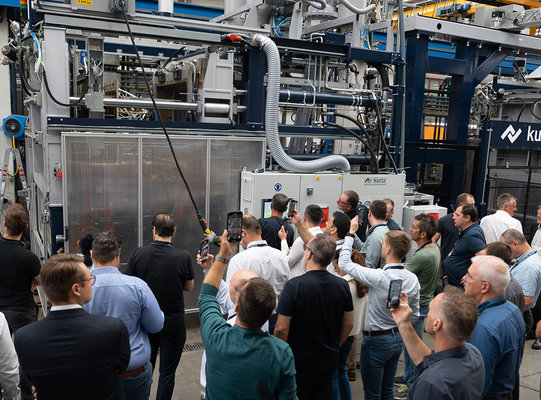

Kurtz low-pressure casting machines are primarily used in the automotive supply sector. With complete casting lines including automation, high-quality parts such as chassis parts, battery housings, electric motors, crankcases and components for high-voltage technology are cast in aluminum.

Kurtz has specialized in the construction of low-pressure casting machines since 1983 - and we have also been producing these machines in China for one year now. In July 2025, we presented a low-pressure casting machine “made in China” for the first time at the renowned “China Die Casting” in Shanghai, the country´s most important trade fair for the foundry industry. The enthusiasm at the stand and the positive feedback from our customers confirm that it was the right step to build casting machines “from China for China”.

Production directly in China enables us to achieve shorter delivery times and a lower CO2 footprint, as there is no need for costly transportation from Germany to Asia. This measure also helps us to survive the intense price competition. Kurtz remains true to its principle: “affordable yes, cheap no”!

Short distances for fast accessibility

The aim is to design “made in China” machines not only for the Chinese market, but also to offer them throughout Asia and worldwide. Service is provided by the nearest Kurtz location, be it in the United States, Mexico, China or Germany. The “shortest route” plays a decisive role in ensuring the fastest possible availability. Up to now, we have already sold and manufactured four AL22-17FSC machines. One of these is for our partner KPMC in China, a tool manufacturer based in Kunshan near Shanghai. KPMC uses our machine to cast the molds it produces directly in its factory for the customer for the first time.

With KPMC, Kurtz has set itself the goal of offering our customers more than just a machine. As a team – Kurtz, KPMC and the customer – we work together to develop and produce the optimum process and the right tool to ensure an immediate and smooth start of production at the customer´s plant.

Regionally different casting processes

We have found that the casting processes in China and Germany each have their own approaches. Our aim is to combine KPMC´s valuable knowledge from China with Kurtz´s proven experience. The result will be intelligent gating systems that optimize the material cycle and reduce pre-processing. In addition, we offer practical workshops and training directly on the machine and on the cast part, even before the customer puts their own machine into operation. KPMC also has the option of casting the first parts directly for the end customer using the “original casting machine” if required. This approach enables to deliver the first prototypes to the end customer extremely quickly, while these efficiency gains enable KPMC and Kurtz to build the casting machines optimally and with less time pressure. Flexibility and creativity are of central importance here.

This approach creates a real win-win situation for us and our customers. Our experience so far - both from the Kurtz team in Germany and China as well as from our partner KPMC and the feedback from our customers - encourages us on this successful path. By working closely with our partners and customers, we are creating a platform for sustainable success and efficient production processes.

We look forward to shaping the future of foundry technology together with you and setting new standards for quality and efficiency!