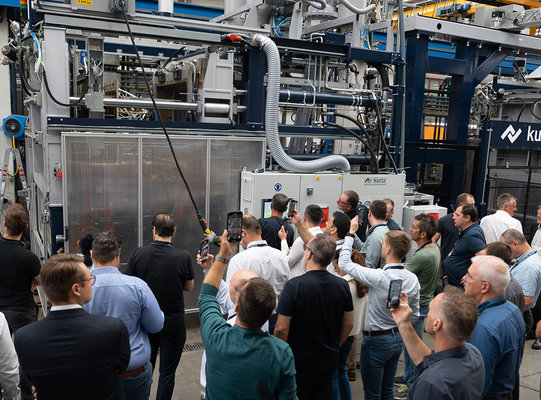

The K show is the leading trade fair for the plastics industry and, for our Protective Solutions division, it is also the most important trade fair in Europe. Kurtz customers also make the pilgrimage to Düsseldorf every three years. A group of customers heading for K, mainly from Central and South America as well as Asia, stopped off at Kurtz headquarters and our locations on the left and right banks of the Main River from October 5 to 7. The „Kurtz Ersa Germany Tour” offered sales partners and colleagues from overseas the opportunity to get to know our group and gain valuable insights into our product world and processes.

Perfectly attuned to the theme of innovation, these customers moved on to Düsseldorf to discover trends and innovations in the plastics industry. After three years of intensive preparation, K 2025 opened its doors on October 8. Our well-prepared team welcomed visitors to our booth with new developments and live demonstrations. These included the Kurtz WAVE FOAMER M, which was used to produce sustainable, steam-free floor cushions made of rEPS from Storopack - a raw material consisting of almost 100% post-consumer material.

Semi-automated Tool Change

The Kurtz PRO FOAMER M attracted a great deal of attention – originally, the semi-automated tool change was to be demonstrated twice a day. However, this plan was abandoned on the very first day and, due to individual customer requests, we demonstrated the tool change almost continuously. What makes it so special is that no more than one person is needed to change the tool! The worker is guided through the individual steps on the screen; no ladders or other aids are required. This means that even untrained personnel can carry out the changeover safely and quickly.

Integrated Part Weight Control

Another highlight and world first in particle foam processing was the Kurtz part weight control system, a system for actively controlling the weight of molded parts. This will make product quality even more reproducible in the future, while further minimizing reject rates. In addition, the weight of the molded part is known immediately after filling – no waiting until drying to determine it. Property rights for the system have been registered.

New Demolding and Stacking Technology

In the past, linear handling systems were mounted on Kurtz Shape Moulding Machines. This was inexpensive and efficient, but there was room for improvement. Our new linear system is decoupled from the shape molding machine and has its own mounting, which means that movements of the machine frame cannot affect the system. This enables significantly higher travel speeds, which reduces the cycle time by 4 to 5 seconds, depending on the machine size. The control system is linked to that of the shape molding machine and setting parameters can be saved as usual with the tool recipe.

Process as the Key to Greater Efficiency

The Process Analysis Tool was also an eye-catcher – it can be used to determine the status of the shape molding machines, record and superimpose process curves, and finally evaluate them together with process specialists. This is a new service offered by Kurtz for the analysis and further development of processes in order to achieve the highest quality and efficiency.

Innovation at Kurtz and at the VDMA Booth

Kurtz participated in the VDMA program and exhibited a food crate made from biodegradable raw materials in the pavilion. Sales Manager Sebastian Schreck presented the possibilities offered by sustainable raw materials and how energy-efficient they can be processed on the Kurtz WAVE FOAMER.

Stephan Gesuato, General Manager Protective Solutions, about the K appearance of Kurtz: “Our visitors confirmed that we had picked the right topics. They rewarded us with high attendance at our booth throughout the entire trade fair. This motivates us to continue working hard on innovations that benefit our customers. Thank you very much!”