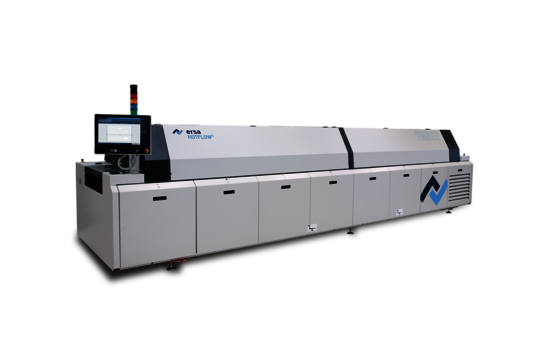

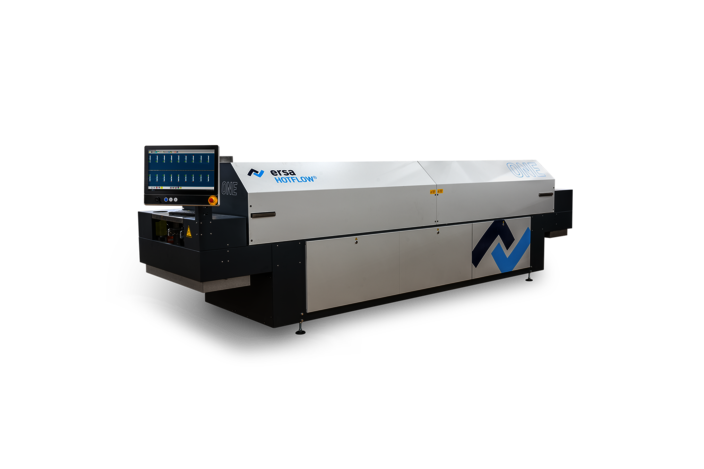

HOTFLOW ONE: Reflow soldering system with best price-performance ratio Ersa Reflow Soldering

The HOTFLOW ONE reflow soldering systems mark the entry into the Ersa reflow process - they deliver the best soldering results thanks to thermal performance, a good cross profile and optimum zone separation (available with 14 and 20 zones). The HOTFLOW ONE is characterized by an attractive price-performance ratio and outstanding efficiency. The design of the soldering system draws on 35 years of Ersa reflow success story know-how and ideally combines economic and technological solutions. The result is impressive with high reliability and availability, easy maintenance and cleaning.

Ersa Reflow Soldering

HOTFLOW ONE

The powerful entry-level reflow model with compact footprint.

Technology advantages HOTFLOW ONEErsa Reflow Soldering

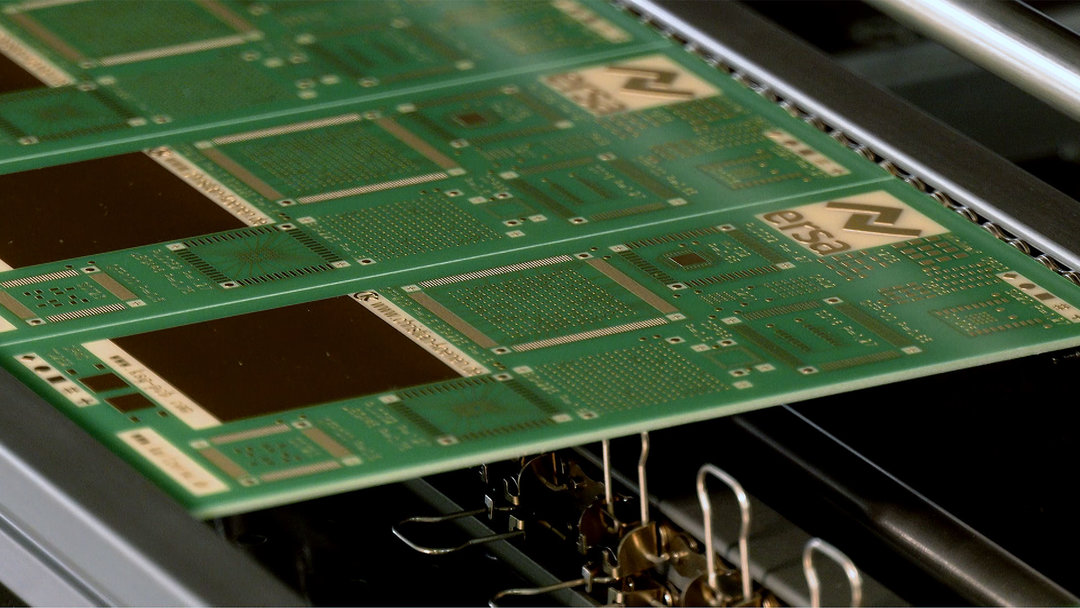

- Increased productivity through double transport

- Optimized energy transfer, minimized ΔT and increased zone separation

- Internal cooling

- Low energy consumption

- Removable heating modules at the top and bottom

- Low-mass center support

HOTFLOW ONEErsa Videos

Ersa HOTFLOW ONE - the compact solution

HOTFLOW ONEErsa Reflow Soldering

Ersa Success StoriesHOTFLOW ONE

HOTFLOW ONEErsa Reflow Soldering

Technical data

- Preheating top and bottom

- Soldering zone, convection modules top and bottom

- Cooling, convection modules top and bottom

- Low-mass transport system, 516 mm (optional Dual Track with 2x 230 mm)

- Automatic chain lubrication

- Industrial PC with touchscreen

- Operating status display

- Energy consumption management

Software Highlights

- ERSASOFT process data recording

- User-friendly ERSASOFT machine control

- Autoprofiler for fast offline profile determination

- Order management

- Online help