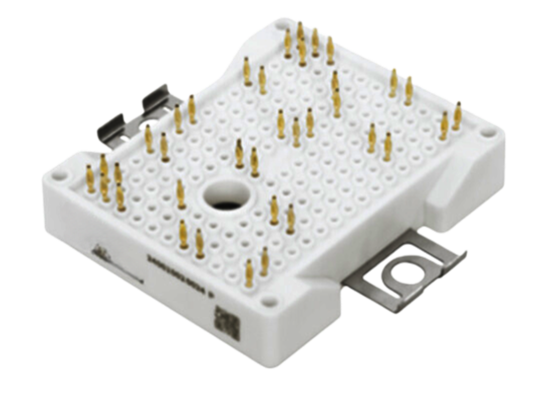

- Power semiconductor (IGIBT, SiC-MOSFET)

- Sensors

- MEMS devices

- Die Attachment

- High-power LED

- Hybrid assembly

- Flip Chip

- Package sealing

Backend Semiconductor Production SRO-716Semicon

SRO-716Semicon

Technical data

Dimensions:

1,090 x 630 x 1,830 mm

Weight:

200 kg

Maximum product height:

95 mm

Heated area:

314 x 314 mm

Heating method:

Arrangement of 12 IR emitters in 3 zones

Process temperature:

450 °C (optional 750 °C)

Vacuum level:

0.05 mbar

Options

- Overpressure

- Topheater

- H2/N2H2

- High vaccum

- Flux management

Variants

The SRO-716 vacuum soldering system can be adapted to specific requirements and offers maximum flexibility and performance for numerous applications in research and development as well as pilot line production.

- SRO-716 vacuum soldering system with overpressure

The SRO-716 overpressure system is the perfect solution for precise soldering processes that require void-free solder joints under overpressure. - SRO-716 vacuum soldering system with flux management (solder paste)

The solder paste system for the SRO-716 is the ideal solution for high-precision and clean soldering processes with solder paste. Based on Kurtz Ersa Semicon's proven vacuum soldering technology, it offers reliability and reproducibility for all applications. To ensure a contamination-free process chamber, the system is equipped with an integrated flux hood that reliably reduces chamber contamination.

- SRO-716 Vacuum Soldering System with High Vacuum

The SRO-716 high vacuum system with scroll and turbomolecular pump achieves a vacuum of <5×10-5 mbar, while nitrogen (N2) provides controlled cooling. The HCOOH step optimizes wetting and ensures excellent soldering quality. The process is intuitively controlled via the WinATV software, which allows precise adjustment of all process sequences. - SRO-716 with Topheater

The SRO-716 Topheater system was specially developed for thermally demanding soldering processes and, thanks to Topheater technology, enables extremely precise and efficient results. - SRO-716 with hydrogen

The SRO-716 H2 system is the perfect solution for removing surface oxides with hydrogen or forming gas to achieve optimum wettability.