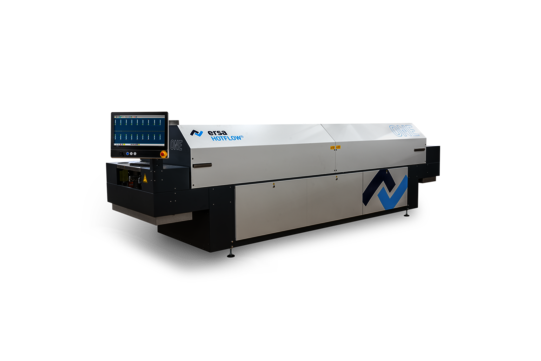

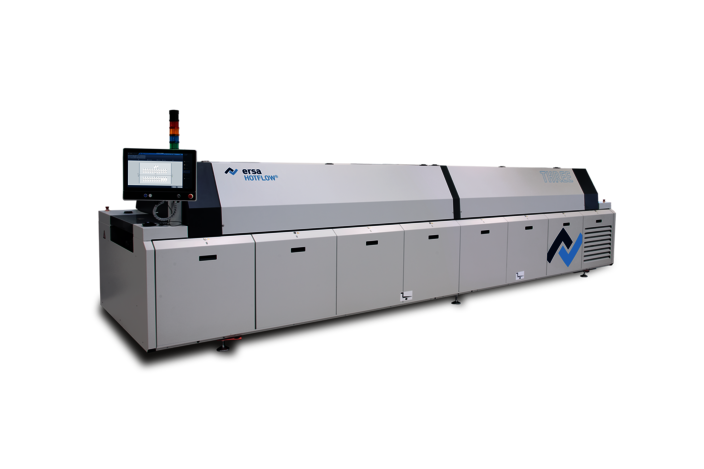

HOTFLOW THREE: A new era in reflow Ersa Reflow Soldering

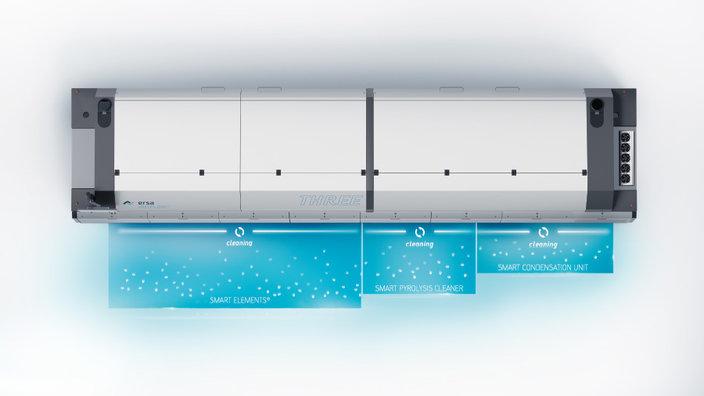

HOTFLOW THREE: the best reflow performance in every respect: Quality. Efficiency. Flexibility. Connectivity. Cleaning. It runs and runs and runs and sets the benchmark for reflow soldering with 12 weeks and more of non-stop operation without maintenance intervals. This is made possible by the patented three-stage Ersa SMART CLEANING system consisting of the new SMART ELEMENTS® filter system, the SMART PYROLYSIS CLEANER in the peak zone and the SMART CONDENSATION UNIT in the cooling zone.

1/3

Ersa Reflow Soldering

HOTFLOW THREE

Runs and runs and runs ...

Inspiring machine availability (OEE) thanks to the 3-stage Ersa SMART CLEANING system with perfect accessibility.

Features: less maintenance, increased Overall Equipment Effectiveness, higher throughput and performance and fast cooling/profile changes

2/3

Ersa Reflow Soldering

HOTFLOW THREE

Highest soldering quality!

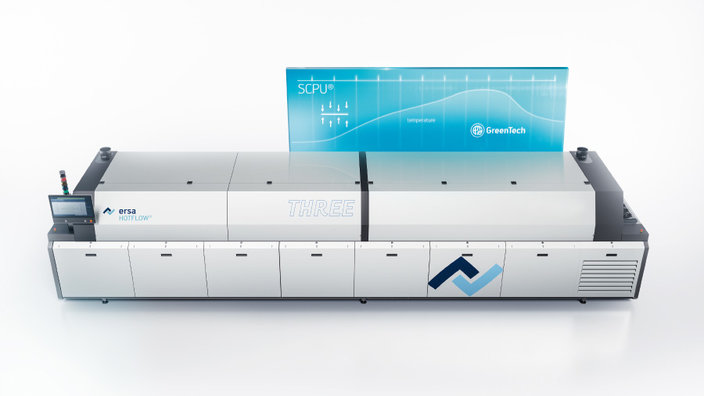

The new, unique SMART CONVECTION POWER UNIT (SCPU®) enables unprecedented soldering quality. The perfectly coordinated motor control works highly efficiently and reduces energy consumption.

Features: Benchmark in reflow soldering, more performance, reduced energy consumption, sustainable production

3/3

Ersa Reflow Soldering

HOTFLOW THREE

Future-proof user interface for precise Industry 4.0 data

With excellent and convenient software for intuitive operation and precise process data acquisition.

Features: maximum user-friendliness, user-friendly industrial PC with touchscreen, simple MES connection thanks to standard interfaces, real-time data thanks to standardization, traceability (process information)

Advantages HOTFLOW THREEErsa Reflow Soldering

Impressive machine availability (OEE) thanks to the 3-stage Ersa SMART CLEANING system with perfect accessibility.

- Less maintenance

- Increased Overall Equipment Effectiveness

- Higher throughput and performance

- Fast cooling/profile change

HOTFLOW THREEErsa Videos

Ersa Reflow Soldering – HOTFLOW THREE – product video

Features HOTFLOW THREEErsa Reflow Soldering

Even more quality in soldering

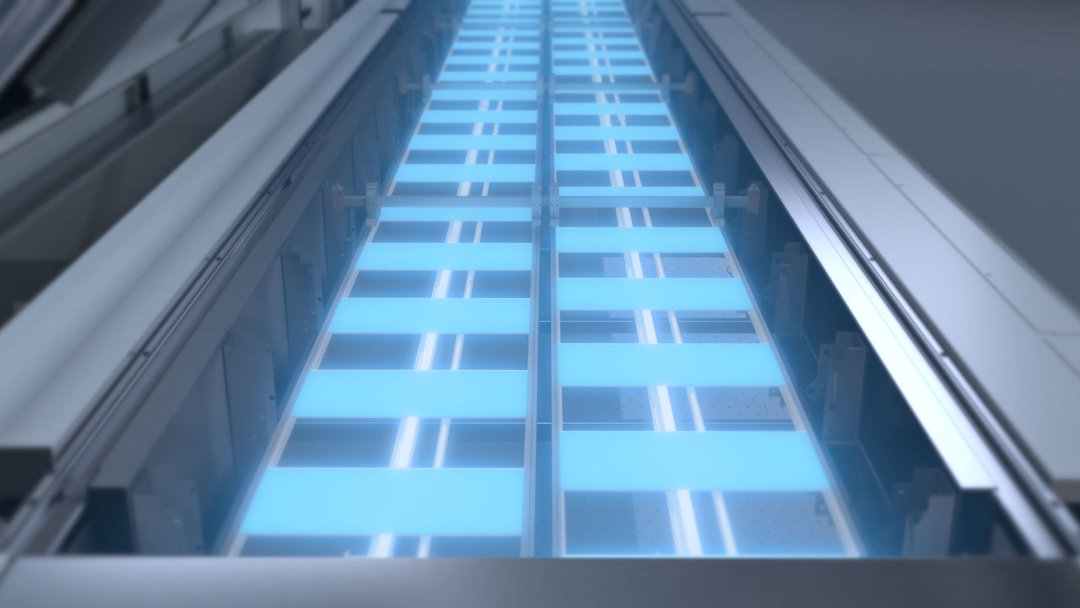

With the HOTFLOW THREE, Ersa is making a clear statement for even more quality in soldering. An absolutely unique feature: the SMART CONVECTION POWER UNIT (SCPU®). The exclusively developed motor and control unit ensures an optimized soldering profile and thus even better soldering results. Individual zones can be controlled individually, enabling perfect adaptation to the requirements of the material and solder paste.

Variable transport system

The HOTFLOW THREE, available with 16, 20 or 26 heating zones, offers single-track and variable dual-track systems for transporting PCB widths of up to 686 mm (single track) or up to 2x 300 mm or 510 mm wide (dual track). All versions have a center support that can be optionally activated or deactivated. The HOTFLOW THREE also impresses when it comes to maintenance - servicing the cooling zone and cleaning the filter systems is simply carried out from the front.

Intuitive User Interface

The HOTFLOW THREE is easy to operate! Its industrial PC with touch screen and the intuitive ERSASOFT 5 make soldering program creation and management extremely convenient and future-proof. Thanks to the new, exclusively developed motor and control unit SMART CONVECTION POWER UNIT, the HOTFLOW THREE delivers exact process data from each individual zone.